A kind of mild foam amino acid cleansing cream and preparation method thereof

An amino acid and cleansing cream technology, which is applied in the field of skin care products, can solve the problems of insufficient amount of foam and can not play a cleaning effect, etc., and achieves the effects of improving appearance and stability, enriching foam and simple and easy preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

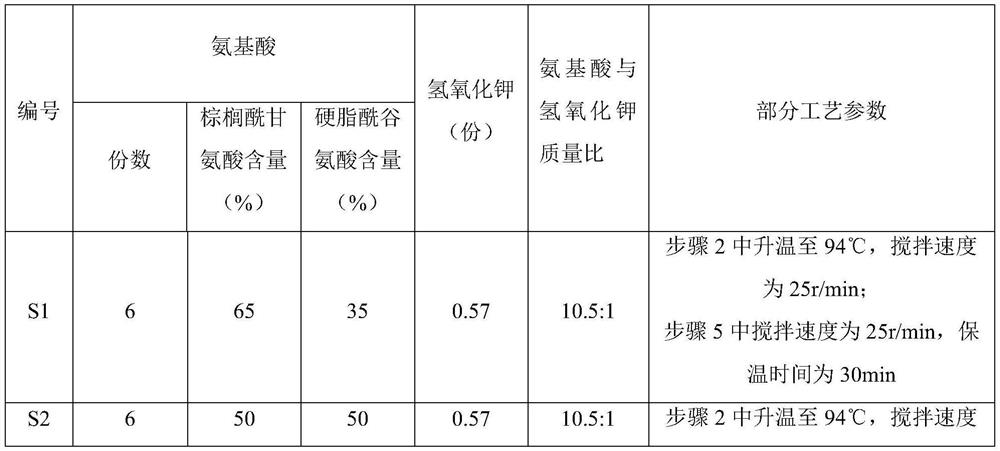

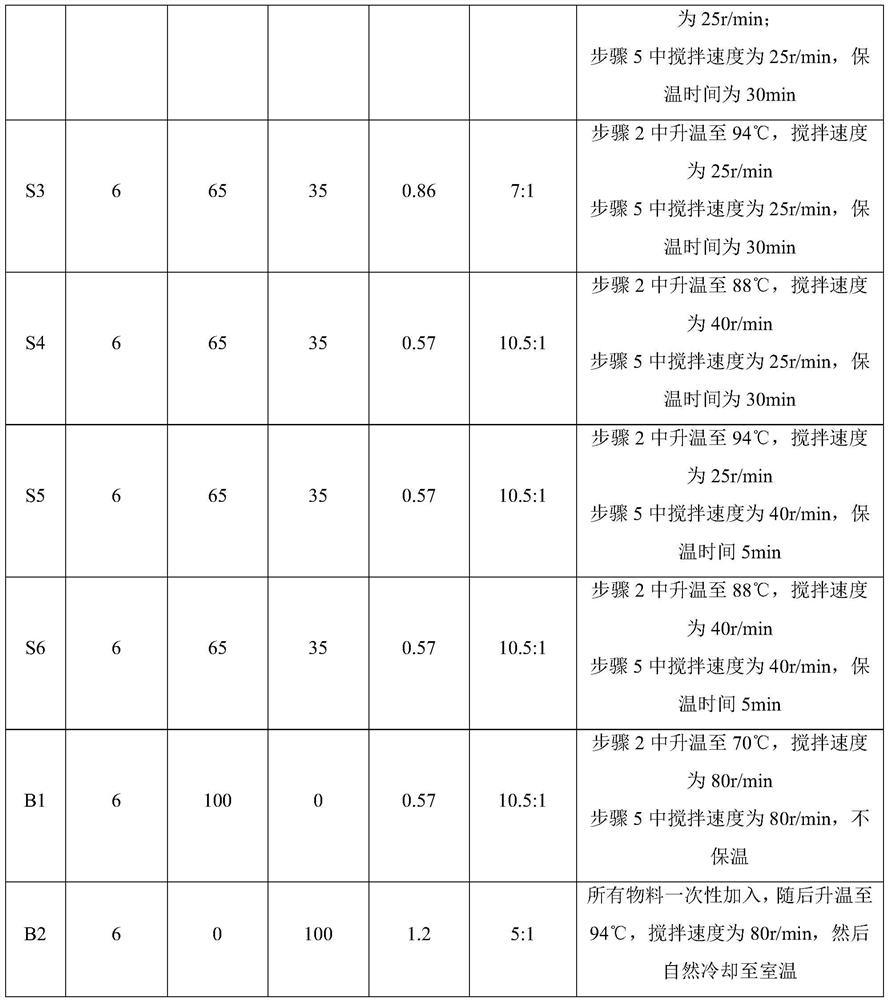

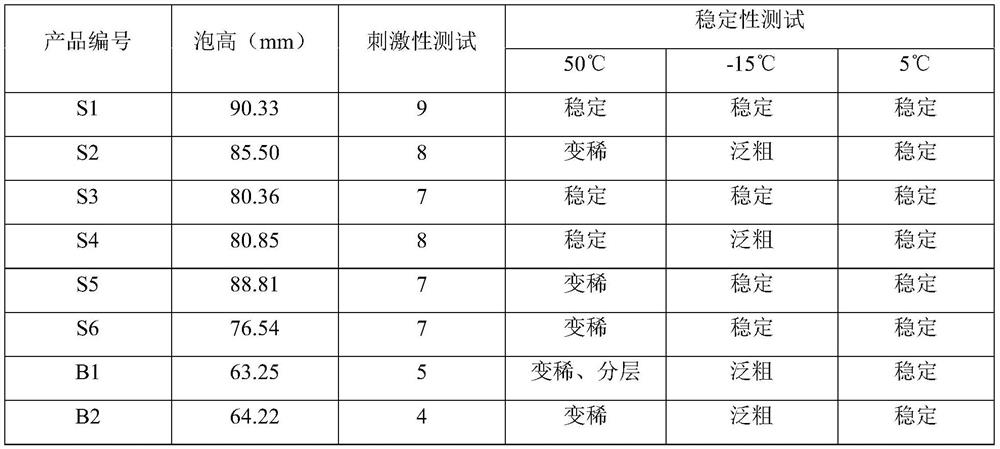

Embodiment 1

[0031] 1. In terms of parts by mass, get 16 parts of glycerin, 0.1 part of polyethylene glycol-14M, 0.2 part of methylparaben, 10 parts of sorbitol, 6 parts of amino acids (specifically 65 wt% of palmitoyl glycine and 35 wt % of stearin acylglutamic acid), 25 parts of water, and stir evenly at a low speed at a stirring speed of 25r / min to obtain solution A;

[0032] 2. Slowly add 7.5 parts of sodium cocoyl glycinate and 6 parts of cocamidopropyl betaine to solution A, stir evenly at a low speed of 25r / min, then slowly heat up to 94°C, and then heat up to 94°C Add the potassium hydroxide aqueous solution mixed in advance under the temperature insulation, this potassium hydroxide aqueous solution is 0.63 parts of industrial potassium hydroxide 90% (the content of potassium hydroxide is 90%, then potassium hydroxide is 0.57 parts) dissolves in 1.09 parts of water Prepared, continue to stir at a low speed for 60min at a stirring speed of 25r / min, until there are no particles in th...

Embodiment 2

[0040] 1. In terms of parts by mass, get 16 parts of glycerin, 0.1 part of polyethylene glycol-14M, 0.2 part of methylparaben, 10 parts of sorbitol, 6 parts of amino acids (specifically 50wt% of palmitoyl glycine and 50wt% of stearin acylglutamic acid), 25 parts of water, and stir evenly at a low speed at a stirring speed of 25r / min to obtain solution A;

