Method for preparing high-quality large-size graphene on large scale

A large-scale preparation and graphene technology, applied in graphene, chemical instruments and methods, nano-carbon, etc., can solve the problems of low production efficiency and long ball milling time, and achieve the goal of improving production efficiency, short ball milling time, and avoiding impurities Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

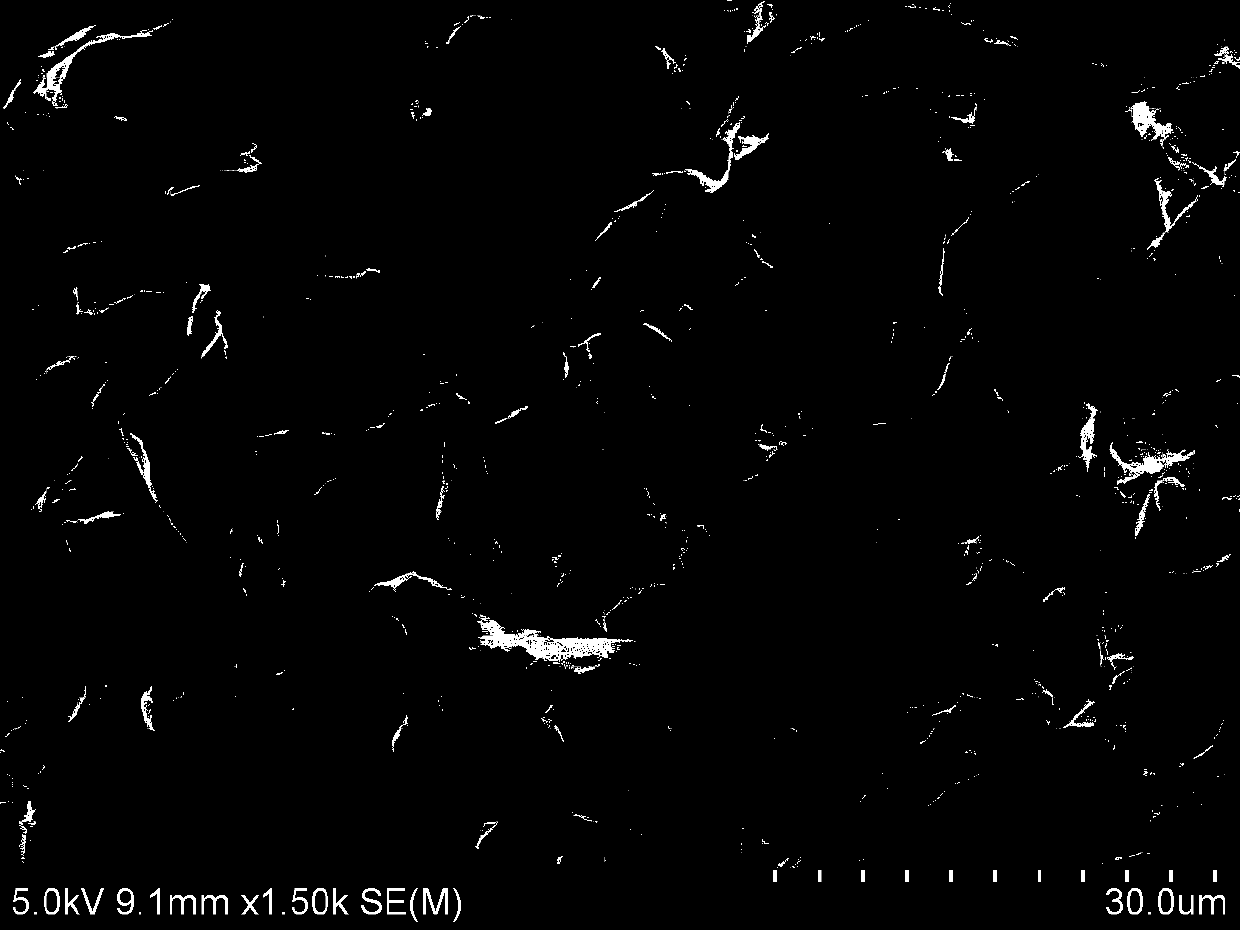

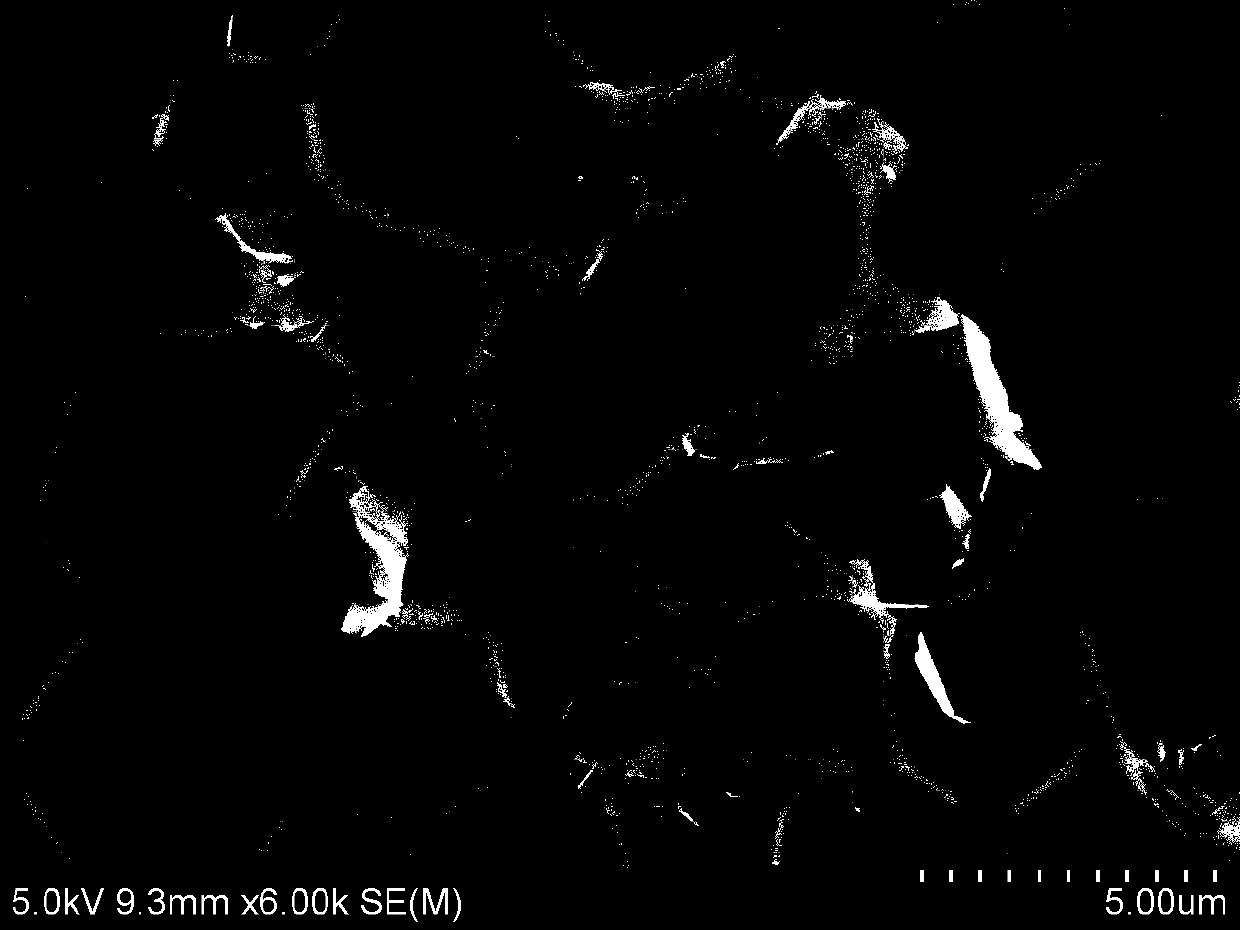

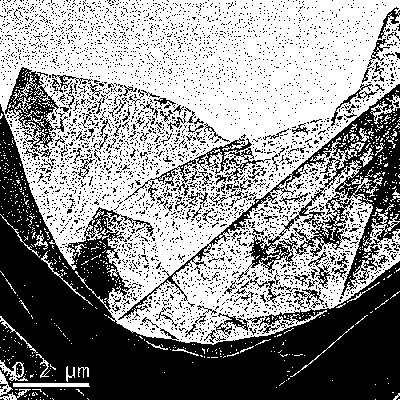

[0039] Take by weighing 1g 80 mesh original graphite powder and put it into the ball mill jar of planetary ball mill, and add an appropriate amount of mass fraction therein to be 10% perchloric acid solution, the addition is to reach two-thirds of the ball mill jar as the criterion, and then add Fill the ball mill jar with argon and seal it, put it into a planetary ball mill and react for 1 hour with 200 rpm ball mill, filter and collect the perchloric acid solution with a mass fraction of 10% for reuse, and grind the graphite powder after ball milling at 80 After fully drying in a blast drying oven at ℃, take 2 ml of perchloric acid solution with a mass fraction of 72% and mix it evenly in a crucible, then place the crucible in a tube furnace and heat it to 170 °C under an argon protective atmosphere Insulate for 1h, after the tube furnace cools down, ultrasonically disperse the obtained graphene aggregates in absolute ethanol with a purity of 99%, and finally dry in air to ob...

Embodiment 2

