A kind of aluminum nitride/nanometer silver solder paste heat conduction material and preparation method thereof

A heat-conducting material and nano-silver technology, applied in welding/cutting media/materials, welding equipment, manufacturing tools, etc., can solve problems such as easy agglomeration, difficult adhesion, gaps in nano-silver solder paste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

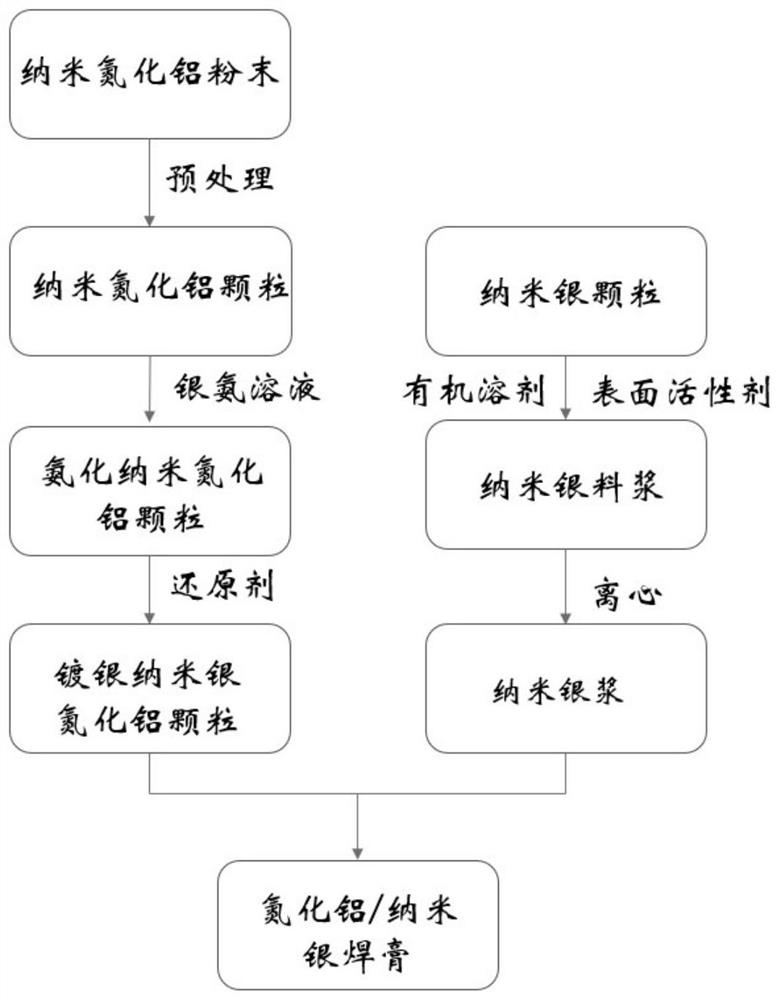

Method used

Image

Examples

Embodiment 1

[0033] (1) Add 0.8g of nano-aluminum nitride particles to 25ml of concentrated sulfuric acid solution, boil at 100°C for 8h, perform coarsening treatment, and then place them in 0.15mol / L SnCl 2 2H 2 The sensitization treatment was carried out in the sensitization solution of O, and finally placed in 0.025mol / LPdCl 2 Activation treatment is carried out in the concentrated hydrochloric acid (38wt%) mixed solution;

[0034] (2) Modifying the nano-aluminum nitride particles, adding 0.4 g of pretreated nano-aluminum nitride particles into 15 ml of pure ammonia solution at room temperature to obtain ammoniated nano-aluminum nitride particles. Then, a 0.1 mol / L silver nitrate aqueous solution was added dropwise to the analytically pure ammonia solution, and 0.15 g of sodium dodecylbenzenesulfonate was added thereto to obtain a mixed silver ammonia solution. Then add the ammoniated nano-aluminum nitride particles into the mixed silver-ammonia solution, perform magnetic stirring in ...

