Production technology of gelatin hard empty capsule

A technology of hollow capsules and production process, which is applied in the direction of capsule transportation, medical preparations of non-active ingredients, inorganic non-effective ingredients, etc. It can solve the problems of low-temperature brittleness, low drying efficiency of dipping glue, and many production processes, etc., and achieve good results. Workability and viscosity, good biodegradability, and the effect of avoiding low temperature embrittlement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

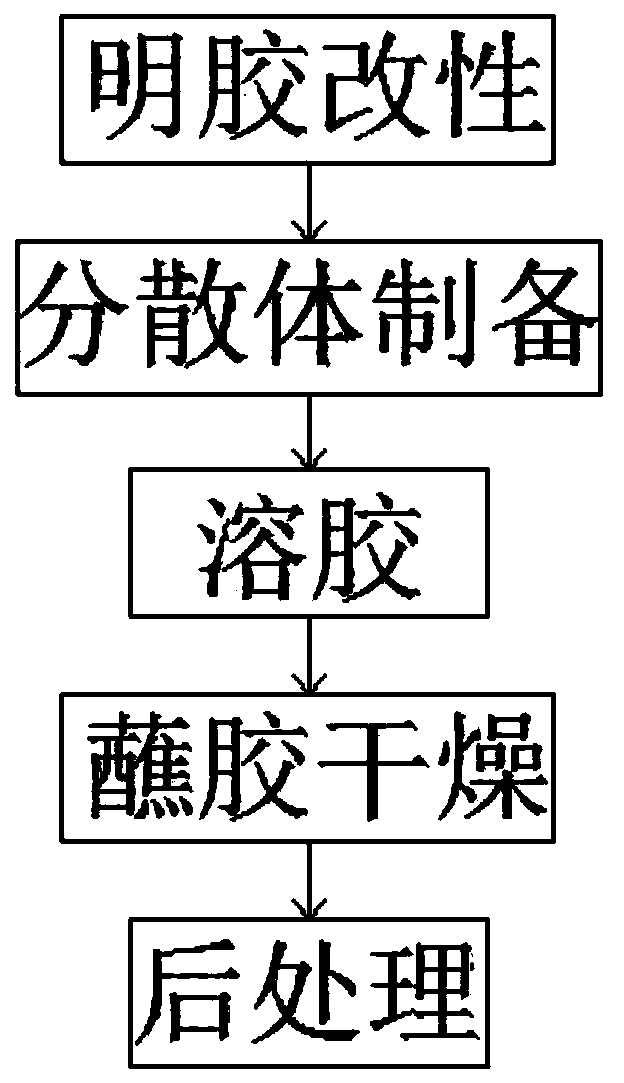

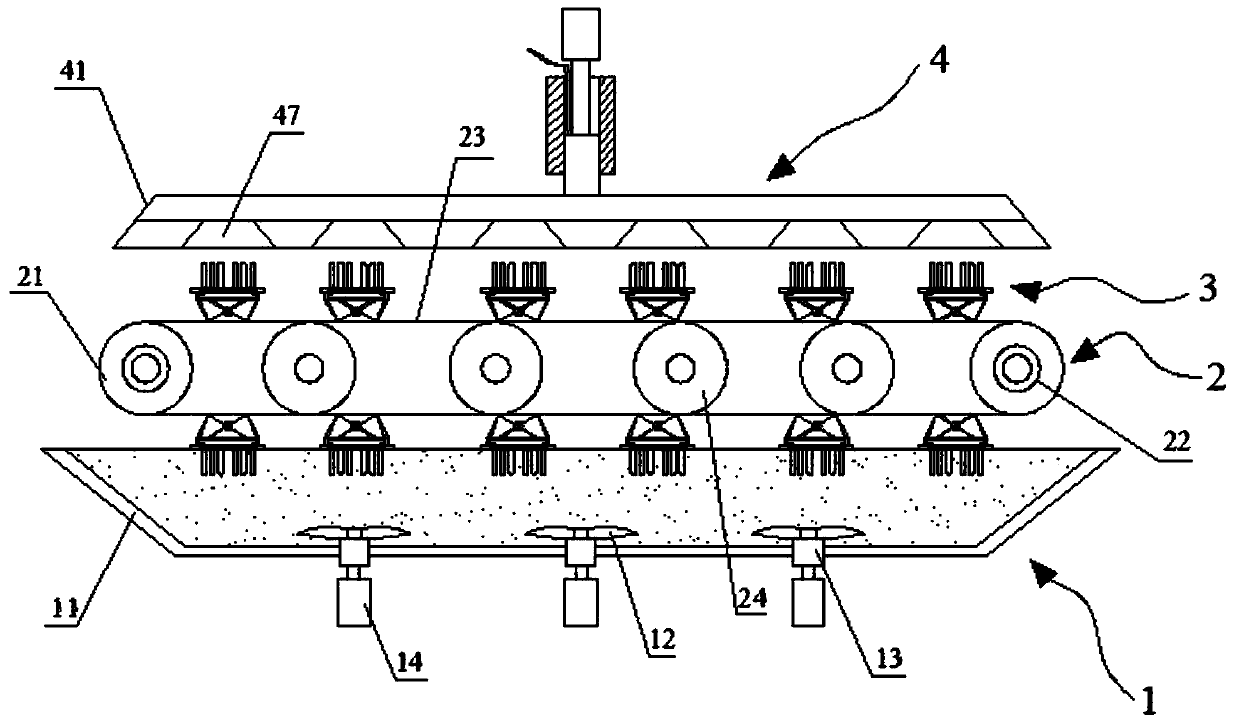

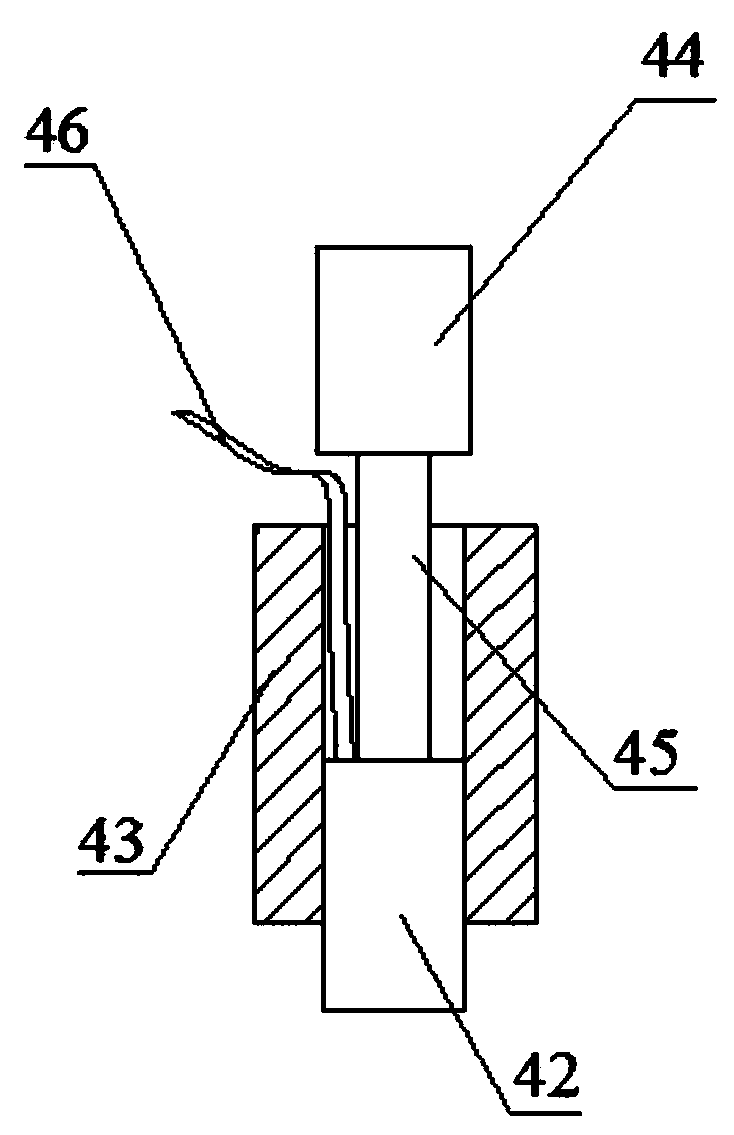

[0035] refer to Figure 1-4 As shown, the present embodiment provides a kind of production technology of gelatin hard hollow capsule, comprises the following steps:

[0036] S1. Gelatin modification: In parts by weight, weigh 4 parts of gelatin, add 45 parts of deionized water, stir and heat up to 60°C, keep warm and stir until the gelatin is completely dissolved, and filter and decolorize with activated carbon to obtain a gelatin solution; take 14 parts of phenylalanine Add 2wt% hydrochloric acid solution, heat at 38°C for 25min to obtain the hydrochloric acid solution of phenylalanine; add 10.8mL of 6wt% carbodiimide aqueous solution to the gelatin solution, stir evenly at room temperature, slowly add Hydrochloric acid solution 75mL, continue to stir for 26min to obtain the cross-linked reactant; pour the cross-linked reactant into a plastic mold, keep the thickness of the formed liquid layer less than 1cm, and dry aseptically at 45°C for 22 hours to obtain the crude modifie...

Embodiment 2

[0045] refer to Figure 1-4 As shown, the present embodiment provides a kind of production technology of gelatin hard hollow capsule, comprises the following steps:

