A film condensation method for gas dehumidification

A gas and wet gas technology, applied in the field of separation, can solve the problems of reduced heat recovery rate and water vapor recovery efficiency, and achieve the effects of avoiding reheating, increasing membrane penetration rate, and reducing pipeline corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

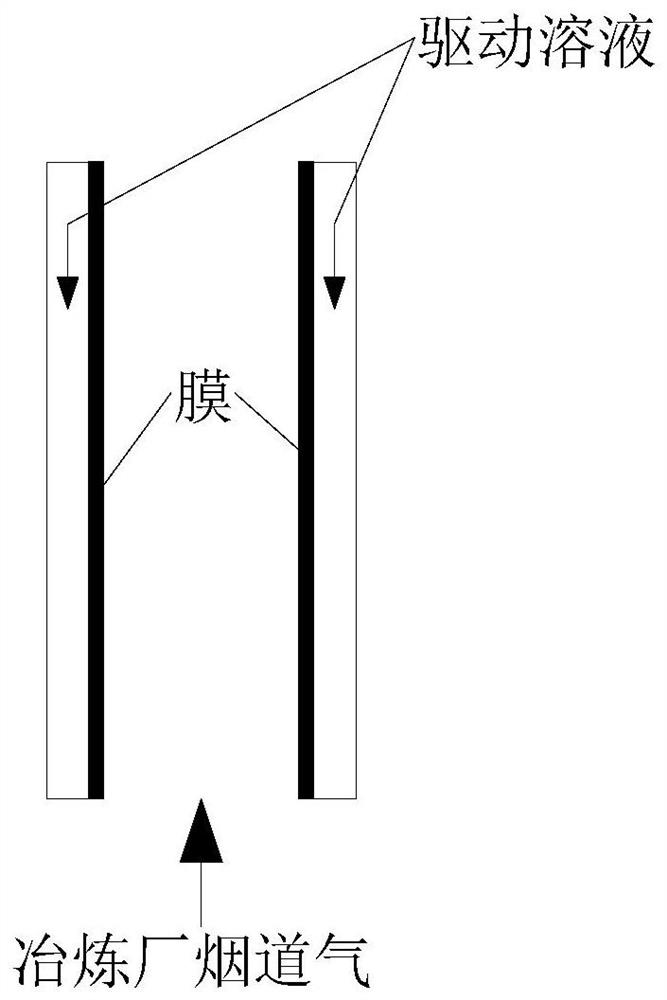

[0041] The present embodiment provides a membrane condensation method for dehumidifying flue gas in a smelter plant. The schematic flowchart of the membrane condensation method is as follows: figure 1 shown, including the following steps:

[0042] (1) The water vapor in the moisture-containing gas with a temperature of 200 °C and a relative humidity of 100% is condensed and transferred through the membrane, and the condensed water is recovered by the driving solution on the liquid side of the membrane; wherein, the moisture-containing gas and the driving solution flow in countercurrent , the flow rate of the membrane surface containing the wet gas is 1m / s, and the flow rate of the driving solution is 3m / s. The driving solution is a NaCl solution with a temperature of 16 ° C and a concentration of 1.5 mol / L; the wet gas is a smelter flue. gas;

[0043] (2) The driving solution after recovering the condensed water is concentrated to a KCl concentration of 1.5 mol / L by means of ...

