Porous silicon/carbon shell composite material and preparation method and application thereof

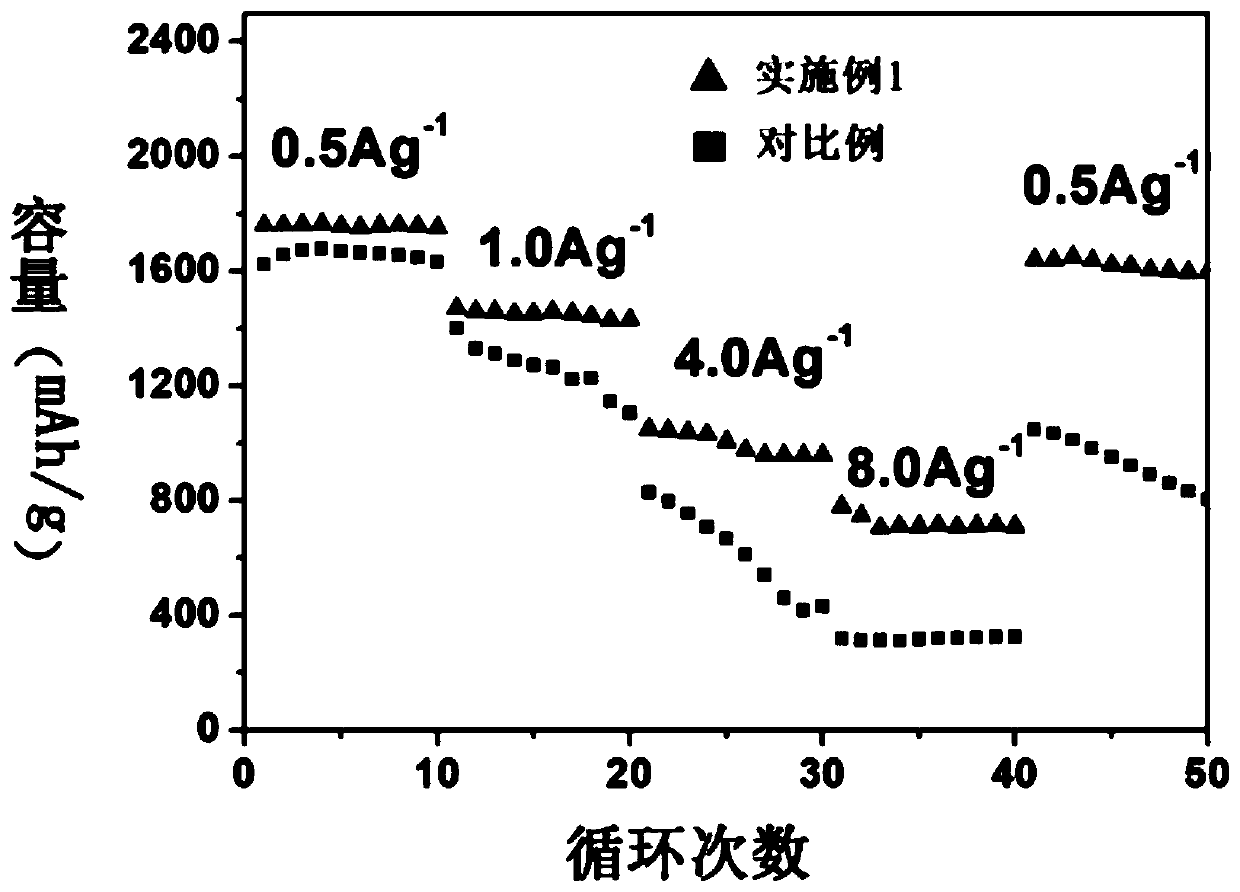

A composite material, porous silicon technology, applied in the direction of active material electrodes, structural parts, electrical components, etc., can solve problems such as few electron and lithium ion transport sites, poor rate performance, and inability to achieve rapid charge transport.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] 1) Dissolve 1g of phenolic resin (Aladdin) in 100mL of toluene, and then disperse magnesium silicide powder in the solution. The mass ratio of magnesium silicide and phenolic resin is 10:1. After stirring evenly, the toluene was completely evaporated to dryness at 120° C. to obtain a mixture of magnesium silicide / phenolic resin.

[0050] 2) The mixture obtained in step 1) was heat-treated under a nitrogen atmosphere at a temperature of 700° C. for 10 h.

[0051] 3) The product obtained in step 2) is subjected to pickling treatment. Pickling is carried out with excess dilute hydrochloric acid. The concentration of dilute hydrochloric acid is 1mol / L. After cleaning, it is washed 5 times with deionized water, and then dried to form a composite material of porous silicon / carbon shell.

