A moisture-absorbing and dry textile fabric

A textile fabric, dry technology, applied in the field of textiles, can solve the problems that the fabric does not have the function of moisture absorption and perspiration, poor moisture permeability, easy to pilling, etc., and achieves the effect of improving the feeling of washing with water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

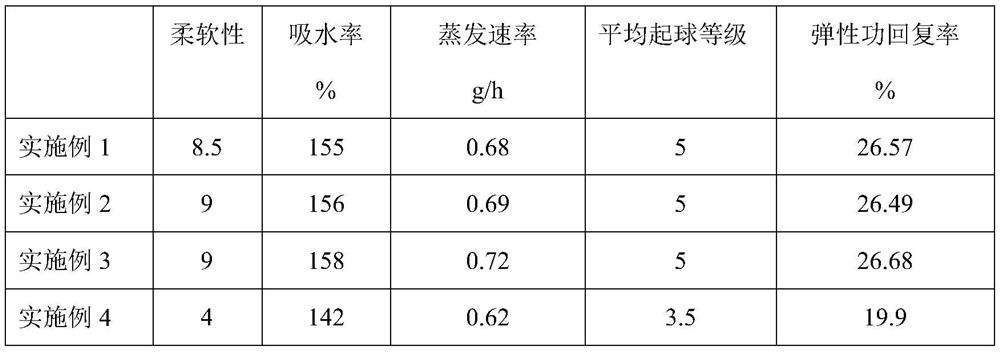

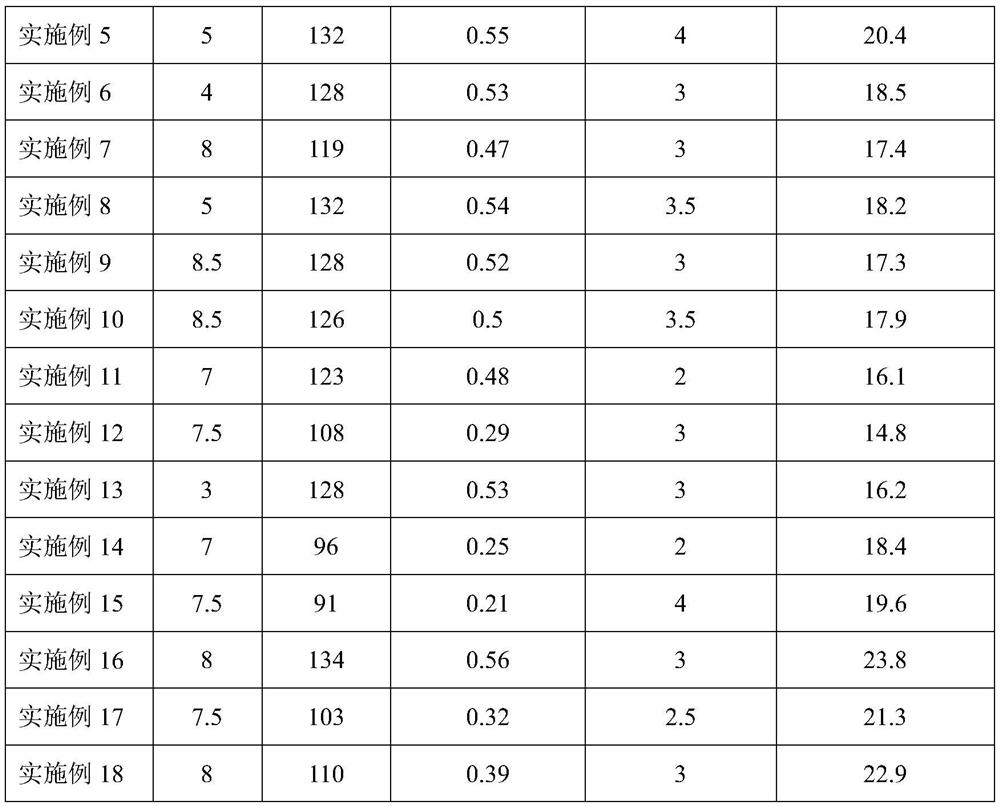

Examples

preparation example Construction

[0095] A second aspect of the present invention provides a method for preparing a moisture-absorbing and dry textile fabric, comprising the following steps:

[0096] (1) The aldehyde and ketone resin, epoxy resin, and nano-titanium dioxide of the above-mentioned parts by weight are in a molten state, and the adhesive, softening agent, and surfactant of the above-mentioned parts by weight are added, and the water of 2-10 parts by weight is added to continue Heat and stir for 10-30min, then cool down to 80-85°C, add the collagen fibers and bamboo charcoal fibers in the above parts by weight, mix and stir evenly, and then dry to shape;

[0097] (2) the above-mentioned mixture is made into yarn lines through cleaning, cotton opening, drawing, roving, and spun yarn;

[0098] (3) Knitting or weaving the above-mentioned yarns, and then desizing, washing, drying, and then setting the shape to obtain the fabric.

Embodiment 1

[0103] Embodiment 1 provides a kind of moisture-absorbing and dry textile fabric, which comprises at least the following components in parts by weight: 30 parts of aldehyde and ketone resins, 10 parts of epoxy resins, 30 parts of collagen fibers, 30 parts of bamboo charcoal fibers, and 5 parts of nano-titanium dioxide. 1 part, 3 parts of binder, 10 parts of softener, 1 part of surfactant;

[0104] The aldehyde and ketone resin is the aldehyde and ketone resin of A81;

[0105] The epoxy resin is two ((3,4-epoxycyclohexyl) methyl) adipate;

[0106] The diameter of the collagen fibers is 5-50 μm;

[0107] The diameter of the bamboo charcoal fiber is 0.6 μm-1 μm;

[0108] The nano titanium dioxide is VK-T25F;

[0109] The adhesive is PVA 217;

[0110] The softening agent is aminopropyl-terminated polydimethylsiloxane;

[0111] The surfactant is sorbitan tristearate.

[0112] A method for preparing a moisture-absorbing and dry textile fabric, comprising the steps of:

[0113...

Embodiment 2

[0117] Embodiment 2 provides a kind of moisture-absorbing and dry textile fabric, which comprises at least the following components in parts by weight: 50 parts of aldehyde and ketone resins, 15 parts of epoxy resins, 60 parts of collagen fibers, 50 parts of bamboo charcoal fibers, and 10 parts of nano-titanium dioxide. 8 parts, 8 parts of binder, 20 parts of softening agent, 3 parts of surfactant;

[0118] The aldehyde and ketone resin is the aldehyde and ketone resin of A81;

[0119] The epoxy resin is two ((3,4-epoxycyclohexyl) methyl) adipate;

[0120] The diameter of the collagen fibers is 5-50 μm;

[0121] The diameter of the bamboo charcoal fiber is 0.6 μm-1 μm;

[0122] The nano titanium dioxide is VK-T25F;

[0123] The adhesive is PVA 217;

[0124] The softening agent is aminopropyl-terminated polydimethylsiloxane;

[0125] The surfactant is sorbitan tristearate.

[0126] A preparation method of a moisture-absorbing and dry textile fabric is the same as in Examp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com