Application of a functionalized carbon dot in lithium battery electrolyte

An electrolyte and lithium battery technology, applied in secondary batteries, secondary battery repair/maintenance, circuits, etc., can solve problems such as excessive charging current, lithium dendrite growth, battery short circuit, etc., to inhibit growth and improve Effect of safety and stability, excellent electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

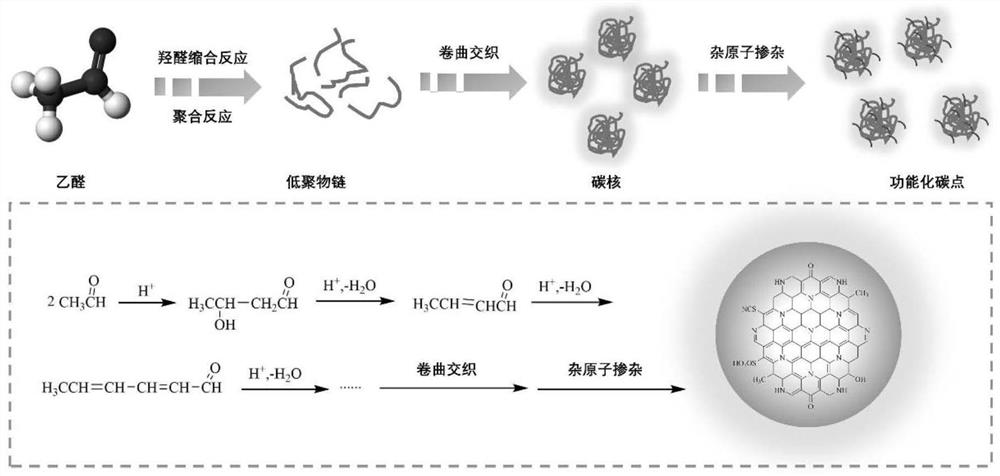

[0031] Example 1 Preparation of nitrogen and sulfur co-doping functionalized carbon dots

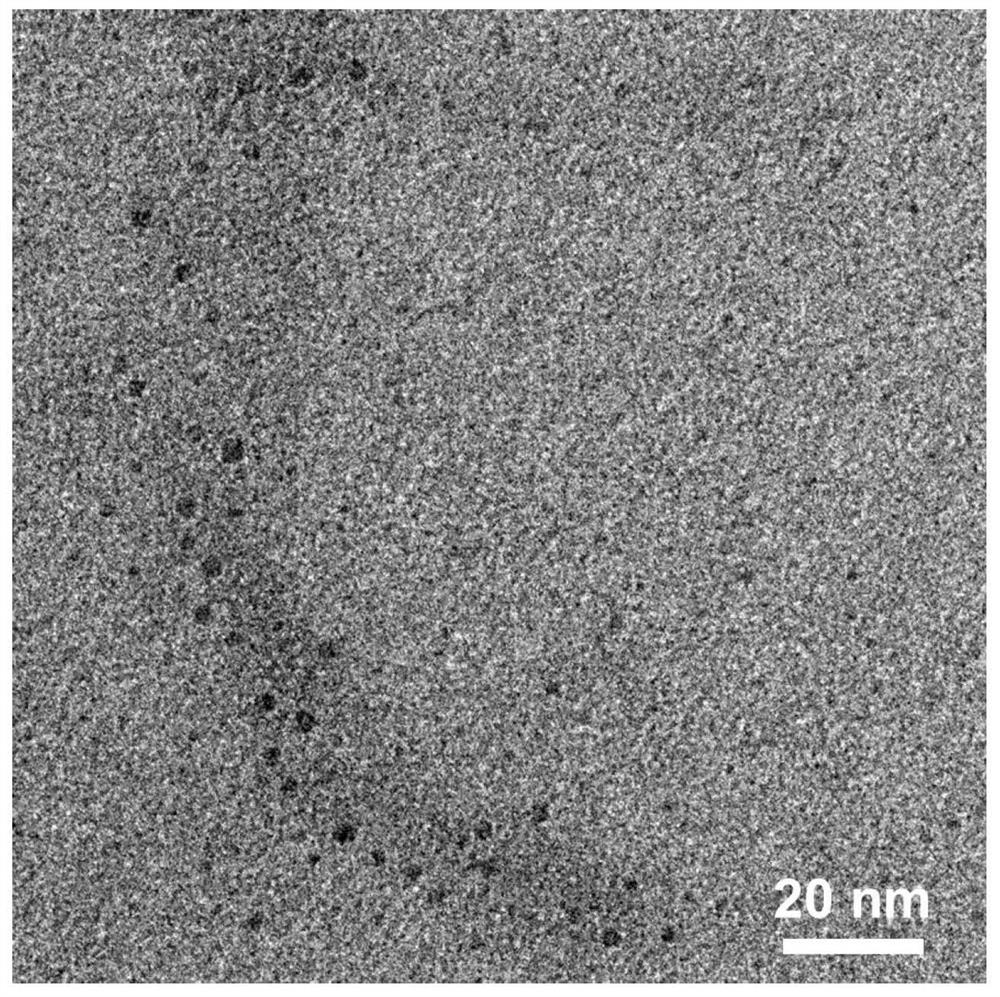

[0032] Weigh 4.0 g of thiourea and 40 mL of acetaldehyde (35 wt %) into a beaker, ultrasonically treat for 1 h to completely dissolve thiourea, and add 200 μL of concentrated sulfuric acid as a catalyst. The above mixture was transferred to a 100 mL hydrothermal reactor and heated at 180 °C for 6 h. After the reaction was completed, it was naturally cooled to room temperature, and the resulting brown viscous material was transferred to 2 L of deionized water, and sonicated continuously until the product was uniformly dispersed. The filter cake (ie, carbon dots) was collected by filtration through a microporous membrane (pore size was 0.22 μm), and then the carbon dots were washed with deionized water and suction filtered for several times to remove impurities. After drying in an oven at 60°C for 12 hours, nitrogen and sulfur co-doped functionalized carbon dot powders were collected.

...

Embodiment 2

[0036] The preparation of embodiment 2 electrolyte

[0037] S1. Under an inert atmosphere, the organic solvent 1,3-dioxolane (DOL) / ethylene glycol dimethyl ether (DME) is mixed in a volume ratio of 1:1 to prepare an electrolyte solvent;

[0038] S2. In an inert atmosphere, the functionalized carbon dot powder prepared in Example 1 and the lithium salt lithium bis-trifluoromethylsulfonimide (LiTFSI) were dissolved in the solvent prepared in step S1, and 2wt% LiNO was added. 3 , stir evenly, and prepare an electrolyte; wherein, the concentration of LiTFSI is 1.0 mol / L, and the concentration of functionalized carbon dots is 0.3 mg / mL.

[0039] Electrochemical performance test:

[0040](1) The lithium metal sheet was used as the negative electrode, the copper foil was used as the positive electrode, and 40 μL of the electrolyte prepared above was dropped on both sides of the PE separator to assemble the Li / Cu half-cell. At a current density of 1 mA cm -2 , the discharge capacit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com