Method for enriching and recycling niobium, rare earth and titanium from polymetallic ore containing iron, niobium and rare earth

A polymetallic ore and rare earth technology, applied in the field of niobium resource utilization, can solve problems such as low grade, difficulty in high-efficiency enrichment of niobium ore phases, failure to meet high-grade ferroniobium production standards, etc., and achieve strong process operability and economical rationality , The effect of simple process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A method for enriching and recovering niobium, rare earth and titanium from polymetallic ores containing iron, niobium and rare earth, comprising the following steps:

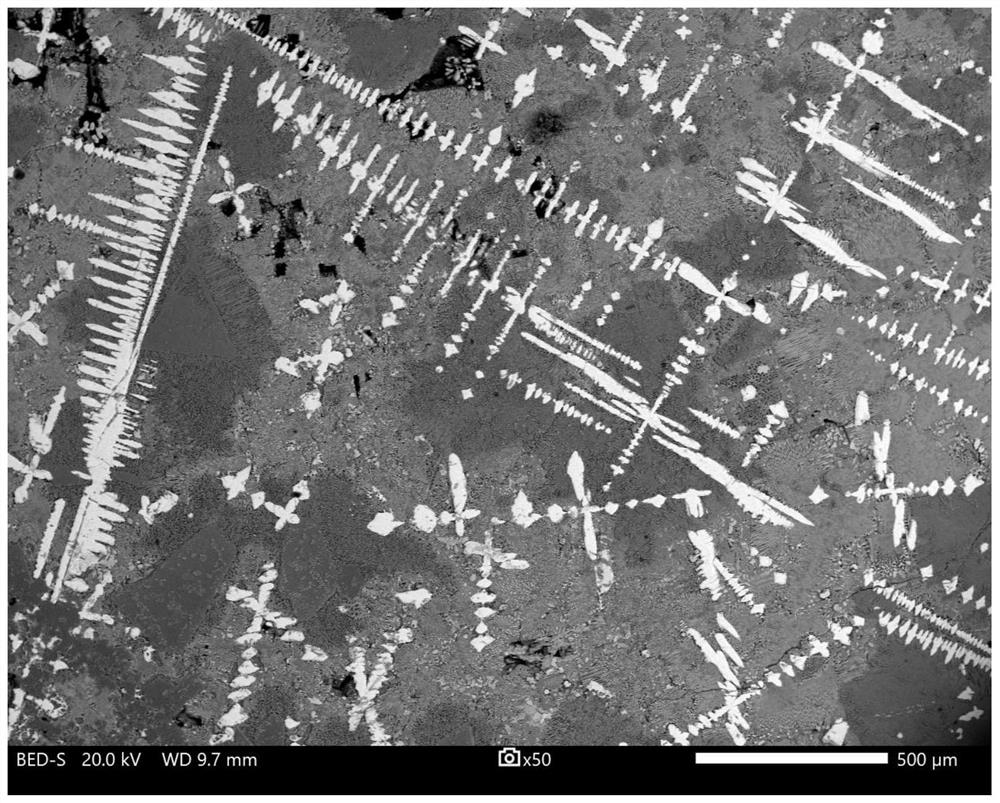

[0041] (1) Complex ore materials containing low-grade niobium / rare earth / titanium (such as low-grade niobium concentrate obtained from primary beneficiation, the Nb 2 o 5 Content is 2.37%, TiO 2 content 4.13%, Fe content 16.75%, rare earth oxide REO content 3.32%, CaO content 14.03%, SiO 2 Content 12.75%, MgO content 10.05%, Al 2 o 3 Content 1.87%, niobium mainly exists in niobite, niobium-iron rutile, calcite form), slagging agent (this embodiment selects limestone for use), reducing agent (this embodiment selects coke, contains C content 84%) by 100:20:4 mass ratio for mixing ingredients;

[0042] (2) Put the ingredients obtained in step (1) into the electric furnace for smelting, and smelt to produce slag and flue gas; control the smelting temperature to 1550°C, and the smelting time for 30 minut...

Embodiment 2

[0048] A method for enriching and recovering niobium, rare earth and titanium from polymetallic ores containing iron, niobium and rare earth, comprising the following steps:

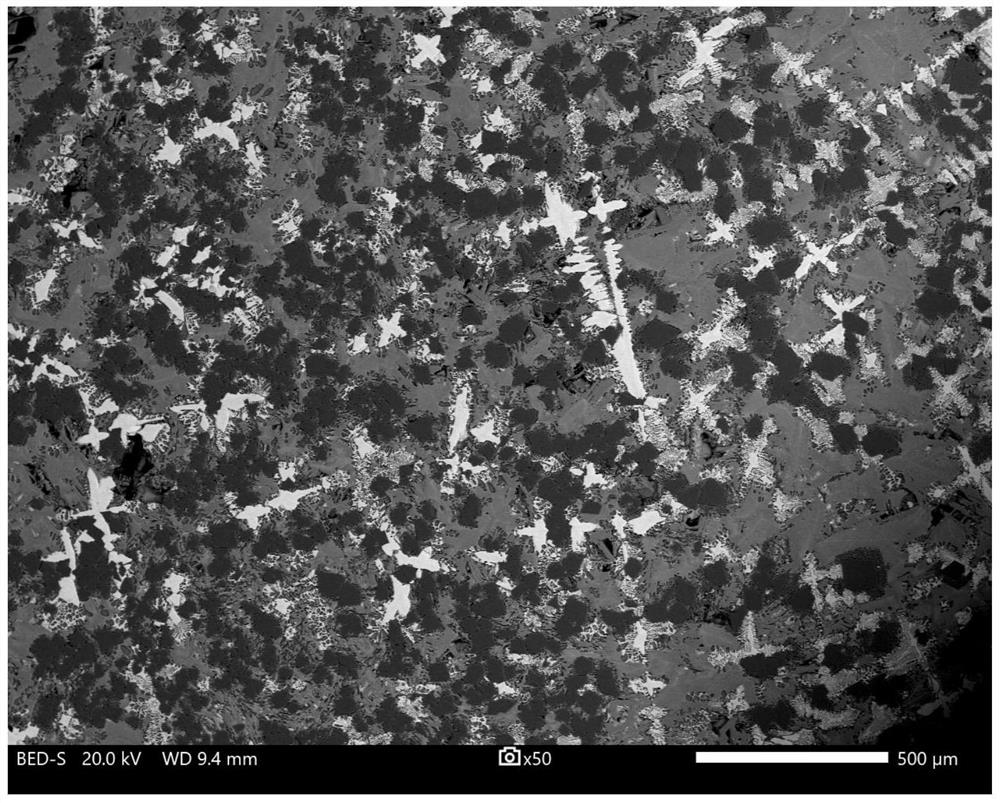

[0049] (1) Complex ore materials containing low-grade niobium / rare earth / titanium (such as iron niobium rare earth concentrate, its Nb 2 o 5 Content is 5.40%, TiO 2 content 4.29%, Fe content 35.09%, rare earth oxide REO content 4.11%, CaO content 3.91%, SiO 2 Content 20.05%, MgO content 1.17%, Al 2 o 3 content of 0.34%, niobium mainly exists in the form of niobite, niobium-iron rutile, and calcite), slagging agent (this embodiment uses a mixture of limestone and dolomite with a mass ratio of 1:1), reducing agent (this embodiment uses A mixture of anthracite and granular coal at a mass ratio of 1:0.5, with a total average C content of 79%) is mixed with a mass ratio of 100:73:15;

[0050] (2) Put the ingredients obtained in step (1) into the shaft furnace for smelting, and smelt to produce iron-conta...

Embodiment 3

[0056] A method for enriching and recovering niobium, rare earth and titanium from polymetallic ores containing iron, niobium and rare earth, comprising the following steps:

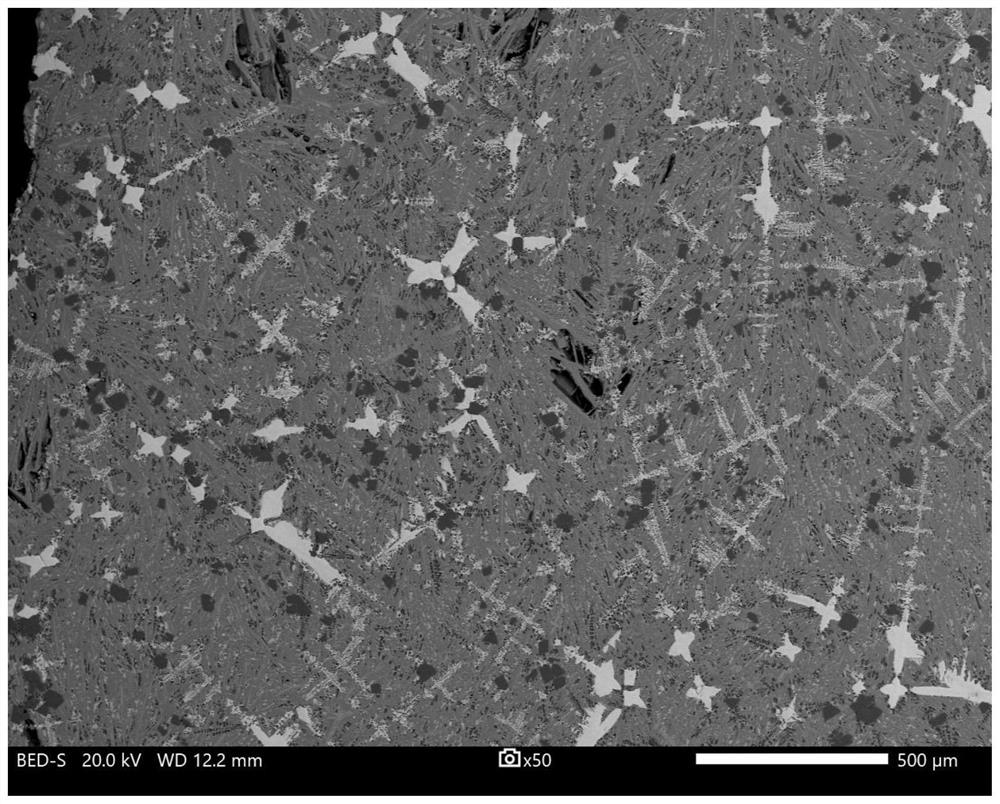

[0057] (1) Complex ore materials containing low-grade niobium / rare earth / titanium (such as ferroniobium concentrate, its Nb 2 o 5 Content is 3.52%, TiO 2 content 4.29%, Fe content 14.03%, rare earth oxide REO content 1.50%, CaO content 14.03%, SiO 2 Content 12.75%, MgO content 10.05%, Al 2 o 3 Content 1.87%, niobium mainly exists in niobite, niobium-iron rutile, calcite form), slagging agent (this embodiment selects dolomite), reducing agent (this embodiment selects pulverized coal, C content 89%) by 100:54:6 mass ratio for mixing ingredients;

[0058] (2) Put the ingredients obtained in step (1) into the converter for smelting, and smelt to produce slag and flue gas; control the smelting temperature to 1550°C, and the smelting time for 30 minutes; by controlling the composition of the ingredients i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com