A kind of production method of phloroglucinol

A technology of phloroglucinol and its production method, applied in the field of bioengineering, can solve the problems of expensive raw materials of phloroglucinol, complex separation and purification process, environmental pollution of by-products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

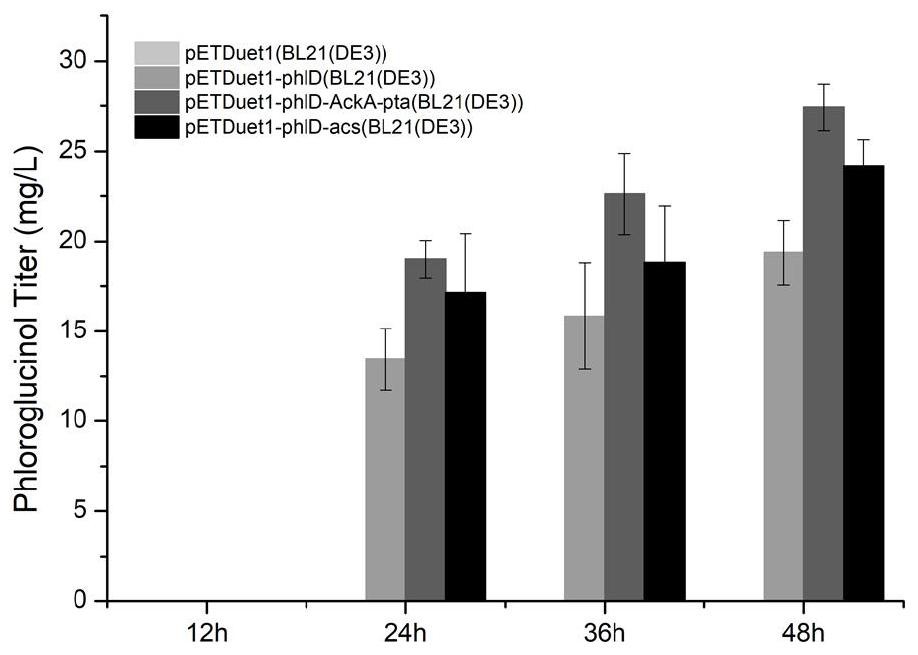

[0021] Embodiment 1, the determination of acetic acid production phloroglucinol approach:

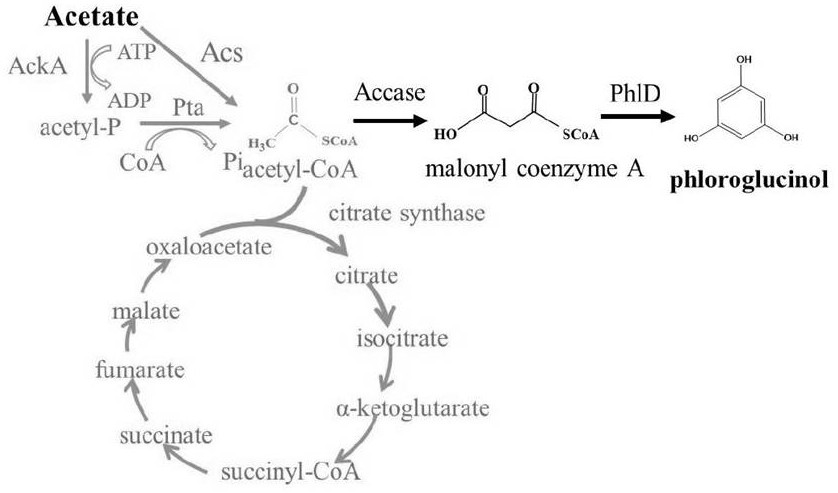

[0022] Acetate can be catalyzed by acetyl-CoA synthase (Acs or AckA and Pta) to generate malonyl-CoA, and malonyl-CoA can be catalyzed by phloroglucinol synthase (PhlD) to generate phloroglucinol. The target genes PhlD, Acs, AckA and Pta were synthesized according to the gene synthesis method. The synthetic gene fragment PhlD was connected with the backbone PETDuet-1 to construct the plasmid pET-phlD. The fragments Acs, AckA and Pta were ligated with the backbone pET-phlD by Gibson's method to construct plasmids pET-phlD-acs and pET-phlD-ackA-pta. The plasmids pETDuet-1, pET-phlD, pET-phlD-acs and pET-phlD-ackA-pta were transformed into Escherichia coli BL21(DE3) respectively to obtain strains BL21(DE3)(pETDuet-1), BL21(DE3) (pET-phlD), BL21(DE3)(pET-phlD-acs) and BL21(DE3)(pET-phlD-ackA-pta). After a single colony grows, it is inoculated into LB liquid medium, cultured at 37°C for 8...

