Thickened oil thermal production well sulfide removing agent and preparation method thereof

A technology for thermal recovery of heavy oil and sulfide, applied in chemical instruments and methods, separation methods, organic chemistry, etc., can solve the problems of no treatment, poor temperature resistance, poor desulfurization effect, etc., achieve less dosage and strong stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

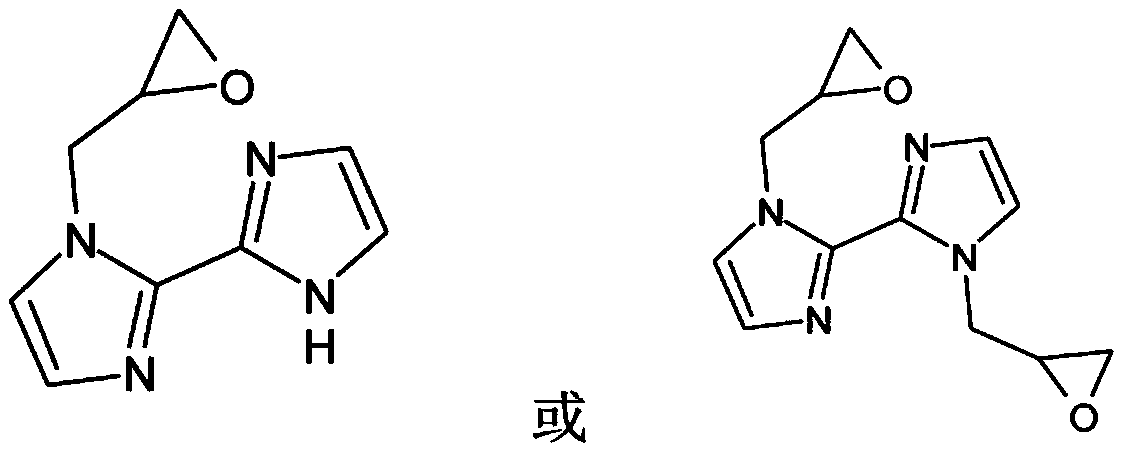

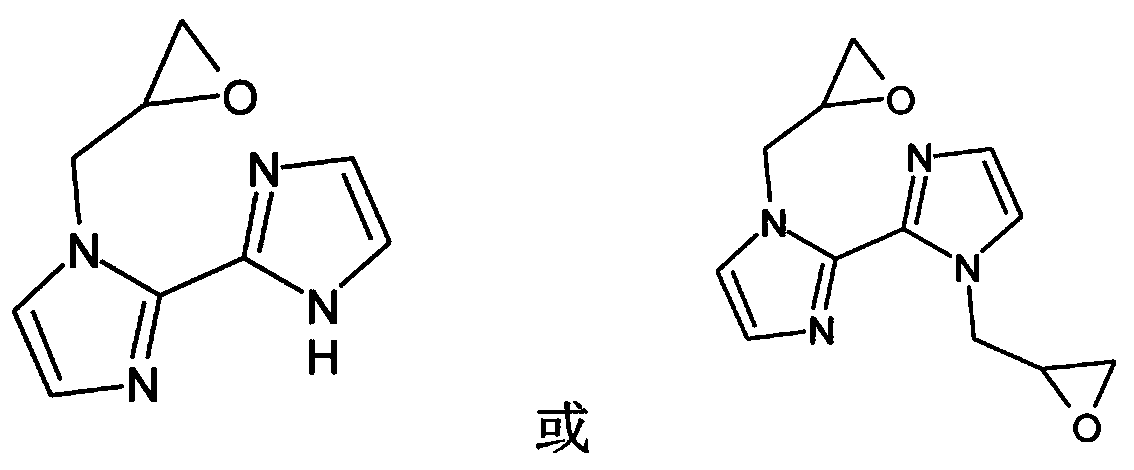

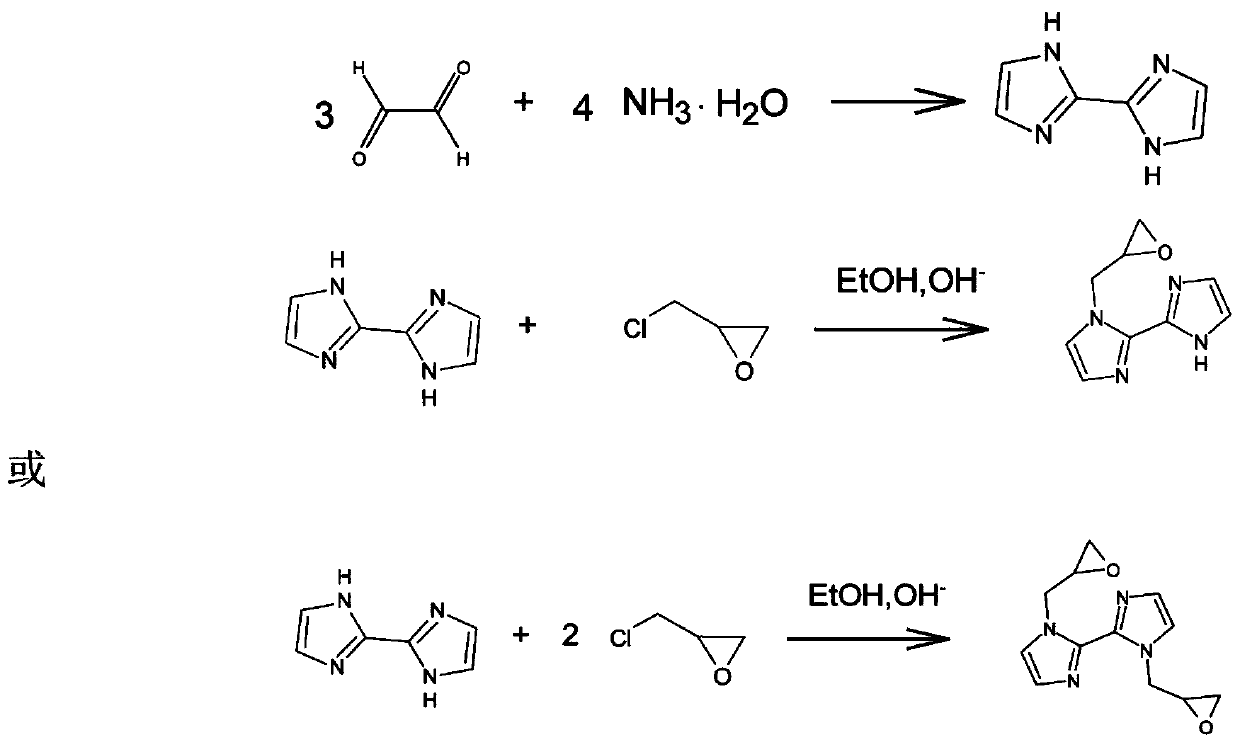

Method used

Image

Examples

Embodiment 158

[0028] Example 1 58.04

[0029] (1) Add 1 mol of glyoxal to the three-necked flask, put it into a magnetic rotor, place the three-necked flask on a constant temperature water bath with magnetic stirring, and control the temperature of the water bath at 25°C.

[0030] (2) Install 2 separating funnels on the above-mentioned three-necked flask, turn on the magnetic stirring, and the stirring rate is 120rpm.

[0031] (3) Add 4 mol of ammonium salt solution (calculated as ammonia) into the separatory funnel 1, control the dropping rate to 1 mL / min, and continue to stir and react for 0.5 h after the dropping to obtain the intermediate product biimidazole.

[0032] (4) Add 2.902 g of ethanol solution of alkali to the above-mentioned intermediate product biimidazole, add 1mol epichlorohydrin solution in separatory funnel 2, control temperature to be 70 ℃, and the drop rate of epichlorohydrin solution is 4mL / min , react while stirring after dropwise addition, the stirring speed is 200...

Embodiment 2

[0038] (1) Add 1 mol of glyoxal into the three-necked flask, put it into a magnetic rotor, place the three-necked flask on a constant temperature water bath with magnetic stirring, and control the temperature of the water bath at 30°C.

