Flue gas desulfurization method using secondary zinc oxide soot as desulfurizing agent

A technology of secondary zinc oxide and desulfurizer, applied in chemical instruments and methods, separation methods, zinc sulfate, etc., can solve the problems of lengthy process, high grade and impurity requirements of secondary zinc oxide, and reduce equipment blockage and scaling, economical Significant environmental protection benefits, significant technological advancement and promotional effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

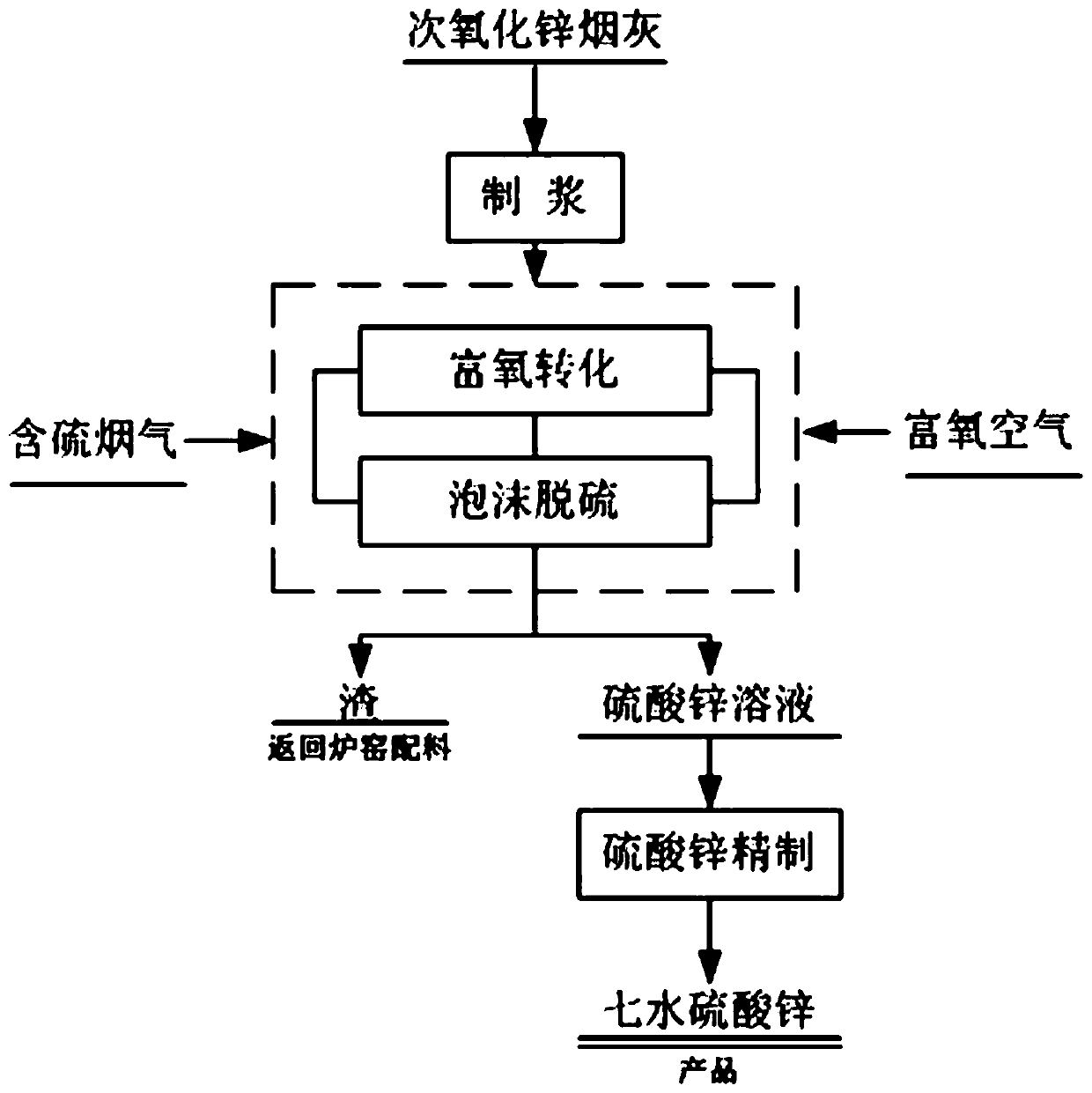

Image

Examples

Embodiment 1

[0034] Using the hazardous waste treatment metallurgical furnace flue gas desulfurization of an environmental protection enterprise, the flue gas volume to be treated is 60000m 3 / h, flue gas SO 2 Concentration 3500mg / m 3 , The secondary zinc oxide soot composition used is: zinc 26.8%, tin 2.56%, lead 0.74%, copper 1.25%, nickel 0.98%.

[0035] The above-mentioned secondary zinc oxide soot is carried out according to the following process steps:

[0036] 1. Pulping, mixing sub-zinc oxide soot with clean water or subsequent process return liquid to make slurry, controlling the liquid-solid ratio to 6:1, stirring at room temperature for 30 minutes, and sending the overflowed slurry to the oxygen-enriched conversion-foam desulfurization process;

[0037] 2. Oxygen-enriched conversion-foam desulfurization, mix the overflow slurry in the previous stage of the process with 1% foaming agent in the transfer tank, and after stirring, inject it into the liquid storage pool at the bott...

Embodiment 2

[0040] Using the hazardous waste treatment metallurgical furnace flue gas desulfurization of an environmental protection enterprise, the flue gas volume to be treated is 60000m 3 / h, flue gas SO 2 Concentration 3500mg / m 3 , The subzinc oxide soot composition used is: zinc 61.36%, tin 0.09%, lead 2.74%, copper 0.25%, nickel 0.08%.

[0041] The above-mentioned secondary zinc oxide soot is carried out according to the following process steps:

[0042] 1. Pulping, mixing secondary zinc oxide soot with clean water or subsequent process return liquid to make slurry, controlling the liquid-solid ratio to 10:1, stirring at room temperature for 30 minutes, and sending the overflowed slurry to the oxygen-enriched conversion-foam desulfurization process;

[0043] 2. Oxygen-enriched conversion-foam desulfurization, mix the overflow slurry in the previous stage of the process with 3% foaming agent in the transfer tank, and after stirring, inject it into the liquid storage pool at the bot...

Embodiment 3

[0046] Using the hazardous waste treatment metallurgical furnace flue gas desulfurization of an environmental protection enterprise, the flue gas volume to be treated is 60000m 3 / h, flue gas SO 2 Concentration 3500mg / m 3 , The subzinc oxide soot composition used is: zinc 39.12%, tin 0.08%, lead 5.04%, copper 3.25%, nickel 1.28%.

[0047] The above-mentioned secondary zinc oxide soot is carried out according to the following process steps:

[0048] 1. Pulping, mixing sub-zinc oxide soot with clean water or subsequent process return liquid to make slurry, controlling the liquid-solid ratio to 8:1, stirring at room temperature for 30 minutes, and sending the slurry to the oxygen-enriched conversion-foam desulfurization process after overflow;

[0049] 2. Oxygen-enriched conversion-foam desulfurization, mix the overflow slurry in the previous stage of the process with 3% foaming agent in the transfer tank, and after stirring, inject it into the liquid storage pool at the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com