MTO reaction kinetic model, MTO reaction regeneration integrated model and application thereof

A technology of reaction kinetics and reaction regeneration, applied in the chemical industry, can solve the problems of no further verification of model practicability, calculation prediction error, poor data correlation, etc., and achieve the effect of practicability and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

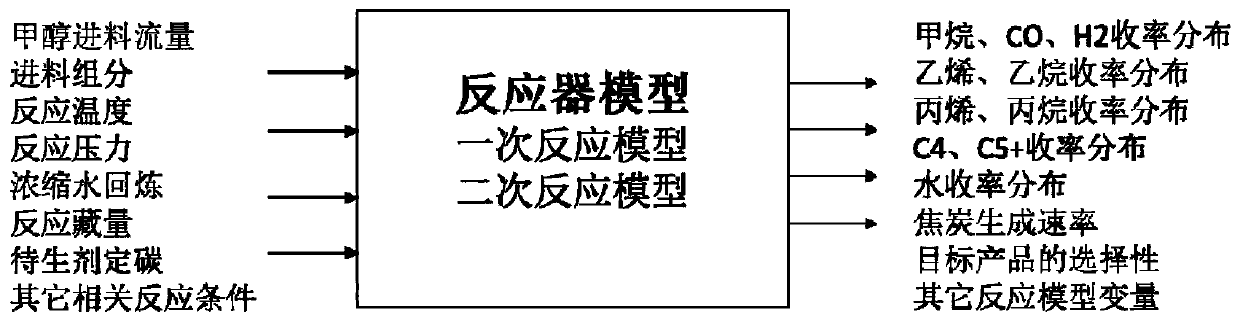

[0122] As a specific embodiment of the present invention, Lumped Model of MTO Reaction Kinetics The build methods include:

[0123] Divide the reaction system into the following lumped components:

[0124] Lumped P1-Methanol; Lumped P2-Methane (C1); Lumped P3-Ethane (C2); Lumped P4-Ethylene (C2=); Lumped P5-Propane (C3); Lumped P6-Propane ( C3=); lumped P7-carbon 4 (C4); lumped P8-carbon 5 and above (C5+); lumped P9-hydrogen; lumped P10-carbon monoxide; lumped P11-carbon dioxide; lumped P12-coke.

[0125] Among them, the main reaction products of the MTO reaction are two lumped components of ethylene and propylene, and other lumped components are by-products.

[0126] According to the reaction mechanism between the above-mentioned lumped components, the reaction paths (including primary and secondary reactions) between the above-mentioned lumped components were determined to construct the reaction network, and the reaction kinetic equation was determined.

[0127] In this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com