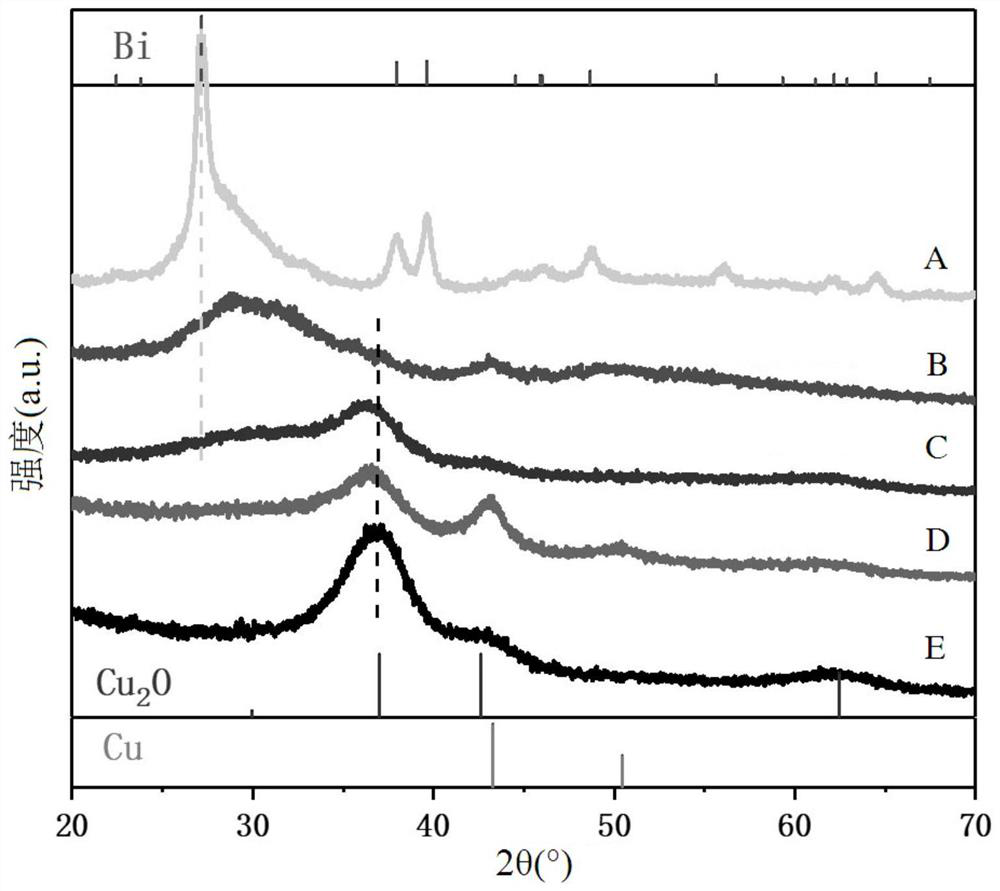

A kind of preparation method and application of nanometer cu-bi alloy catalyst

An alloy catalyst, cu-bi technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve the problems of poor stability and low product selectivity, etc. Achieve good nanostructure, improve product selectivity, inhibit the formation of ethylene and the effect of competition for hydrogen evolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

