Epoxy resin-based composite wave-absorbing material, preparation method and applications thereof

A composite wave absorbing material and epoxy resin matrix technology, applied in the field of wave absorbing materials, can solve problems such as unfavorable large-scale production, complex preparation process, complex structure, etc., and achieve strong practical value, simple preparation method, and excellent wave absorbing performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

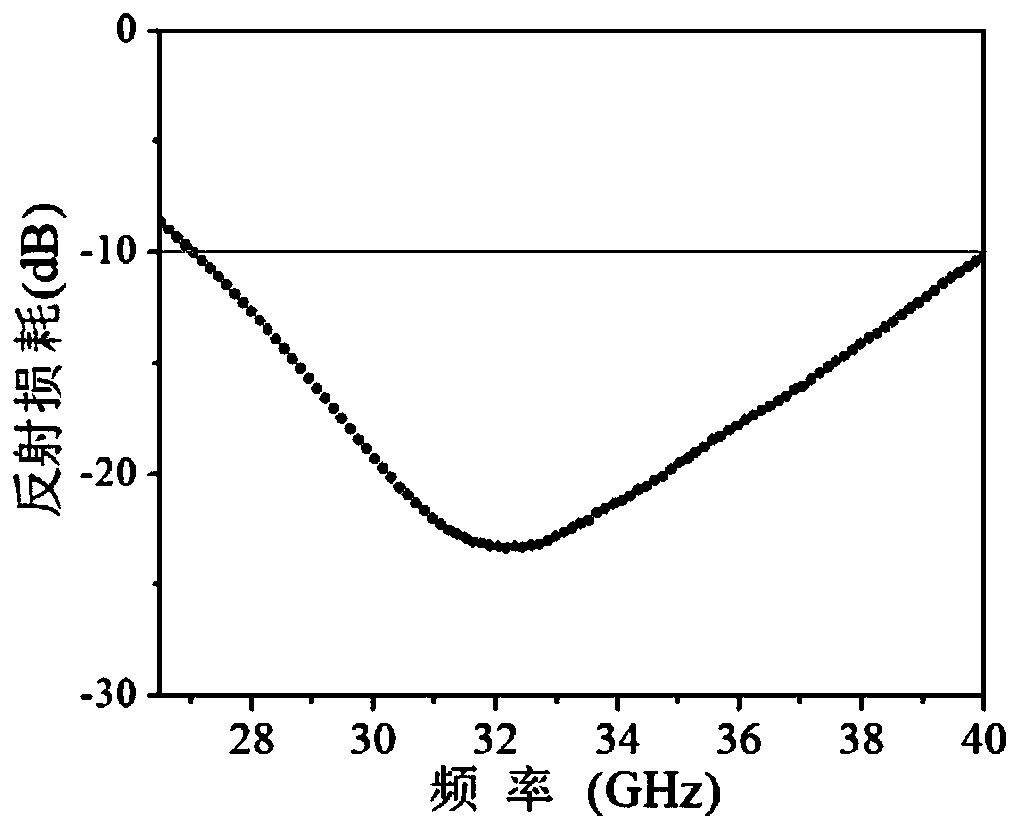

Embodiment 1

[0042] This embodiment provides an epoxy resin-based composite wave-absorbing material, which is prepared according to the following steps:

[0043] (1) In situ preparation of BaNb by the improved sol-gel method 0.65 Fe 11.35 o 19 Precursors, specifically: Weigh the corresponding mass of analytically pure barium acetate, ferric nitrate, and niobium oxalate according to the molar ratio of the formula, put them in three beakers, dissolve them with deionized water, and stir them magnetically for about 30~ 60 minutes;

[0044] Mix the solutions obtained above, add an appropriate amount of deionized water, and stir magnetically for about 2 to 3 hours to obtain a transparent sol that is BaNb 0.65 Fe 11.35 o 19 Precursor;

[0045] BaNb 0.65 Fe 11.35 o 19 The precursor was placed in a muffle furnace at 200°C for 1 hour, then raised to 400°C for a further 1 hour, and then sintered in a muffle furnace at 1350°C for 6 hours to obtain BMFO wave absorbing agent powder BaNb 0.65 F...