Embodiment 2

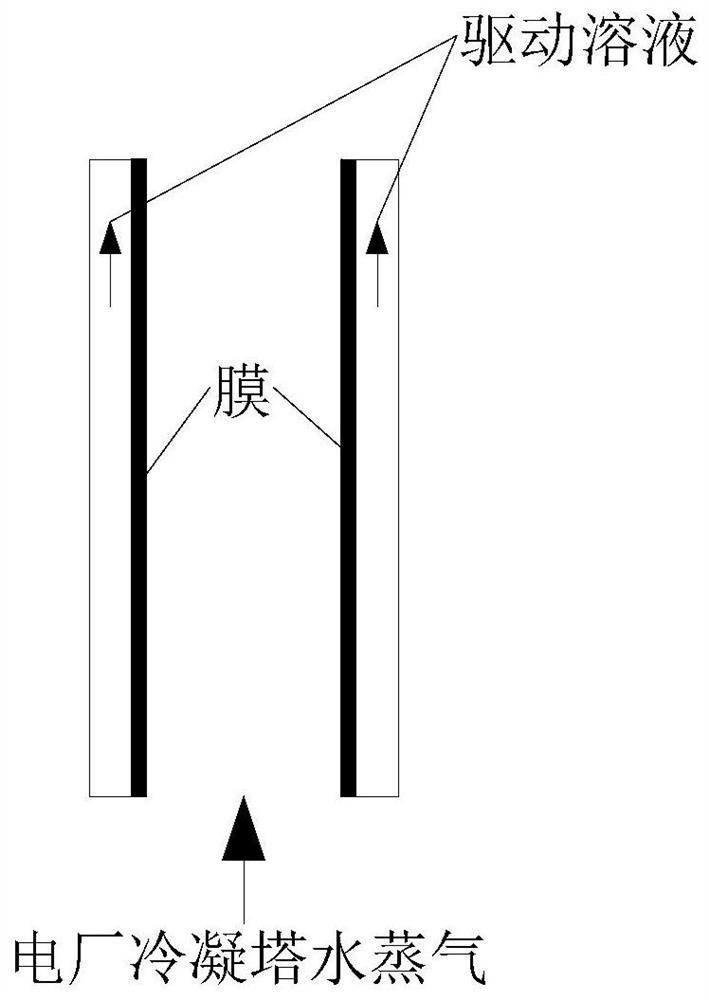

[0045] The present embodiment provides a membrane condensation method for dehumidifying exhaust gas of a coal-fired power plant boiler after desulfurization, and the method includes the following steps:

[0046] (1) The water vapor in the moisture-containing gas with a temperature of 80 °C and a relative humidity of 90% is condensed and transferred through the membrane, and the condensed water is recovered by the driving solution on the liquid side of the membrane; wherein the moisture-containing gas and the driving solution flow countercurrently , the flow rate of the membrane surface of the wet gas is 0.5m / s, the flow rate of the driving solution is 1m / s, and the driving solution is seawater with a temperature of 21 ° C; the wet gas is the desulfurized coal-fired power plant boiler exhaust;

[0047] (2) The driving solution after recovering the condensed water enters the reverse osmosis seawater desalination device to produce pure water, and the recovered water can be used as...

Embodiment 3

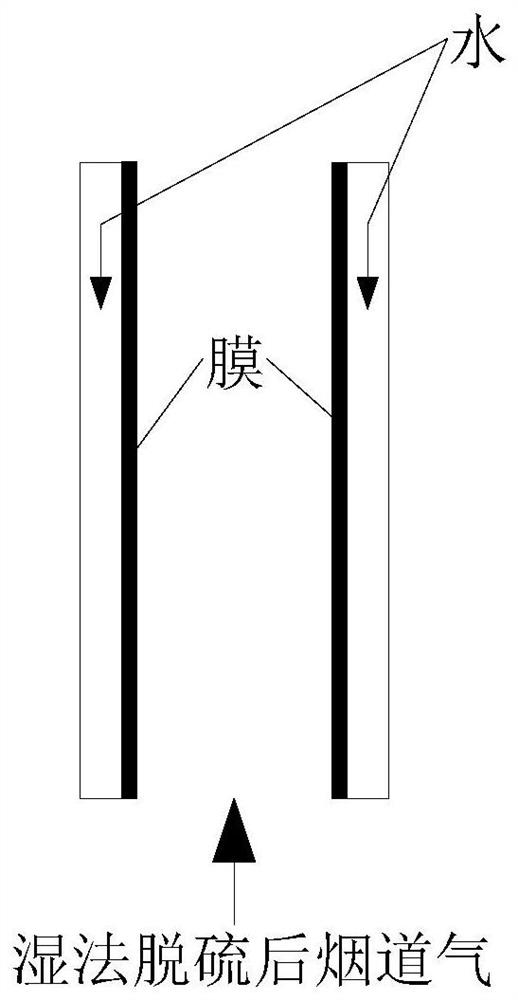

[0049] The present embodiment provides a film condensation method for dehumidifying boiler exhaust gas after reheating, and the method includes the following steps:

[0050] (1) The water vapor in the moisture-containing gas with a temperature of 150 °C and a relative humidity of 60% is condensed and transferred through the membrane, and the condensed water is recovered by the driving solution on the liquid side of the membrane; wherein the moisture-containing gas and the driving solution flow countercurrently , the flow rate of the membrane surface containing the wet gas is 2.5m / s, the flow rate of the driving solution is 5m / s, and the driving solution is seawater desalination reverse osmosis concentrated water with a temperature of 20 ° C; the wet gas is the reheated boiler exhaust gas ;

[0051] (2) The driving solution after recovering the condensed water is used as the reverse osmosis seawater desalination device to produce pure water after the heat is recovered by the he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com