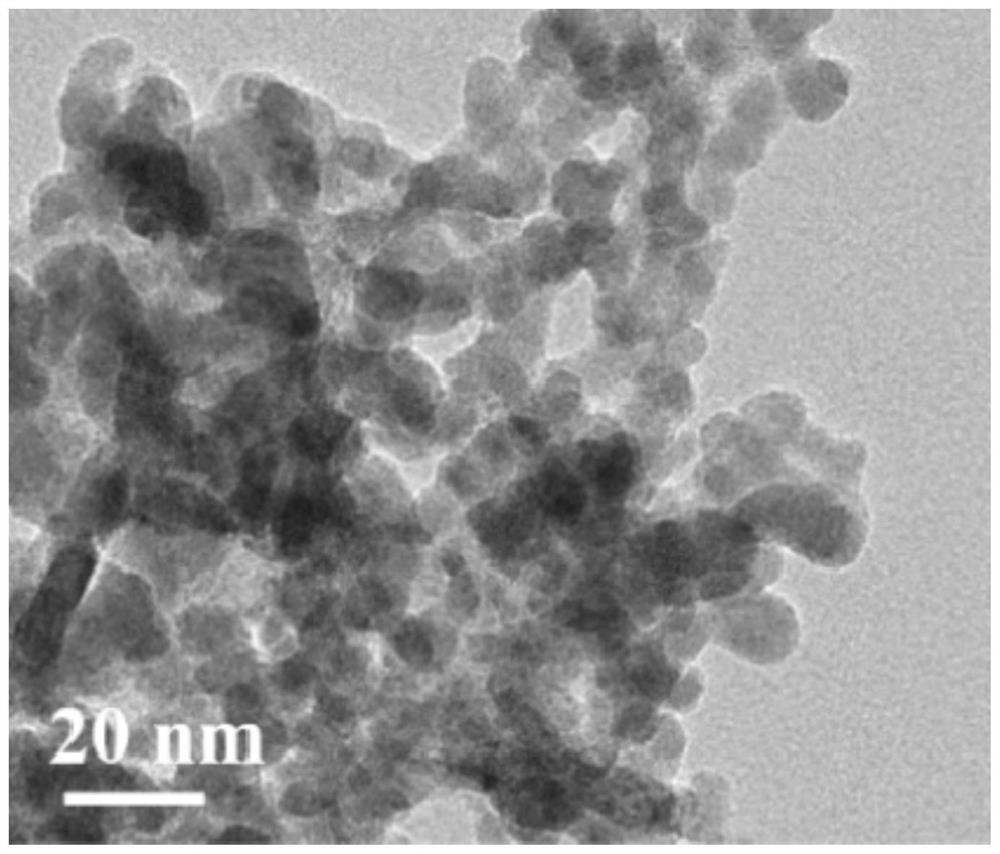

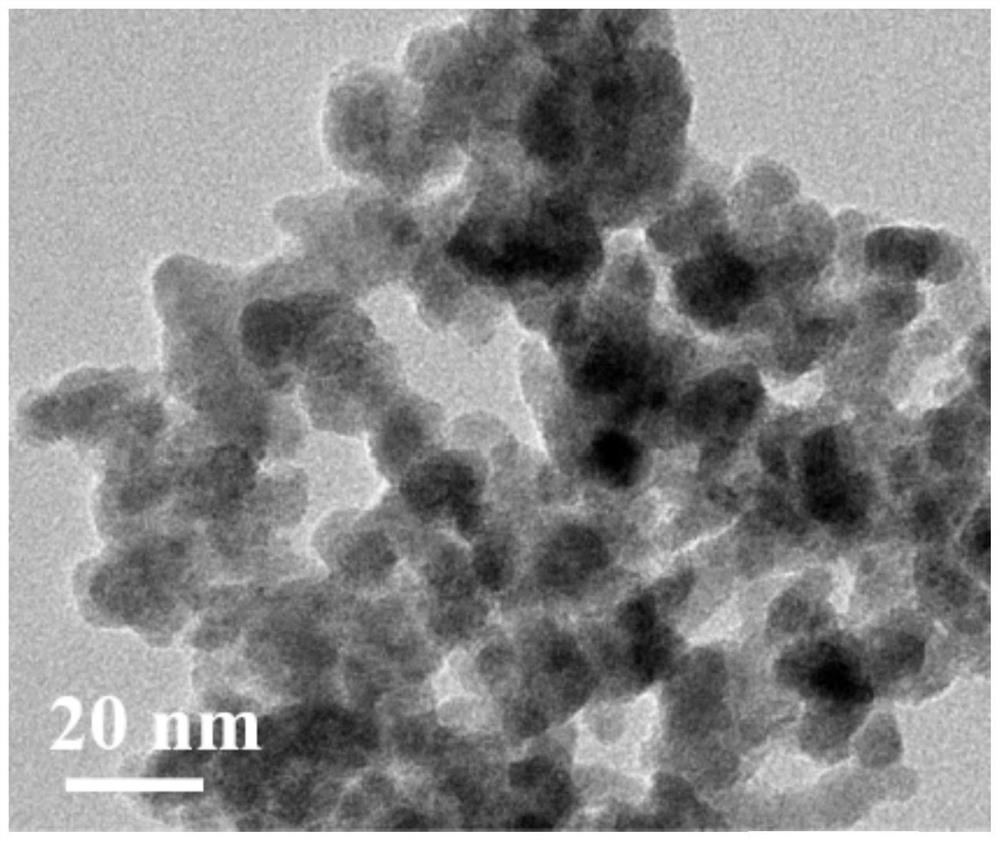

[0025] Specific embodiment one: this embodiment is a kind of preparation method of nano-Cu-Bi alloy catalyst, specifically completes according to the following steps:

[0026] 1. Preparation of precursor salt solution: dissolve the surfactant in an alcohol-containing organic solvent to obtain a surfactant-alcohol-containing organic solvent, and dissolve the copper salt and bismuth salt in the surfactant-alcohol-containing organic solvent under the protection of an inert gas. In the solvent, the precursor salt solution is obtained; the volume ratio of the amount of the surfactant to the alcohol-containing organic solvent is (0.002~2) mmol: 20mL; the copper element in the copper salt and the bismuth element in the bismuth salt The molar ratio is 1 to 9:1; the volume ratio of the sum of the amounts of copper in the copper salt and bismuth in the bismuth salt to the alcohol-containing organic solvent is (0.02 to 0.2) mmol: 20 mL;

[0027] 2. Reduction: Dissolve the reducing agent ...

specific Embodiment approach 2

[0032] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the surfactant described in step one is sodium dodecylbenzenesulfonate, PVP K30 or CTAB (hexadecyl trimethyl bromide ammonium). Others are the same as the first embodiment.

[0033] PVP-K30 is one of polyvinylpyrrolidone products with a K value of 30.

specific Embodiment approach 3

[0034] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the alcohol-containing organic solvent described in step 1 is ethylene glycol or diethylene glycol. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com