Method for preparing test sample using FIB and test sample

A technology for testing samples and samples, which is applied in the field of preparing test samples by FIB, can solve the problems that it is difficult to obtain EBSD test samples that meet the requirements, affect the crystal plane Bragg diffraction Kikuchi pattern, and affect the accuracy of test results, etc., and achieve the reduction of deformation tendency , avoid deformation, reduce the effect of adjustment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The method for preparing a test sample by using FIB provided by the present invention and the specific implementation of the test sample will be described in detail below in conjunction with the accompanying drawings.

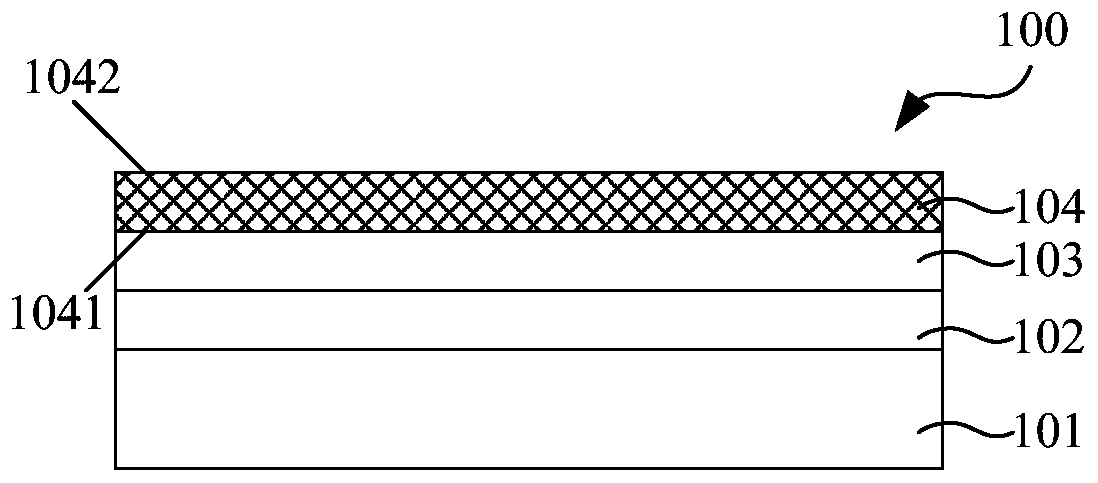

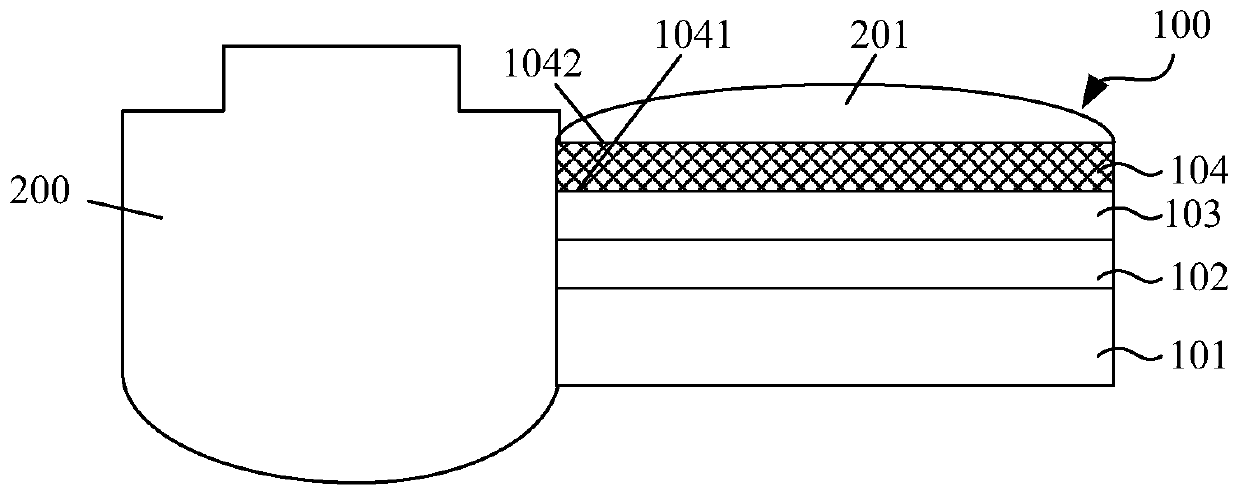

