Improved polyurethane foamed heat-preservation plate and preparation method thereof

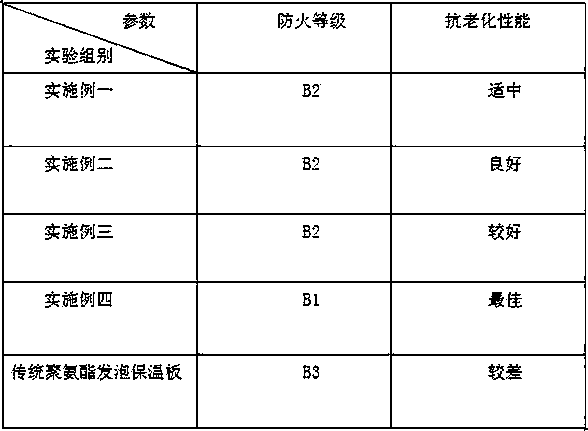

A foam insulation board and polyurethane technology, applied in the field of improved polyurethane foam insulation board and its preparation, can solve the problems of low fire protection level of foam insulation board, inability to adapt to various use occasions, easy aging and other problems, and achieve anti-aging Performance improvement, fire protection level improvement, and the effect of increasing corporate income

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The invention provides a technical solution: an improved polyurethane foam insulation board. The formula of the improved polyurethane foam insulation board includes the following components: polyurethane 25%, polystyrene 34%, methyl methyl phosphate 8 %, magnesium powder 2%, mica powder 1%, film-forming agent 2%, and the rest is solvent.

[0021] Wherein, the solvent is ethylene glycol, and the film-forming agent is acrylic acid emulsion.

[0022] An improved polyurethane foam insulation board as described above and a preparation method thereof, the preparation method comprising the following steps:

[0023] S1: Quantitative weighing, all raw materials are weighed according to the above components;

[0024] S2: Polyaddition treatment, adding the weighed polyurethane and polystyrene into the sealed container in turn, heating, the heating temperature is controlled at 85°C, and after heating for 1 hour, add dimethyl methyl phosphate to the inside of the sealed container, ...

Embodiment 2

[0029] The present invention provides a technical solution: an improved polyurethane foam insulation board, the formula of the improved polyurethane foam insulation board includes the following components: polyurethane 27%, polystyrene 32%, methyl methyl phosphate 12% %, magnesium powder 6%, mica powder 3%, film-forming agent 5%, and the rest is solvent.

[0030] Wherein, the film-forming agent is selected pure propanolactic acid, and the solvent is selected xylene.

[0031] An improved polyurethane foam insulation board as described above and a preparation method thereof, the preparation method comprising the following steps:

[0032] S1: Quantitative weighing, all raw materials are weighed according to the above components;

[0033] S2: Polyaddition treatment, add the weighed polyurethane and polystyrene into the airtight container in turn, and heat, the heating temperature is controlled at 90°C, after heating for 1.4 hours, add dimethyl methyl phosphate to the inside of th...

Embodiment 3

[0038] The invention provides a technical solution: an improved polyurethane foam insulation board. The formula of the improved polyurethane foam insulation board includes the following components: 30% polyurethane, 30% polystyrene, 10% dimethyl phosphate %, magnesium powder 3%, mica powder 5%, film-forming agent 3%, and the rest is solvent.

[0039] Wherein, the film-forming agent is selected from phenylalanine lactic acid, and the solvent is selected from the mixture of ethylene glycol and xylene.

[0040] An improved polyurethane foam insulation board as described above and a preparation method thereof, the preparation method comprising the following steps:

[0041] S1: Quantitative weighing, all raw materials are weighed according to the above components;

[0042] S2: Polyaddition treatment, adding the weighed polyurethane and polystyrene into a sealed container in turn, heating, the heating temperature is controlled between 94°C, and after heating for 1.8 hours, add dime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com