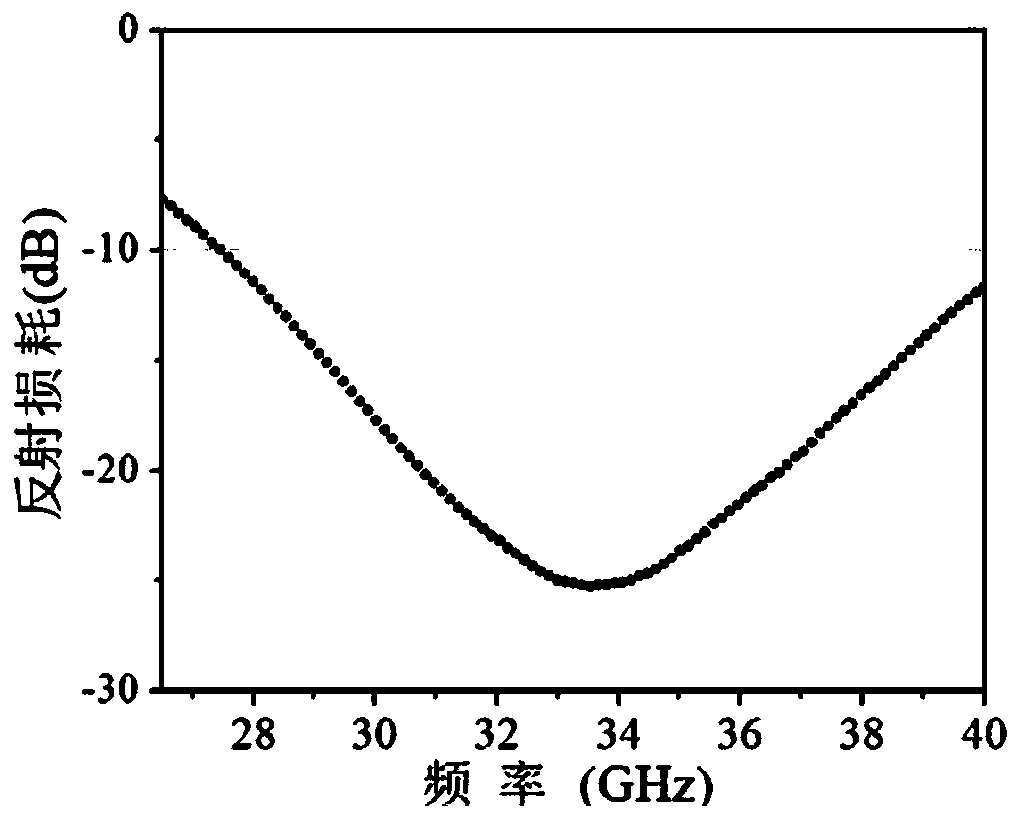

Embodiment 2

[0050] This embodiment provides an epoxy resin-based composite wave-absorbing material, which is prepared according to the following steps:

[0051] (1) In situ preparation of BaNb by the improved sol-gel method 0.63 Fe 11.37 o 19 Precursors, specifically: Weigh the corresponding mass of analytically pure barium acetate, ferric nitrate, and niobium oxalate according to the molar ratio of the formula, put them in three beakers, dissolve them with deionized water, and stir them magnetically for about 30~ 60 minutes;

[0052] Mix the solutions obtained above, add an appropriate amount of deionized water, and stir magnetically for about 2 to 3 hours to obtain a transparent sol that is BaNb 0.63 Fe 11.37 o 19 Precursor;

[0053] BaNb 0.63 Fe 11.37 o 19 The precursor was placed in a muffle furnace at 210°C for 2 hours, then raised to 450°C for a further 2 hours, and then sintered in a muffle furnace at 1400°C for 5 hours to obtain BMFO absorber powder BaNb 0.63 Fe 11.37 o...

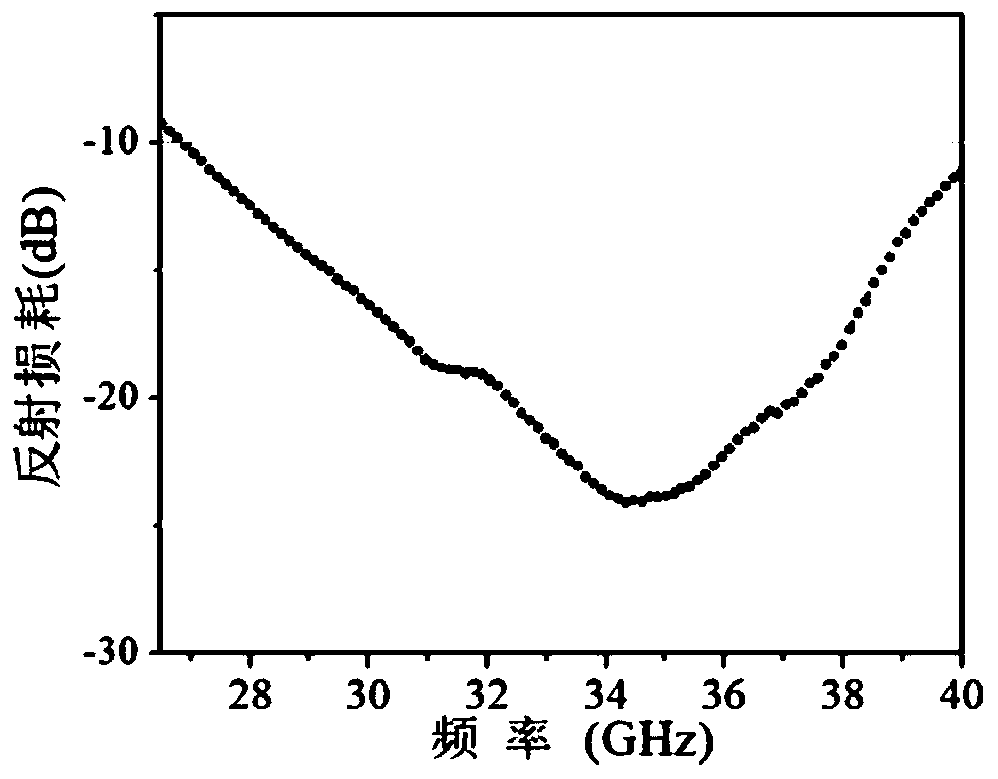

Embodiment 3

[0058] This embodiment provides an epoxy resin-based composite wave-absorbing material, which is prepared according to the following steps:

[0059] (1) In situ preparation of BaNb by the improved sol-gel method 0.62 Fe 11.38 o 19 Precursors, specifically: Weigh the corresponding mass of analytically pure barium acetate, ferric nitrate, and niobium oxalate according to the molar ratio of the formula, put them in three beakers, dissolve them with deionized water, and stir them magnetically for about 30~ 60 minutes;

[0060] Mix the solutions obtained above, add an appropriate amount of deionized water, and stir magnetically for about 2 to 3 hours to obtain a transparent sol that is BaNb 0.62 Fe 11.38 o 19 Precursor;

[0061] BaNb 0.62 Fe 11.38 o 19 The precursor was placed in a muffle furnace at 240°C for 2.5 hours, then raised to 480°C for a further 2.5 hours, and then sintered in a muffle furnace at 1420°C for 4 hours to obtain BMFO absorber powder BaNb 0.62 Fe 11....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com