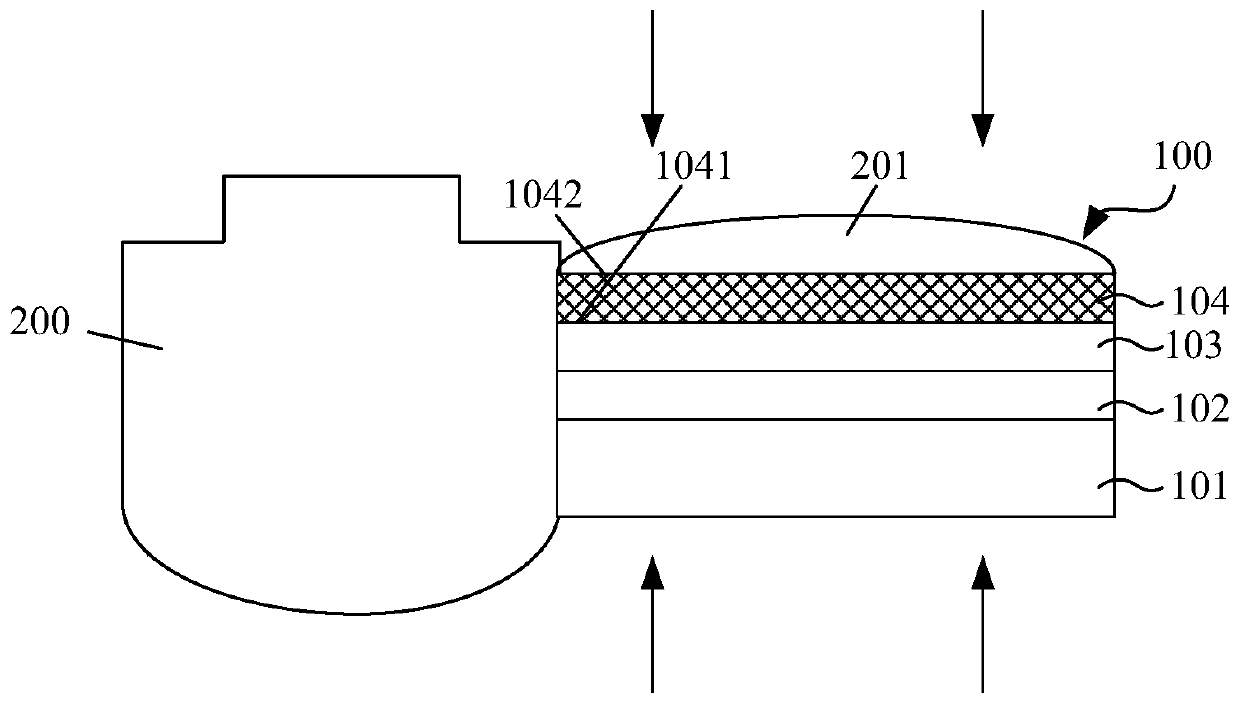

[0025] Please refer to figure 1 , providing a pretreated sample 100 having a target layer 104 having opposing first surfaces 1041 and second surfaces 1042 .

[0026] In this specific embodiment, the pretreatment sample is a pretreatment sample taken from the unstructured wafer (Blanket Wafer) used for adjusting the process adjustment of 3D NAND products by focusing ion beam (FIB).

[0027] The pretreated sample 100 includes: a single crystal silicon layer 101 , a silicon oxide layer 102 , a Ta layer and a target layer 104 , and the target layer 104 is a copper seed layer. In this specific embodiment, the copper seed layer is used as the target layer 104, and the target layer 104 is thinned to a target thickness as a sample for T-EBSD testing. In this ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com