Mung bean and peanut beancurds capable of clearing heat and removing toxicity and production technology of mung bean and peanut beancurds capable of clearing heat and removing toxicity

A technology of heat-clearing and detoxifying, peanut tofu, applied in the field of food processing, can solve the problems of single taste, greasy food, troublesome eating tofu, etc., and achieve the effect of simple and practical process operation, ingenious conception and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1) Making raw materials:

[0035] Peanut: Weihua No. 20;

[0036] Soybean: Weidou No. 9;

[0037] Mung beans: Weilu No. 9;

[0038] Coagulant: food grade calcium sulfate; food grade magnesium chloride; food grade GDL (glucono-delta-lactone).

[0039] 2) Use the instrument:

[0040] Electronic balance, electric heating pot, soybean milk juicer, constant temperature water bath, tofu mold, etc.

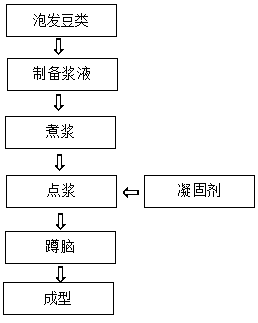

[0041] 3) The production process of mung bean heat-clearing and detoxifying peanut tofu:

[0042] Choose mung beans, soybeans, and peanuts with fresh color, full grain, and no rot, remove impurities, and wash with water.

[0043] Soak beans: clean mung beans, peanuts, soybeans and water at a ratio of 1:6, soak in water at 12.5°C for 13 hours in winter, 9 hours in water at 17.5°C in spring and autumn, and at 27.5°C in summer After soaking for 7 hours, the surface of the soaked soybeans and mung beans is plump, the skin is round, and the section of soybeans has no hard core; t...

Embodiment 2

[0097]1) Soak beans: Soak clean mung beans, peanuts, and soybeans for 12 hours in winter at a water temperature of 15°C, in spring and autumn for 8 hours at a water temperature of 20°C, and in summer for 6 hours at a water temperature of 30°C. The mass ratio of such dry matter as 4:1;

[0098] 2) Preparation of slurry: Put the soaked mung beans, peanuts, and soybeans into a refiner in a mass ratio of 1:1:3 for refining. The mass ratio of water to beans and mung beans in the refining is 6:1. Refining for 2 times and mixing evenly, and filtering after each refining to obtain slurry;

[0099] 3) Cooking: Put the filtered slurry into an ordinary pot or a sealed cooking tank for cooking. The ordinary pot cooking method adopts the "three ups and three downs boiling method" to cook for about 8 minutes. When using a sealed cooking tank for cooking , the temperature is 95°C, cook for 5 minutes;

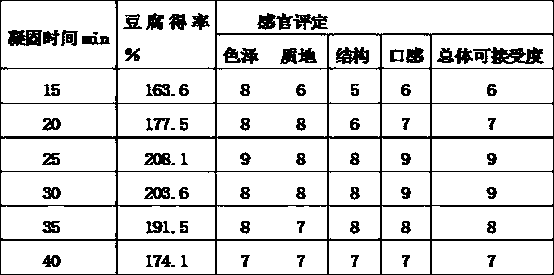

[0100] 4) Sorting: cool down the boiled slurry, lower the temperature to 80°C, add 2‰ ma...

Embodiment 3

[0104] 1) Soak beans: Soak clean mung beans, peanuts, and soybeans for 13 hours in winter at a water temperature of 12.5°C, in spring and autumn for 9 hours at a water temperature of 17.5°C, and in summer for 7 hours at a water temperature of 27.5°C. The mass ratio of dry matter such as class is 5:1;

[0105] 2) Preparation of slurry: Put the soaked mung beans, peanuts, and soybeans into a refiner in a mass ratio of 1:3:6 for refining. The mass ratio of water to beans and mung beans in the refining is 6:1. Refining for 2 times and mixing evenly, and filtering after each refining to obtain slurry;

[0106] 3) Cooking: Put the filtered slurry into a common pot or a sealed cooking tank for cooking. The common pot cooking method adopts the "three ups and three downs boiling method" to cook for about 10 minutes. When using a sealed cooking tank for cooking , the temperature is 100°C, cook for 8 minutes;

[0107] 4) Point slurry: cool down the boiled slurry, lower the temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com