Ultra-clean emission system and method for hazardous waste incineration flue gas

A technology for incinerating flue gas and hazardous waste, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve problems such as excessive acid pollutants, achieve stable emission indicators, improve stability, reduce and remove toxic gases and The effect of impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

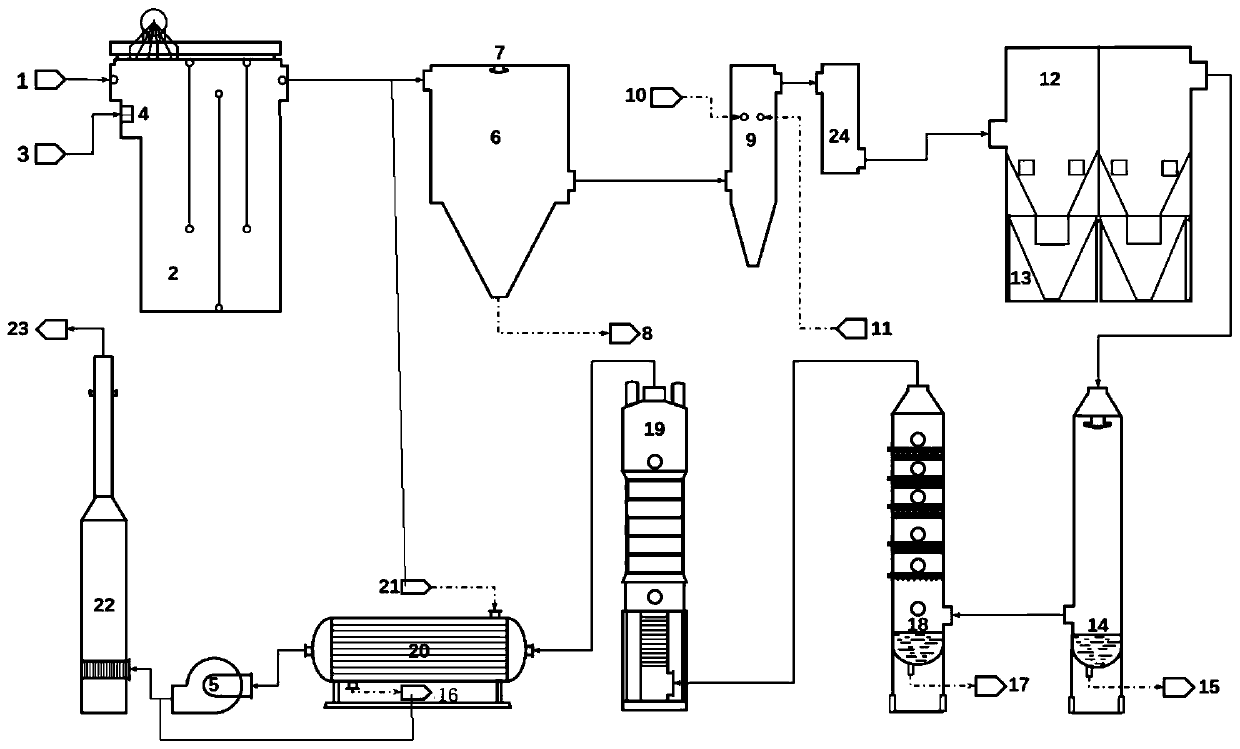

[0032]In order to prolong the service life of each equipment in the process and meet the emission standards of flue gas, it is necessary to control the content of the following elements in the hazardous waste entering the rotary kiln: Clx A reduction reaction occurs with urea, and the removal rate is about 50%.

[0033] After passing through the waste heat boiler, the temperature of the flue gas is reduced to 500-600°C. In order to avoid the synthesis of dioxins during the cooling process, the flue gas enters the quench tower 6 from above through the flue. The quench tower 6 is made of 10mm steel plate + 100mm aluminum silicate fiber felt + 80mm wear-resistant castable, and the top is equipped with a dual-fluid spray system 7, which generates atomized water droplets and rapidly cools the flue gas to below 200°C within 0.8s.

[0034] The cooled flue gas enters the dry deacidification system, and the deacidification tower is made of carbon steel and lined with KPI acid-resistant ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com