[0046] S1. Gelatin modification: in parts by weight, weigh 5 parts of gelatin, add 55 parts of deionized water, stir and heat up to 62°C, heat and stir until the gelatin is completely dissolved, and filter and decolorize with activated carbon to obtain a gelatin solution; take phenylalanine 18 part, add 2wt% hydrochloric acid solution, heat at 40°C for 25min to obtain the hydrochloric acid solution of phenylalanine; Hydrochloric acid solution 76mL, continue to stir for 25min to obtain the cross-linked reactant; pour the cross-linked reactant into a plastic mold, keep the thickness of the formed liquid layer less than 1cm, and dry aseptically at 43°C for 23 hours to obtain the crude modified gelatin; Grinding, ball milling and aseptic drying to obtain the modified gelatin compound.

[0047] The crude modified ge...

Embodiment 3

[0055] refer to Figure 1-4 As shown, the present embodiment provides a kind of production technology of gelatin hard hollow capsule, comprises the following steps:

[0056] S1. Gelatin modification: in parts by weight, weigh 6 parts of gelatin, add 55 parts of deionized water, stir and heat up to 61°C, heat and stir until the gelatin is completely dissolved, and filter and decolorize with activated carbon to obtain a gelatin solution; take phenylalanine 17 Add 2wt% hydrochloric acid solution, heat at 40°C for 25min to obtain the hydrochloric acid solution of phenylalanine; add 12mL of 6wt% carbodiimide aqueous solution to the gelatin solution, stir evenly at room temperature, slowly add the hydrochloric acid of phenylalanine Solution 80mL, continue to stir for 30min to obtain the cross-linked reactant; pour the cross-linked reactant into a plastic mold, keep the thickness of the formed liquid layer less than 1cm, and dry aseptically at 45°C for 24 hours to obtain the crude mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com