[0039] (2) Install 2 separating funnels on the above-mentioned three-neck flask, turn on the magnetic stirring, and the stirring rate is 150rpm.

[0040] (3) Add 4.6 mol of ammonium salt solution (calculated as ammonia) into the separatory funnel 1, control the dropping rate to 2 mL / min, continue to stir and react for 0.8 h after the dropping, and obtain the intermediate product biimidazole.

[0041] (4) Add 3.500 g of ethanol solution of alkali in the above-mentioned intermediate product biimidazole, add 1.5mol epichlorohydrin solution in separatory funnel 2, control temperature is 72 ℃, the rate of addition of epichlorohydrin solution is 5mL / min, react while stirring after the dropwise addition, the stirring speed is 230rpm, the reaction ti...

Embodiment 3

[0047] (1) Add 1 mol of glyoxal into the three-necked flask, put it into a magnetic rotor, place the three-necked flask on a constant temperature water bath with magnetic stirring, and control the temperature of the water bath at 35°C.

[0048] (2) Install 2 separating funnels on the above-mentioned three-necked flask, turn on the magnetic stirring, and the stirring rate is 180rpm.

[0049] (3) Add 5 mol of ammonium salt solution (calculated as ammonia) into the separatory funnel 1, control the rate of addition to 2 mL / min, continue to stir and react for 1 h after the addition, to obtain the intermediate product biimidazole.

[0050] (4) Add 4.643 g of ethanol solution of alkali to the above-mentioned intermediate product biimidazole, add 2mol epichlorohydrin solution in separatory funnel 2, control temperature to be 75 ℃, and the drop rate of epichlorohydrin solution is 6mL / min , react while stirring after dropwise addition, the stirring speed is 300rpm, the reaction time is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com