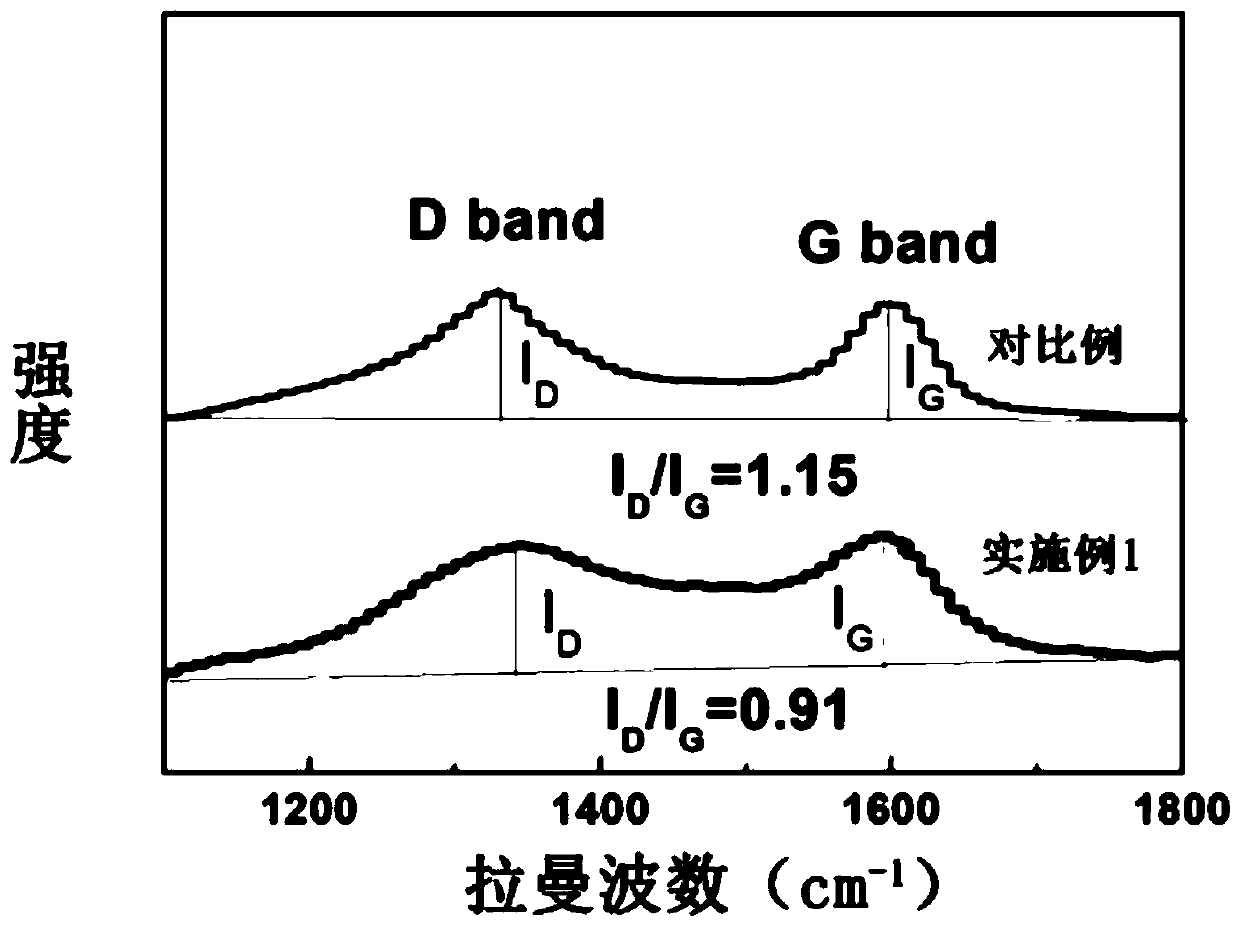

[0052] After testing, the particle size of the porous silicon / carbon shell composite material prepared in this embodiment is 1-5 μm, the thickness of the carbon layer is about 12-15 nm, and...

Embodiment 2

[0056] The same raw materials and preparation process as in Example 1 were used, the only difference being that the mass ratio of magnesium silicide to phenolic resin was 5:1.

[0057] Through Raman test, the porous silicon / carbon shell composite material prepared in this embodiment, the ratio I of amorphous carbon peak and graphitized carbon peak D / I G is 0.99.

Embodiment 3

[0059] The same raw materials and preparation process as in Example 1 were used, the only difference being that the mass ratio of magnesium silicide to phenolic resin was 1:1.

[0060] Through Raman test, the porous silicon / carbon shell composite material prepared in this embodiment, the ratio I of amorphous carbon peak and graphitized carbon peak D / I G is 1.06.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com