[0041]Take by weighing 1g 32 order original graphite powders and put into the ball mill jar of planetary ball mill, and add the perchloric acid solution that an amount of mass fraction is 10% wherein, the addition is to reach two-thirds place of ball mill jar as the criterion, then Fill the ball mill jar with argon and seal it, put it into a planetary ball mill and react for 2 hours at 100 rpm, filter and collect the perchloric acid solution with a mass fraction of 10% for reuse, and grind the graphite powder at 80 After fully drying in a blast drying oven at ℃, take 2 ml of perchloric acid solution with a mass fraction of 72% and mix it evenly in a crucible, then place the crucible in a tube furnace and heat it to 200 °C under an argon protective atmosphere Keep warm for 1h, after the tube furnace cools down, ultrasonically disperse the obtained graphene aggregates in absolute ethanol with a purity of 99%, and finally dry in air to obtain a size of 160 μm 2 , with a conductiv...

Embodiment 3

[0043] Take by weighing 0.05g 500 mesh original graphite powder and put it into the ball milling jar of planetary ball mill, and add an appropriate amount of mass fraction therein to be 10% perchloric acid solution, the addition is to reach two-thirds of the ball milling jar as the criterion, then Fill the ball mill jar with argon and seal it, put it into a planetary ball mill and react for 0.5h with 500 rpm ball mill, filter and collect the perchloric acid solution with a mass fraction of 10% for reuse, and put the ball milled graphite powder in After being fully dried in a blast drying oven at 80°C, measure 1 ml of perchloric acid solution with a mass fraction of 72% and mix it evenly in a crucible, then place the crucible in a tube furnace and heat it to 180 °C under an argon protective atmosphere. ℃ for 0.5h, after the tube furnace is cooled, the obtained graphene aggregates are ultrasonically dispersed in absolute ethanol with a purity of 99%, and finally dried in the air ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com