Preparation method of modified polyurethane sponge filler for emergency of MBBR process

A polyurethane sponge, polyurethane technology, applied in chemical instruments and methods, sustainable biological treatment, water/sludge/sewage treatment, etc., can solve the problem of surface wetting, poor mass transfer performance, hydrophilicity and Problems such as poor biological affinity, to achieve the effect of enhancing the effect of hanging film, improving hydrophilicity and improving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

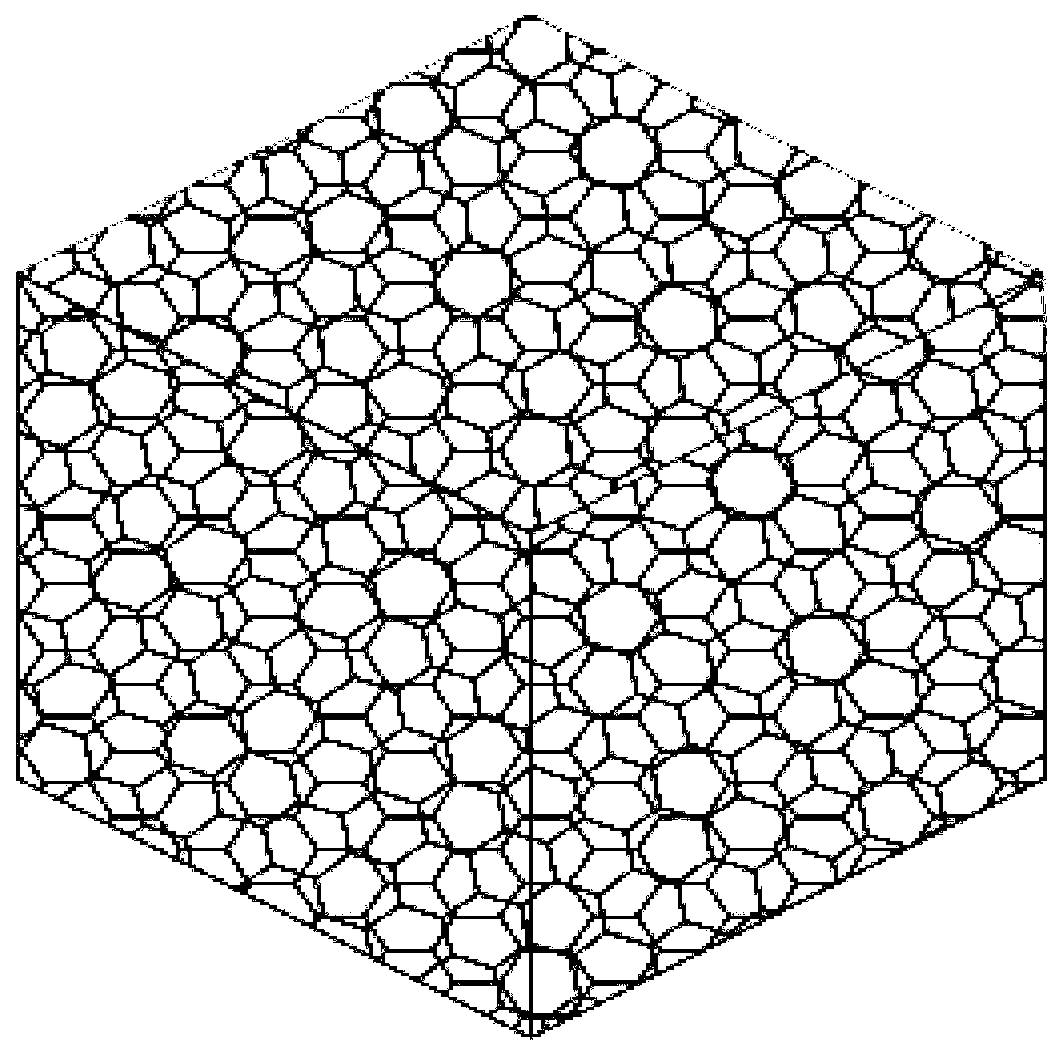

Image

Examples

preparation example Construction

[0026] See the accompanying drawings for details. The present invention adopts a preparation method of modified polyurethane sponge filler for MBBR process emergency use. The conventional polyurethane block sponge filler is modified with a modifier. After modification, the surface of the sponge filler has a certain amount of hydroxyl groups. , carbonyl and other hydrophilic groups, the specific steps are as follows:

[0027] (1) Soak the block polyurethane sponge filler in the mixed solution of acidic potassium permanganate;

[0028] (2) Take out the sponge filler and soak it in hydrochloric acid solution until the brown layer on the surface is washed away, and then take it out and drain;

[0029] (3) Put the drained sponge filler into phosphate buffered saline solution (PBS) for soaking, take out the solution and let it dry naturally after the solution is neutral;

[0030] (4) Soak the dried sponge filler in the modifier, and take it out and drain;

[0031] (5) the sponge f...

Embodiment 1

[0035] 1) Soak block polyurethane sponge packing (15mm×15mm×15mm) in 60°C acidic potassium permanganate mixed solution for 3h, the concentration of potassium permanganate is 0.2mol / L, the concentration of concentrated sulfuric acid is 2

[0036] mol / L;

[0037] 2) Take out the sponge filler and soak it in 6mol / L hydrochloric acid solution until the brown layer on the surface is washed away, then take it out and drain;

[0038] 3) Soak the drained sponge filler in 0.01mol / L PBS solution, take it out and dry naturally after the solution is neutral;

[0039] 4) Soak the dried sponge filler in 50°C, 5% acrylic acid solution for 6 hours, take it out and drain;

[0040] 5) Heat the 1g / L gelatin protein solution in a water bath to 37°C, add 16g of diatomaceous earth and 15g of powdered activated carbon into it, stir evenly, then put the drained sponge filler into the gelatin protein solution, and keep the temperature at 37°C Stirring under the conditions for 24h;

[0041] 6) Take ...

Embodiment 2

[0044] 1) Soak block polyurethane sponge packing (15mm×15mm×15mm) in 60°C acidic potassium permanganate mixed solution for 2 hours, the concentration of potassium permanganate is 0.3mol / L, and the concentration of concentrated sulfuric acid is 2mol / L;

[0045] 2) Take out the sponge filler and soak it in 5mol / L hydrochloric acid solution until the brown layer on the surface is washed away, then take it out and drain;

[0046] 3) Soak the drained sponge filler in 0.015mol / L PBS solution, take it out and dry it naturally after the solution is neutral;

[0047] 4) Soak the dried sponge filler in 50°C, 5% acrylic acid solution for 5 hours, take it out and drain;

[0048]5) Heat the 1g / L gelatin protein solution to 37°C in a water bath, add 10g diatomaceous earth and 18g powdered activated carbon into it, stir evenly, then put the drained sponge filler into the gelatin protein solution, and keep the temperature at 37°C Stirring under the conditions for 24h;

[0049] 6) Take out t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com