Method for supercritical carbon dioxide fluid extraction of sterol-rich sea-buckthorn seed oil

A technology of carbon dioxide and sea buckthorn seed oil, which is used in the production of fat oil/fat and fat production, can solve the problems of low penetration and diffusion speed, complicated extraction process, and high equipment cost, and achieves improved extraction yield, simple and significant extraction process. economic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

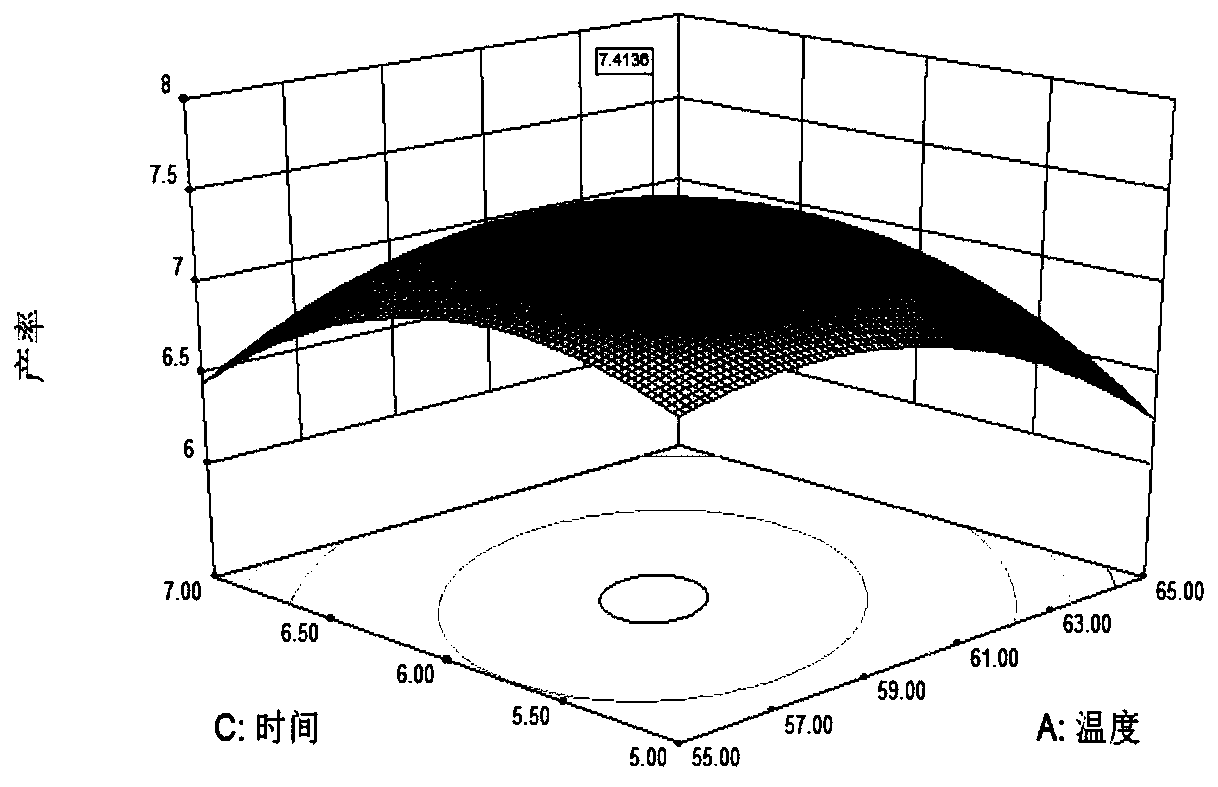

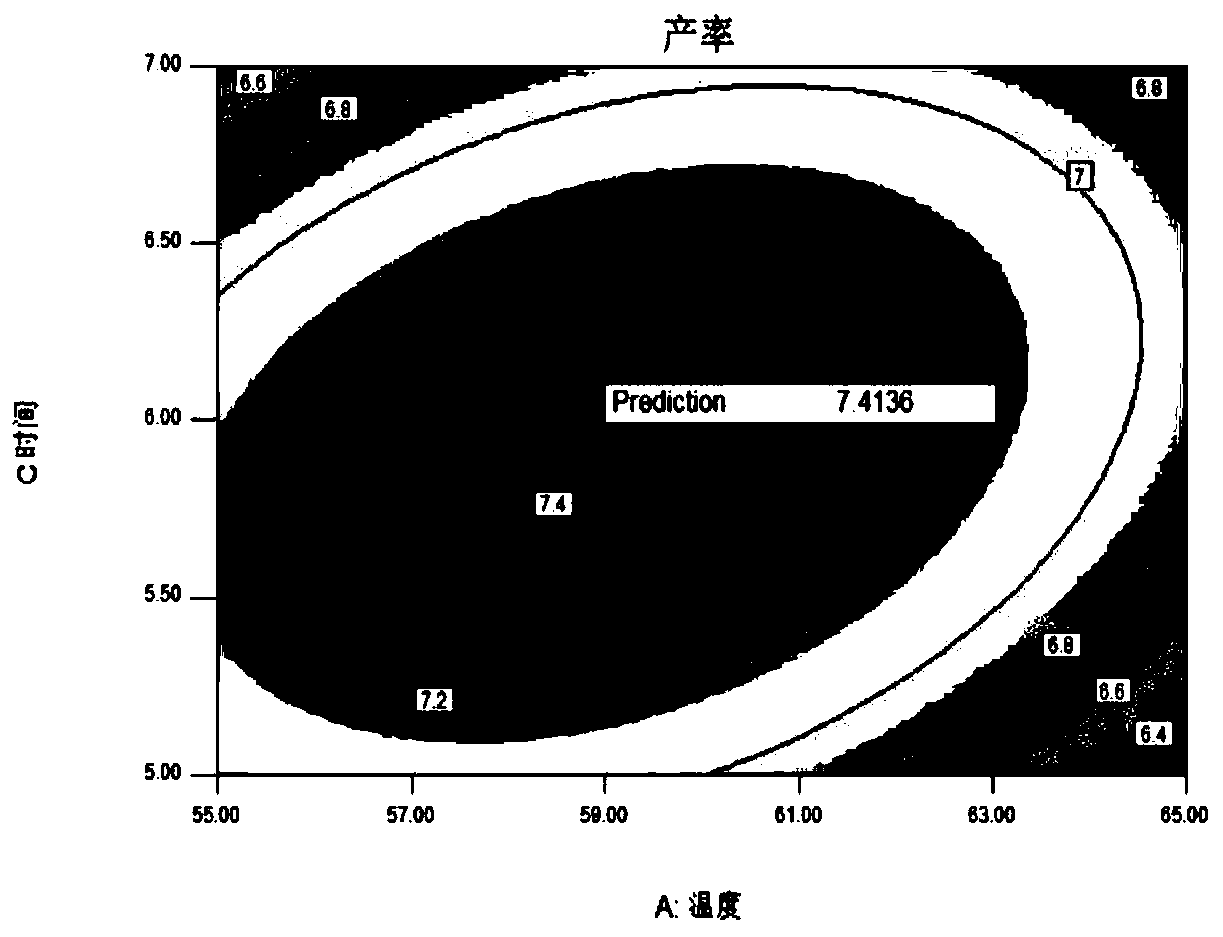

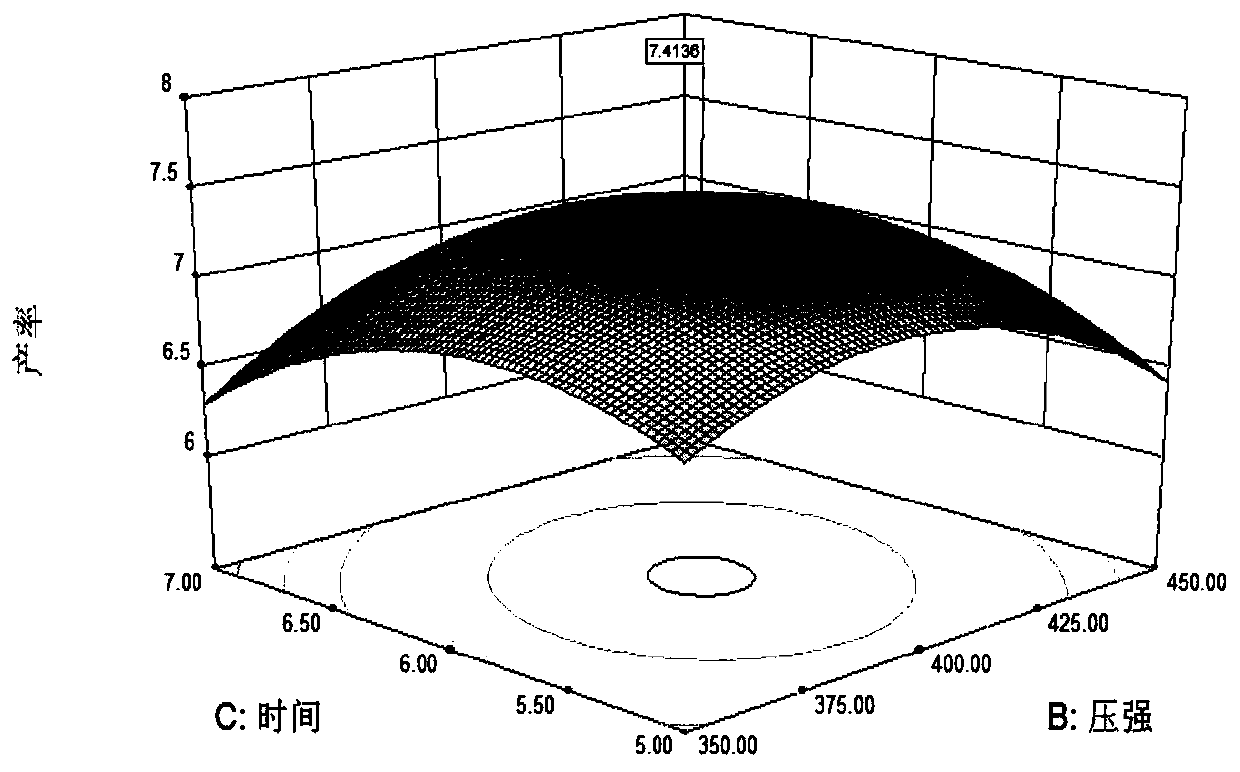

Image

Examples

Embodiment 1

[0025] A method for supercritical carbon dioxide fluid extraction of seabuckthorn seed oil rich in sterols, comprising the steps of:

[0026] Step 1: drying seabuckthorn seeds to constant weight to obtain dry samples of seabuckthorn seeds;

[0027] Step 2: crush the dried seabuckthorn seeds with a high-speed pulverizer to obtain crushed seabuckthorn seeds;

[0028] Step 3: Sieve the crushed seabuckthorn seed sample with a mesh sieve with a mesh number of 40 mesh and an aperture of 0.425 mm, and remove impurities larger than the aperture of 0.425 mm with a mesh sieve of 40 mesh to obtain a suitable seabuckthorn seed powder sample;