Embodiment 2

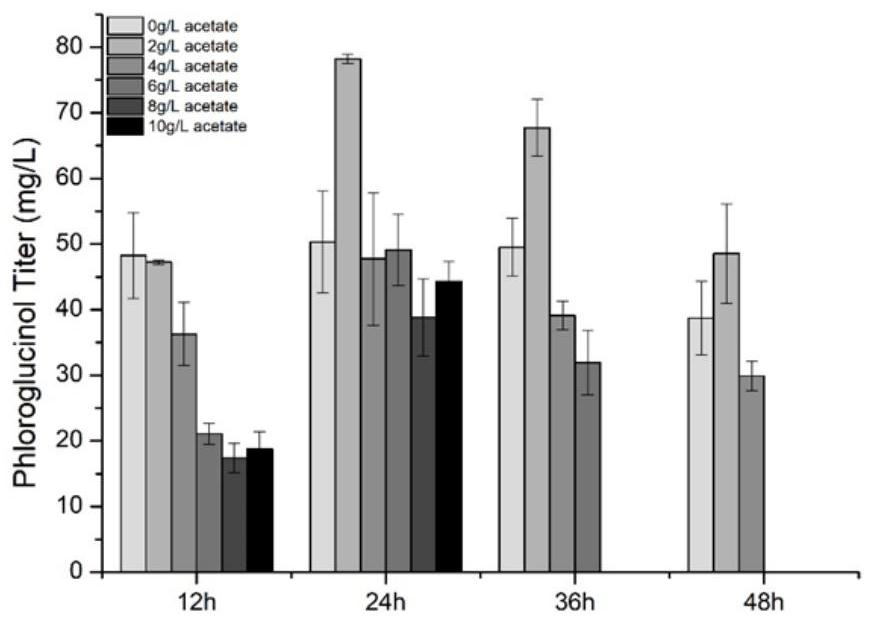

[0026] Embodiment 2, optimization M9 fermentation medium condition

[0027] The plasmid pET-phlD-ackA-pta was transferred into Escherichia coli BL21 (DE3), inoculated in 5mL liquid LB medium after growing a single colony, and transferred to cells containing different concentrations of acetic acid (0g) with 1% inoculum after overnight culture. / L, 2g / L, 4g / L, 6g / L, 8g / L, 10g / L) M9 fermentation medium, cultured in shake flasks. Take the fermented liquid every 12 hours and check the output. Fermentation results such as image 3 shown. It can be seen from the figure that the yield of fermentation in the medium containing 2g / L acetic acid was the highest at 24h, which was 78.21mg / L. Therefore, 2g / L acetic acid is the optimum concentration for phloroglucinol production. On this basis, the optimized 2g / L acetic acid concentration was used to optimize the concentration of yeast extract in M9 medium. Escherichia coli BL21 (DE3) (pET-phlD-ackA-pta) was used as the target strain, an...

Embodiment 3

[0030] Embodiment 3, utilize CRISPRi to improve phloroglucinol output

[0031]Verify the blocking effect of dCas9. The target fragments egfp and egfp-sgRNA were obtained by PCR, and the target fragments were connected to the backbone pZE and pCS-dCas9 respectively by Gibson's method to construct plasmids pZE-pferB-egfp and pCS-dCas9-egfp-sgRNA. After the construction, the two plasmids were co-transformed into Escherichia coli BL21(DE3), and after a single colony grew, they were inserted into 5 mL LB liquid medium for overnight culture. Then transfer the seed solution to a new 5mL liquid LB medium with a 1% inoculum amount, add IPTG with a final concentration of 1mM and corresponding antibiotics and culture it on a shaker at 37°C, and detect the fluorescence and OD after 4 hours 600 Value, after this; = check once every two hours. The result is as Figure 5 As shown, after culturing for 4 hours, the fluorescence intensity / OD of the control group BL21(DE3)(pCS-dCas9+PferB-egf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com