Embodiment 2

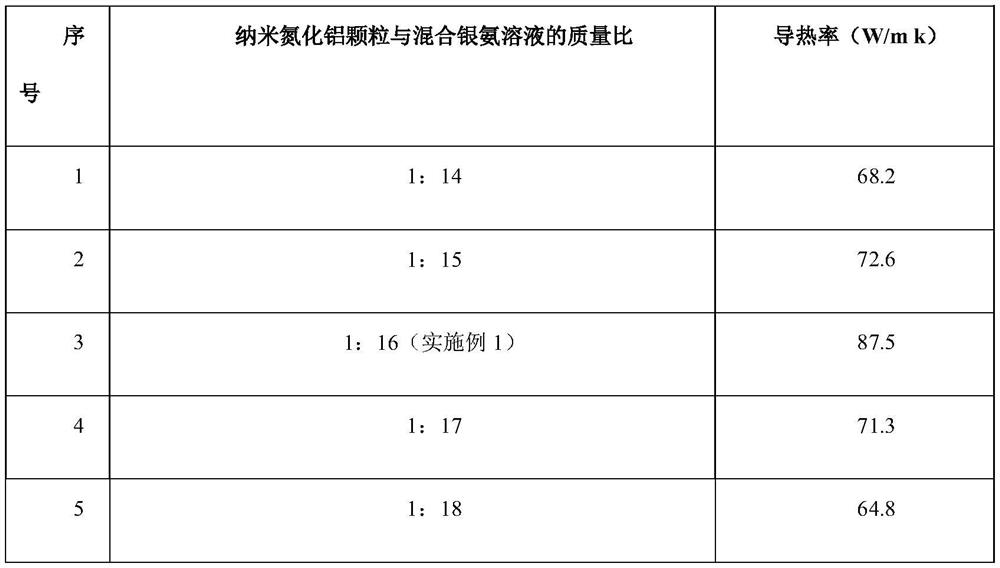

[0039] Other conditions were the same as in Example 1, and the properties of the materials prepared with different mass ratios of nano-aluminum nitride particles and mixed silver-ammonia solutions were tested. The experimental results are shown in Table 1.

[0040] Table 1 The performance of different nano-aluminum nitride particles and mixed silver-ammonia solution mass ratio on the performance of thermal conductive materials

[0041]

[0042] From the above results, it can be seen that the mass ratio of nano-aluminum nitride particles to mixed silver-ammonia solution is preferably 1:16

[0043] (Example 1).

Embodiment 3

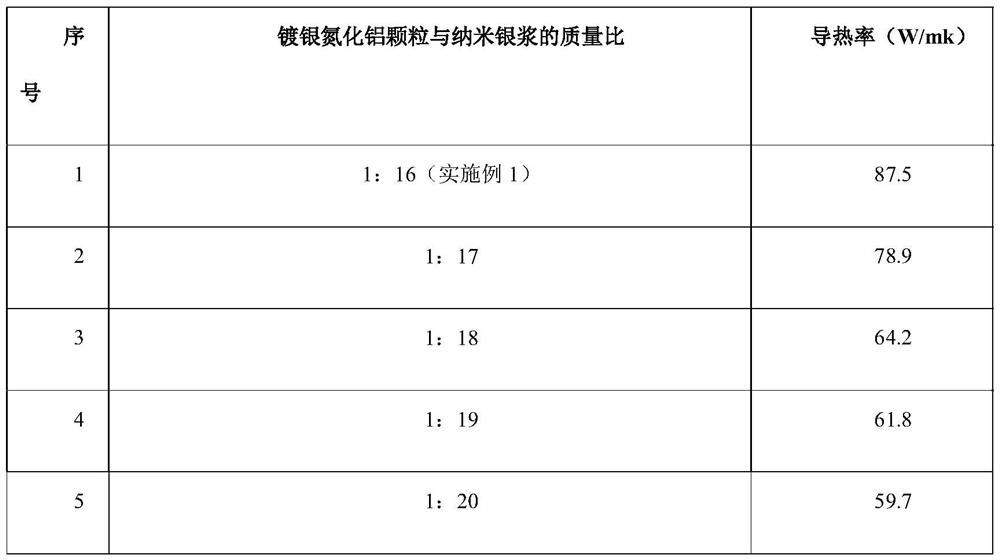

[0045] Other conditions were the same as in Example 1, and the properties of the materials prepared with different mass ratios of silver-plated aluminum nitride particles to nano-silver paste were tested. The experimental results are shown in Table 2.

[0046] Table 2 The performance of different silver-plated aluminum nitride particles and nano-silver paste on the performance of thermal conductivity materials

[0047]

[0048] It can be seen from the above results that the mass ratio of silver-plated aluminum nitride particles to nano-silver paste is preferably 1:16 (Example 1).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com