Flue gas white removal system and method based on partial organic Rankine cycle

A technology of Rankine cycle and flue gas, applied in separation methods, chemical instruments and methods, solid separation, etc., can solve the problems of low flue gas lift height, low wet flue gas temperature, incomplete whitening, etc., and achieve energy saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

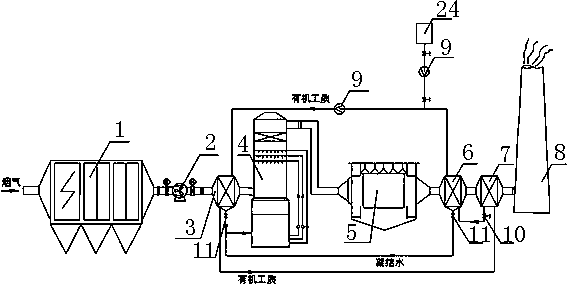

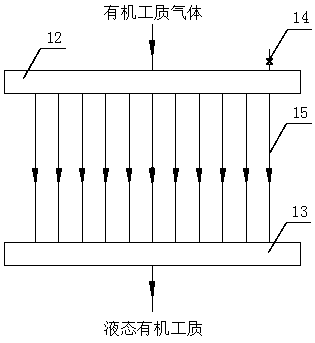

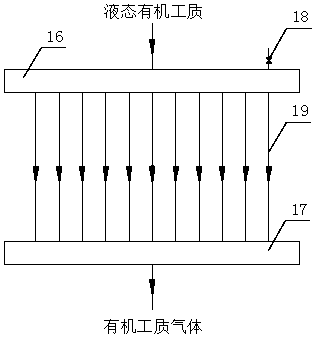

[0052] like Figure 1 to Figure 4 As shown, a flue gas dewhitening system based on partial organic Rankine cycle, including electric bag filter 1, induced draft fan 2, waste heat recovery stage 3 of flue gas multi-stage deep cooling system, desulfurization tower 4, wet electrostatic precipitator 5 , Flue gas multi-stage deep cooling system dehumidification stage 6 and flue gas heating system 7. The type of flue gas may be flue gas discharged from coal-fired boilers.

[0053] The inlet of the induced draft fan 2 is connected to the outlet of the electric bag filter 1 through the flue, which is used to overcome the system resistance of the flue gas flow. The outlet of the desulfurization tower 4 is connected to the outlet of the waste heat recovery stage 3 of the flue gas multi-stage deep cooling sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com