A kind of improved method of garnet type solid electrolyte

A solid electrolyte, garnet-type technology, applied in the field of energy material preparation and electrochemistry, can solve the problems of no prospect of large-scale application, difficulty in meeting battery power density, limited improvement in electrochemical performance, etc., and is conducive to large-scale High production, high utilization rate, avoidance of side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 1. Processing LLZTO ceramic sheets

[0038] Prepare the treatment solution: Dissolve 10 mg of ammonium fluoride in 10 ml of isopropanol.

[0039] Treatment of ceramic sheets: Take 10 microliters of treatment solution, apply it on the surface of LLZTO ceramic sheets, the thickness of the liquid film is 100 microns, and then conduct a heating reaction at 400 degrees Celsius.

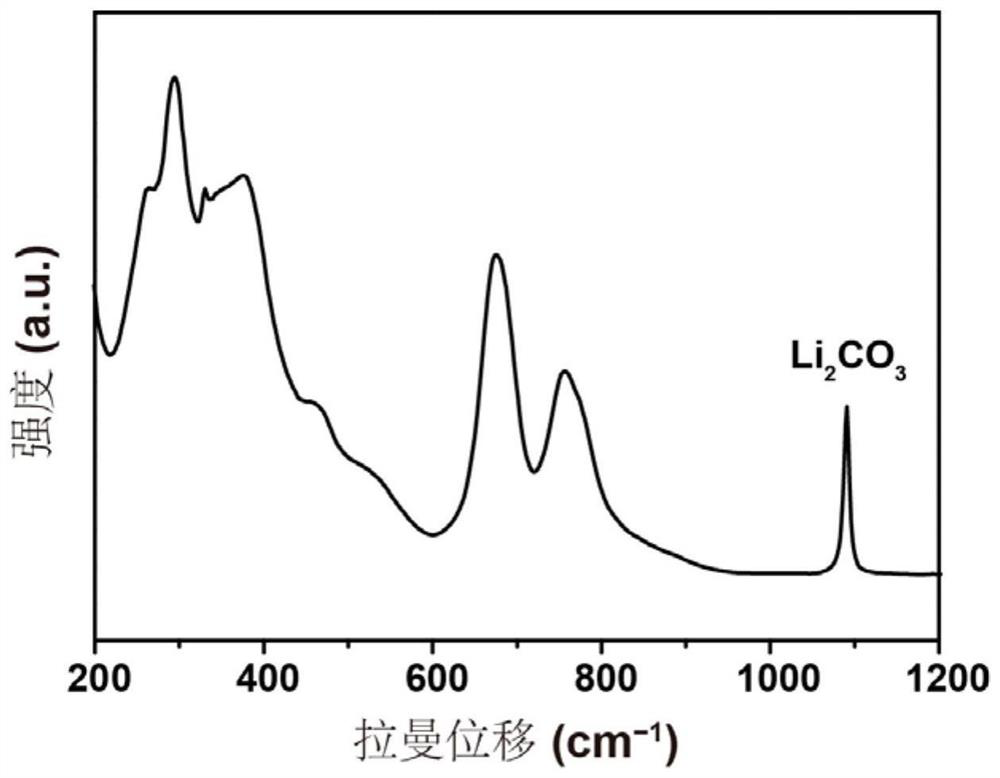

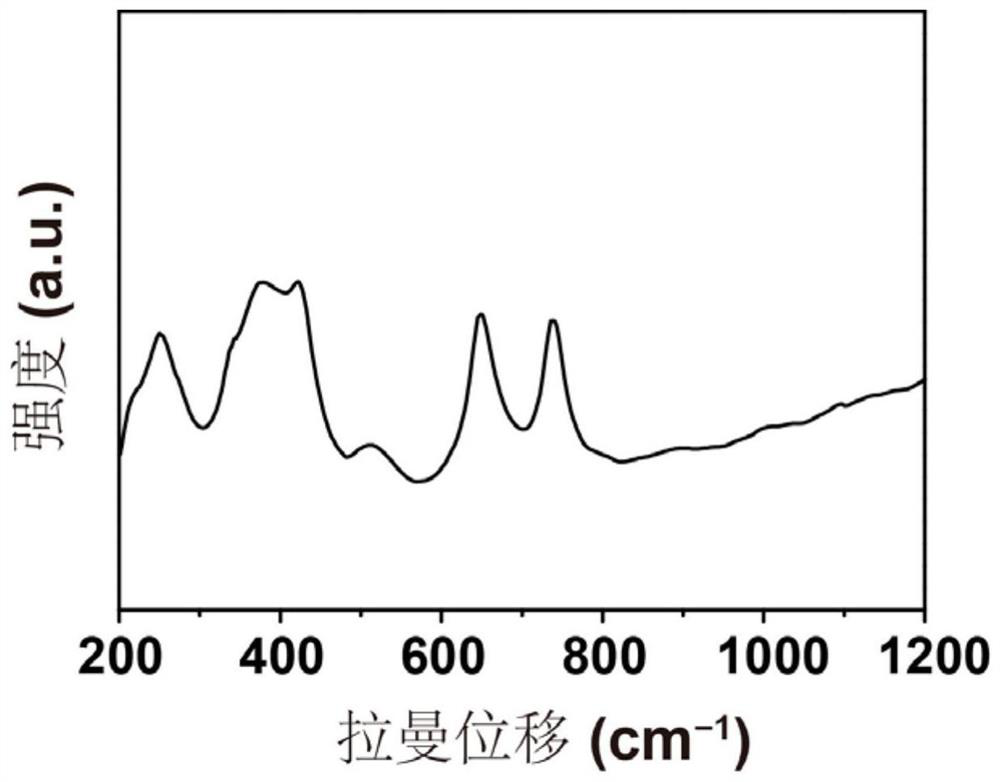

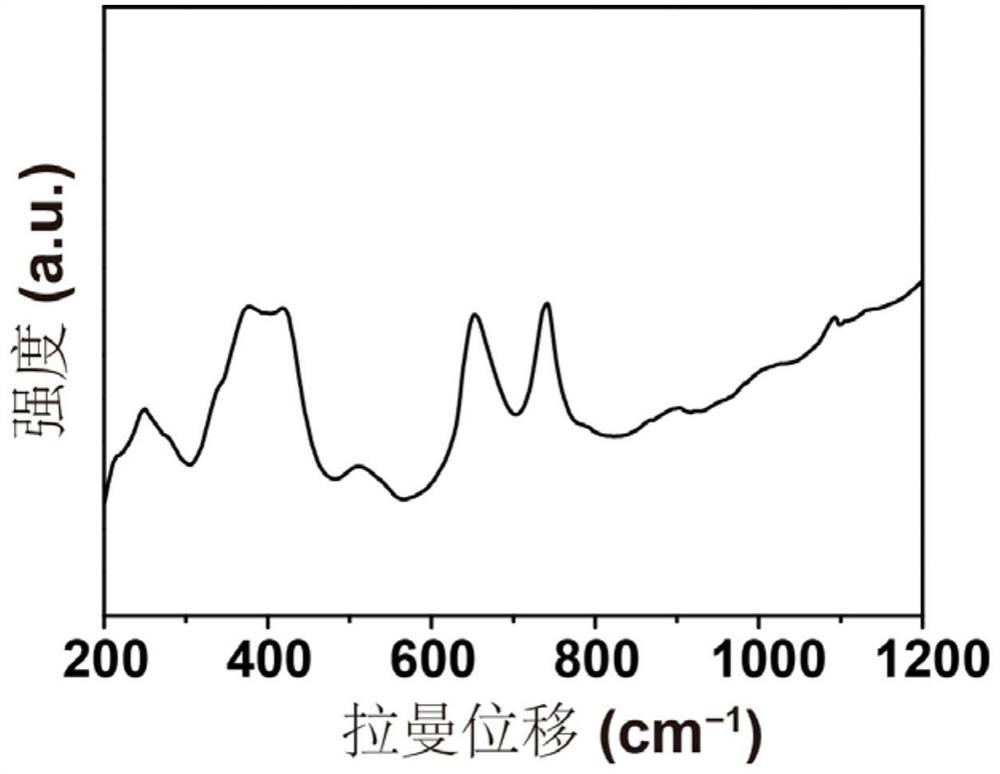

[0040] The treated LLZTO ceramic sheet is detected by Raman spectroscopy, and the obtained garnet-type solid electrolyte does not contain LiCO 3 . The wettability was observed in contact with molten metal lithium, and it was found that metal lithium could spread evenly on the modified surface.

[0041] 2. Assemble the full battery

[0042] Preparation of lithium iron phosphate cathode material: mix lithium iron phosphate, conductive carbon black, and polyvinylidene chloride at a mass ratio of 8:1:1, then add N-methylpyrrolidone to make a uniform slurry, and evenly coat it on aluminum foil On the...

Embodiment 2

[0045] Other steps are the same as in Example 1, the difference is that ammonium fluoride is replaced by ammonium chloride, and the obtained garnet-type solid electrolyte does not contain LiCO after detection by Raman spectroscopy. 3 .

Embodiment 3

[0047] Other steps are the same as in Example 1, the difference is that ammonium fluoride is replaced by ammonium bromide, and after Raman spectroscopy detection, the obtained garnet-type solid electrolyte does not contain LiCO 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com