Preparation method of vitamin B12

A technology of B12 and vitamins, which is applied in the fields of medicine and chemical industry, can solve the problems of increasing production costs and environmental protection costs, large fluctuations in the quality of acetone crystallization, and high solvent consumption, and achieve the effects of improving resin utilization, shortening working hours, and reducing safety risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

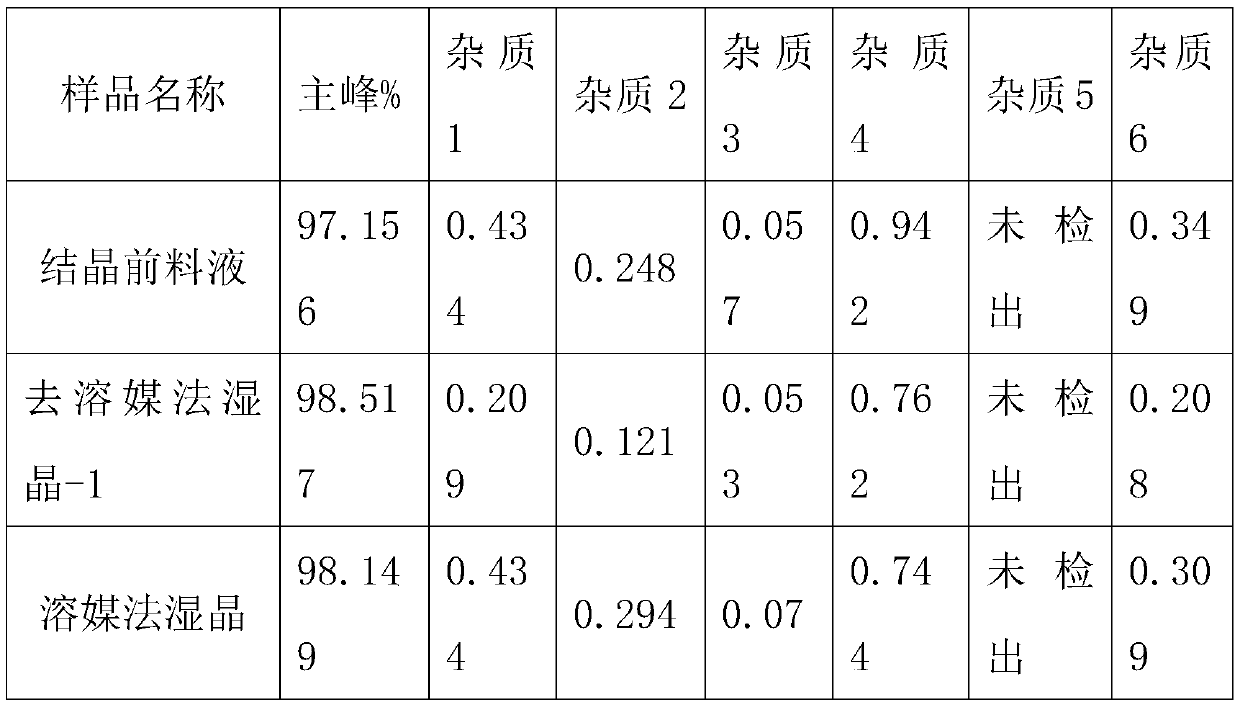

Examples

preparation example Construction

[0027] The invention discloses a preparation method of vitamin B12. The invention adopts the vitamin B12 fermented liquid to obtain the filtrate through filtration. The filtrate is absorbed, eluted and concentrated through the cation resin column, and then the conversion agent is added, and the temperature rise reaction is used to obtain the vitamin B12 conversion liquid. Then the vitamin B12 conversion solution is used as a raw material to carry out the following steps:

[0028] (1) Adsorb and wash the vitamin B12 conversion solution through the resin column at a flow rate of 0.2 to 0.7 BV / H;

[0029] (2), analyze the resin column that has adsorbed vitamin B12 with a certain concentration of resolving agent;

[0030] (3), the vitamin B12 concentrated solution analyzed in step 2 is added to a rotary evaporator for temperature-controlled concentration, and the temperature-controlled temperature is 60-70° C.;

[0031] (4), the concentrated solution of vitamin B12 after the step...

Embodiment 1

[0039] This embodiment uses above-mentioned method to prepare vitamin B12, comprises the following steps:

[0040] (1), the vitamin B12 conversion solution is adsorbed by the 288 resin column packed in 100ml at a flow rate of 0.5BV / H, and washed with water at a flow rate of 0.5BV / H after the adsorption is completed;

[0041] (2), be that the 330ml acetone resolving agent of 15% is analyzed the resin column that has adsorbed vitamin B12 with concentration;

[0042] (3), take out 1000ml of the vitamin B12 purification solution analyzed in step 2 and add it to a rotary evaporator for temperature-controlled concentration, and the temperature-controlled temperature is about 65°C;

[0043] (4), the concentrated solution of vitamin B12 after step 3 is concentrated is passed through 900 purification column with 3BV / H;

[0044] (5), adding the vitamin B12 concentrated solution purified in step 4 to the rotary evaporator again for temperature-controlled concentration, and the temperatu...

Embodiment 2

[0052] Include the following steps:

[0053] (1), the vitamin B12 conversion solution is adsorbed by the 288 resin column packed in 100ml at a flow rate of 0.5BV / H, and washed with water at a flow rate of 0.5BV / H after the adsorption is completed;

[0054] (2), be that the 330ml acetone resolving agent of 15% is analyzed the resin column that has adsorbed vitamin B12 with concentration;

[0055] (3), take out 1000ml of the vitamin B12 purification solution analyzed in step 2 and add it to a rotary evaporator for temperature-controlled concentration, and the temperature-controlled temperature is 65°C;

[0056] (4), the concentrated solution of vitamin B12 after step 3 is concentrated is passed through 900 purification column with 3BV / H;

[0057] (5), adding the vitamin B12 concentrated solution purified in step 4 to the rotary evaporator again for temperature-controlled concentration, and the temperature-controlled temperature is about 65°C;

[0058] (6), the purification sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com