[0041] 2. Slowly add 7.5 parts of sodium cocoyl glycinate and 6 parts of cocamidopropyl betaine to solution A, stir evenly at a low speed of 25r / min, then slowly heat up to 94°C, and then heat up to 94°C Add the potassium hydroxide aqueous solution mixed in advance under the temperature insulation, this potassium hydroxide aqueous solution is 0.63 parts of industrial potassium hydroxide 90% (the content of potassium hydroxide is 90%, then potassium hydroxide is 0.57 parts) dissolves in 1.09 parts of water Prepared, continue to stir at a low speed for 60min at a stirring speed of 25r / min, until there are no particles in the s...

Embodiment 3

[0049] 1. In terms of parts by mass, get 16 parts of glycerin, 0.1 part of polyethylene glycol-14M, 0.2 part of methylparaben, 10 parts of sorbitol, 6 parts of amino acids (specifically 65 wt% of palmitoyl glycine and 35 wt % of stearin acylglutamic acid), 25 parts of water, and stir evenly at a low speed at a stirring speed of 25r / min to obtain solution A;

[0050] 2. Slowly add 7.5 parts of sodium cocoyl glycinate and 6 parts of cocamidopropyl betaine to solution A, stir evenly at a low speed of 25r / min, then slowly heat up to 94°C, and then heat up to 94°C Add the potassium hydroxide aqueous solution mixed in advance under the temperature insulation, this potassium hydroxide aqueous solution is 0.96 parts of industrial potassium hydroxide 90% (the content of potassium hydroxide is 90%, then potassium hydroxide is 0.86 parts) dissolves in 1.09 parts of water Prepared, continue to stir at a low speed for 60min at a stirring speed of 25r / min, until there are no particles in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com