[0029] Step 4: Weigh 50g of seabuckthorn seed powder sample, and put 10mL of entrainer anhydrous ethanol into the extraction ax together;

[0030] Step 5: Perform supercritical carbon dioxide fluid extraction under conditions of an extraction temperature of 50°C, an extraction time of 5 hours, and an extraction pressure of 300 bar to obtain seabuck...

Embodiment 2

[0033] A method for supercritical carbon dioxide fluid extraction of seabuckthorn seed oil rich in sterols, comprising the steps of:

[0034] Step 1: drying seabuckthorn seeds to constant weight to obtain dry samples of seabuckthorn seeds;

[0035] Step 2: crush the dried seabuckthorn seeds with a high-speed pulverizer to obtain crushed seabuckthorn seeds;

[0036] Step 3: Sieve the crushed seabuckthorn seed sample with a mesh sieve with a mesh number of 60 mesh and an aperture of 0.25mm, and remove impurities smaller than 0.25mm with a mesh sieve of 60 mesh to obtain a suitable seabuckthorn seed powder sample;

[0037] Step 4: Weigh 50g of seabuckthorn seed powder sample, and put 10mL of entrainer anhydrous ethanol into the extraction ax together;

[0038] Step 5: Perform supercritical carbon dioxide fluid extraction under conditions of an extraction temperature of 60°C, an extraction time of 6 hours, and an extraction pressure of 400 bar to obtain seabuckthorn seed oil;

...

Embodiment 3

[0041] A method for supercritical carbon dioxide fluid extraction of seabuckthorn seed oil rich in sterols, comprising the steps of:

[0042] Step 1: drying seabuckthorn seeds to constant weight to obtain dry samples of seabuckthorn seeds;

[0043] Step 2: crush the dried seabuckthorn seeds with a high-speed pulverizer to obtain crushed seabuckthorn seeds;

[0044] Step 3: Sieve the crushed seabuckthorn seed sample with a mesh sieve with a mesh number of 40 mesh and an aperture of 0.425 mm, and remove impurities larger than the aperture of 0.425 mm with a mesh sieve of 40 mesh to obtain a suitable seabuckthorn seed powder sample;

[0045] Step 4: Weigh 50g of seabuckthorn seed powder sample, and put 10mL of entrainer anhydrous ethanol into the extraction ax together;

[0046] Step 5: Perform supercritical carbon dioxide fluid extraction under conditions of an extraction temperature of 70°C, an extraction time of 7 hours, and an extraction pressure of 500 bar to obtain seabuck...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com