Lithium-sulfur secondary battery with high cycling stability and high coulombic efficiency

A lithium-sulfur secondary battery, cycle stability technology, applied in the direction of secondary batteries, secondary battery repair/maintenance, lithium batteries, etc., can solve the problems of positive electrode capacity attenuation, destruction of solid-phase reaction mechanism, etc., to achieve inhibition of dissolution, Improve the utilization rate and the capacity retention rate of lithium-sulfur batteries, and alleviate the effect of volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The lithium salt is lithium bisfluorosulfonimide, the ether compound is ethylene glycol dimethyl ether, and the compound containing a cyclic C=O structure is ethylene carbonate. Wherein, the concentration of lithium bisfluorosulfonyl imide is 1 mol / L, and ethylene carbonate accounts for 15 wt% of the total mass of ethylene glycol dimethyl ether and ethylene carbonate.

[0044] Use the above electrolyte, metal lithium negative electrode, vulcanized polyacrylonitrile positive electrode, and Celgard2400 diaphragm to assemble a lithium-sulfur battery. The specific operations are as follows:

[0045] Mix vulcanized polyacrylonitrile, carbon nanotubes and polyvinylidene fluoride uniformly in N-methylpyrrolidone at a mass ratio of 8:1:1 to obtain a slurry with a concentration of 30%;

[0046] The slurry was uniformly coated on carbon-coated aluminum foil, dried at 60°C for 12 hours, and then cut into discs with a diameter of 11mm for button batteries or pole pieces with a shap...

Embodiment 2~4

[0053] The assembly of the battery is similar to that of Example 1, the only difference being that the mass fraction of ethylene carbonate in the electrolyte is 5%, 10%, and 20%.

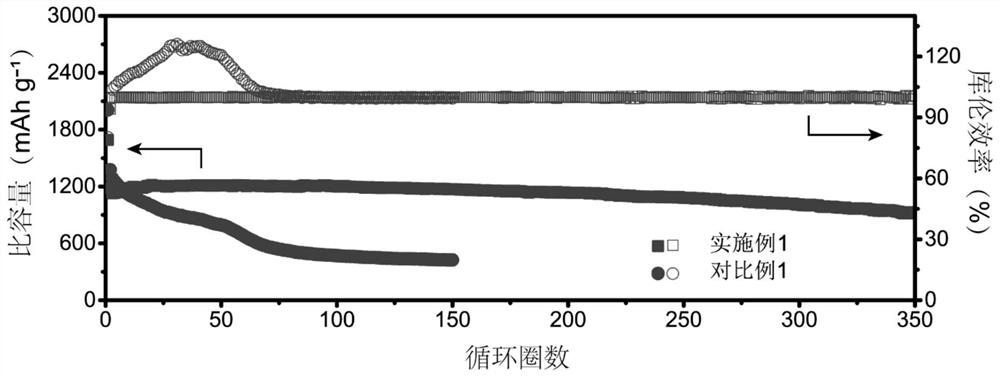

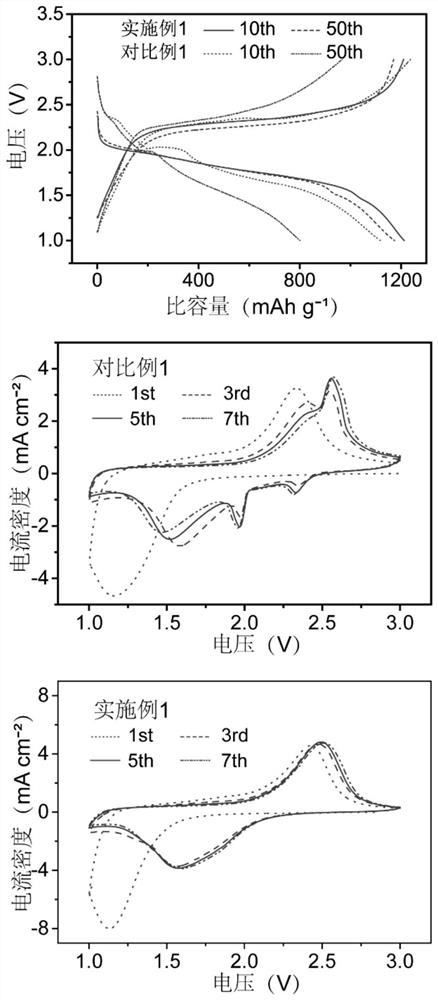

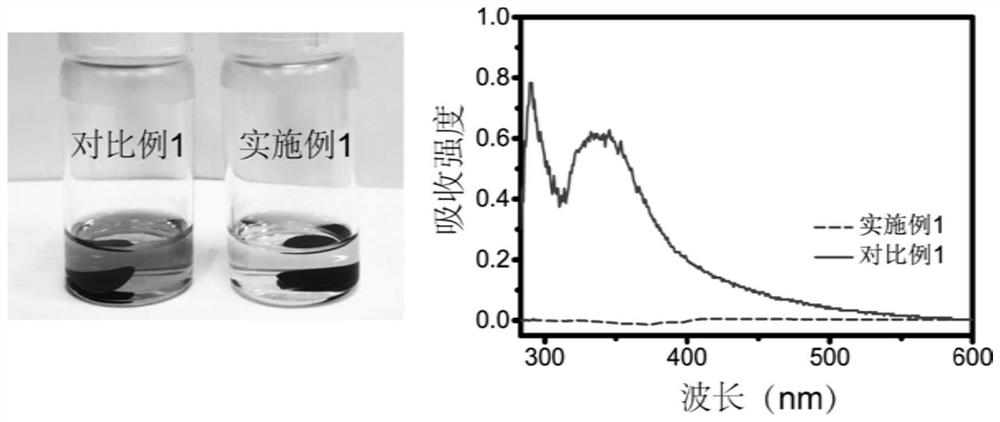

[0054] Under the condition of charge and discharge rate of 0.5C, the cycle performance test was carried out on the batteries respectively assembled with the electrolyte solutions provided in Examples 1 to 4, and the charge and discharge voltage curves were as follows: Figure 4 As shown in the figure, the mass fraction of ethylene carbonate is 5% and is recorded as EC05, and the mass fraction of ethylene carbonate is 10% and is recorded as EC10, and the mass fraction of ethylene carbonate is 15% and is recorded as EC15, and the mass fraction of ethylene carbonate is recorded as EC15. A score of 20% is recorded as EC20 (the same below). The charging and discharging voltage curves of the batteries assembled in each embodiment all present the characteristics of a single platform, indicating the effecti...

Embodiment 5

[0058] The assembly of the battery is similar to that of Example 1, the only difference being that the lithium salt in the electrolyte is lithium bistrifluoromethanesulfonylimide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com