Device and method for preparing embedded laminated structure

A technology of laminated structure and preparation device, applied in coating devices, manufacturing auxiliary devices, processing and manufacturing, etc., can solve the problems of upper and lower structure asymmetry, low structure and shape accuracy, low efficiency, etc., to avoid upper and lower asymmetry, The effect of improving efficiency and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

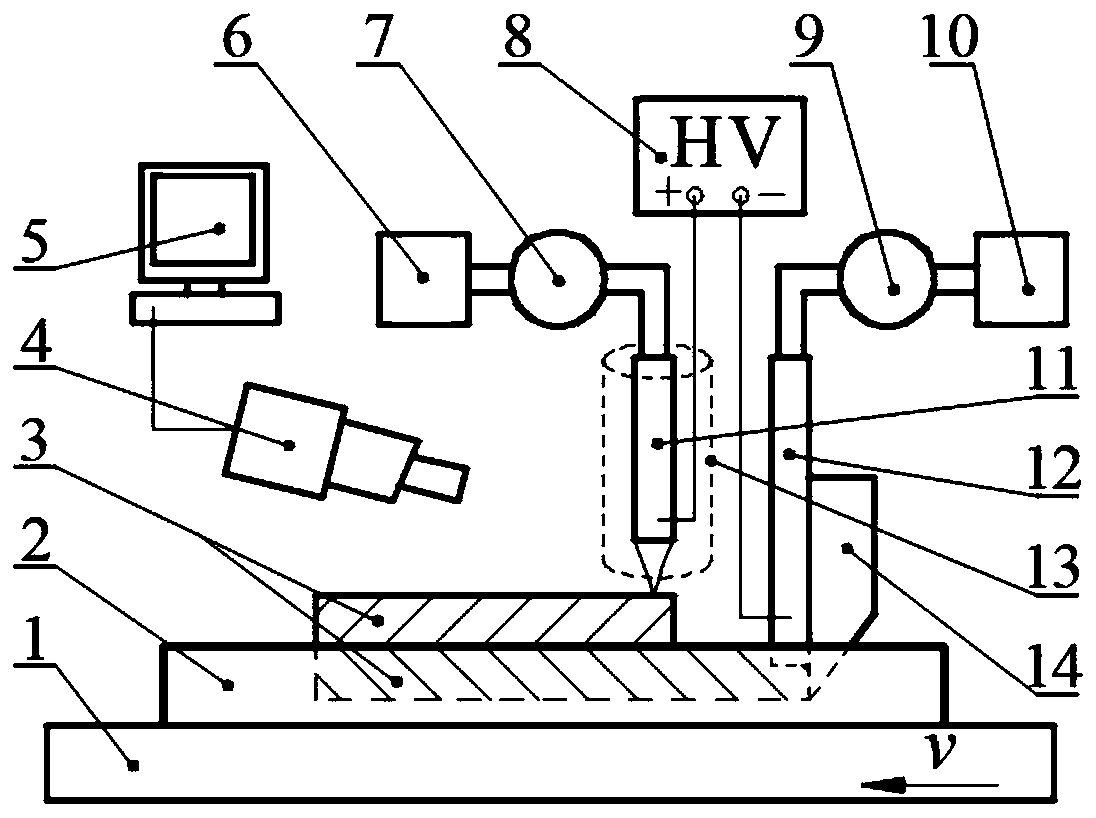

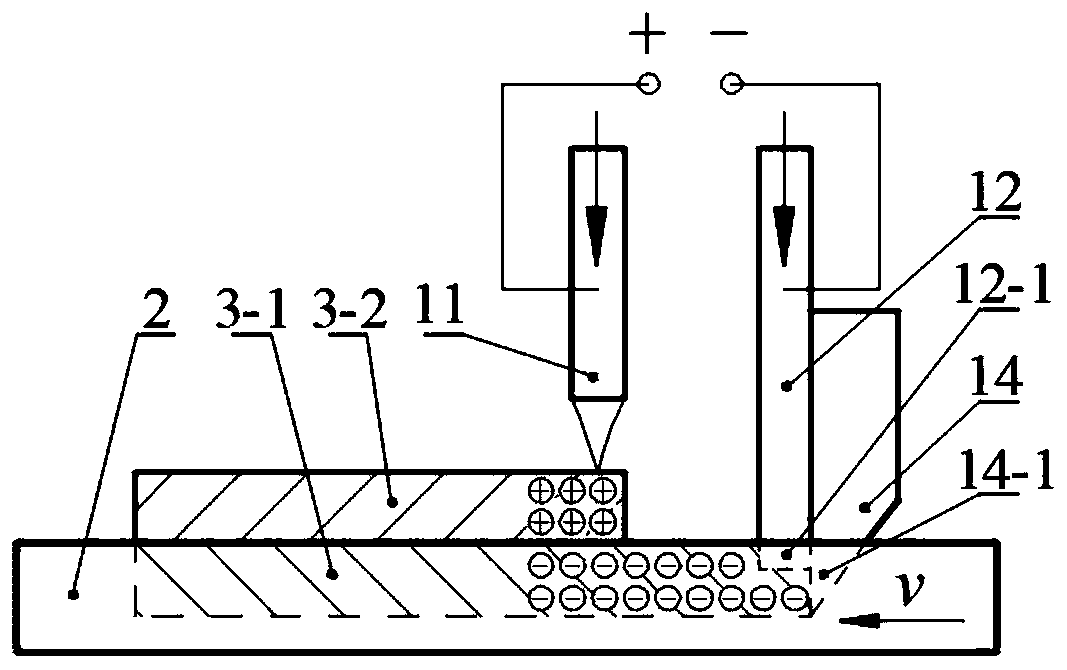

[0046] Embodiment 1: a kind of embedded laminated structure preparation device, specifically as follows:

[0047] The upper nozzle 11 and the lower nozzle 12 are vertically arranged in parallel, both are made of conductive materials, and the inner diameter ranges from 50 μm to 1500 μm. The lower nozzle 12 is lower than the upper nozzle 1110 μm to 3000 μm. In this embodiment, a dispensing flat needle is used as the upper nozzle 11 , the lower shower head 12.

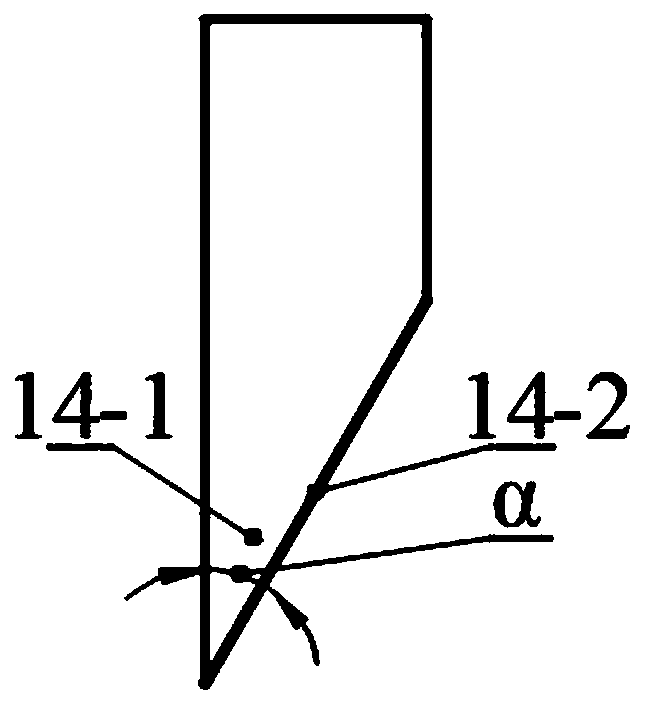

[0048]The single-edged blade 14 is arranged on the side of the lower nozzle 12 , and the blade tip 14 - 1 is located 10 μm to 3000 μm below the lower nozzle 12 . The length range of blade 14-2 is 2mm~50mm, and the value range of blade included angle α is 10°~60°. The alpha value is 30°.

[0049] An upper liquid storage tank 6 and an upper layer solution pump 7 are provided. The upper liquid storage tank 6, the upper layer solution pump 7 and the upper layer nozzle 11 are connected to each other. The upper layer liquid s...

Embodiment 2

[0060] Embodiment 2: A method for preparing an embedded laminated structure, using the device for preparing an embedded laminated structure provided in the above embodiment.

[0061] In this embodiment, the substrate 2 is PDMS, the upper layer solution is a PEO solution (12% concentration, the solute is PEO, the solvent is alcohol and distilled water, and the volume ratio is 1:1), the inner diameter of the upper nozzle 11 is 210 μm, and the lower layer solution is a PVDF solution (Concentration is 15%, solute is PVDF, solvent is acetone and DMF mixed solvent, volume ratio is 1:1), the inner diameter of the lower nozzle 12 is 260 μm, the lower nozzle 12 is located 50 μm below the upper nozzle 11, and the knife tip 14-1 is located in the lower nozzle 20 μm below 12. The positive pole of the high voltage power supply 8 is electrically connected to the upper nozzle 11 , and the negative pole of the high voltage power supply 8 is electrically connected to the lower nozzle 12 .

[...

Embodiment 3

[0070] Embodiment 3: A method for preparing an embedded laminated structure, using the device for preparing an embedded laminated structure provided in the above embodiment.

[0071] In this embodiment, the substrate 2 is PDMS, the upper layer solution is a PEO solution (15% concentration, the solute is PEO, the solvent is alcohol and distilled water, and the volume ratio is 1:1), the inner diameter of the upper nozzle 11 is 320 μm, and the lower layer solution is a graphite solution (the concentration is 13%, the solute is 99.5% high-purity flake graphite, the solvent is polyethylene oxide (PEO) and N-methylpyrrolidone (NMP), and the volume ratio is 1:1), the inner diameter of the lower nozzle 12 is 260 μm, and the lower nozzle 12 It is located 50 μm below the upper nozzle 11 , and the knife tip 14 - 1 is located 20 μm below the lower nozzle 12 . The positive pole of the high voltage power supply 8 is electrically connected to the upper nozzle 11 , and the negative pole of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com