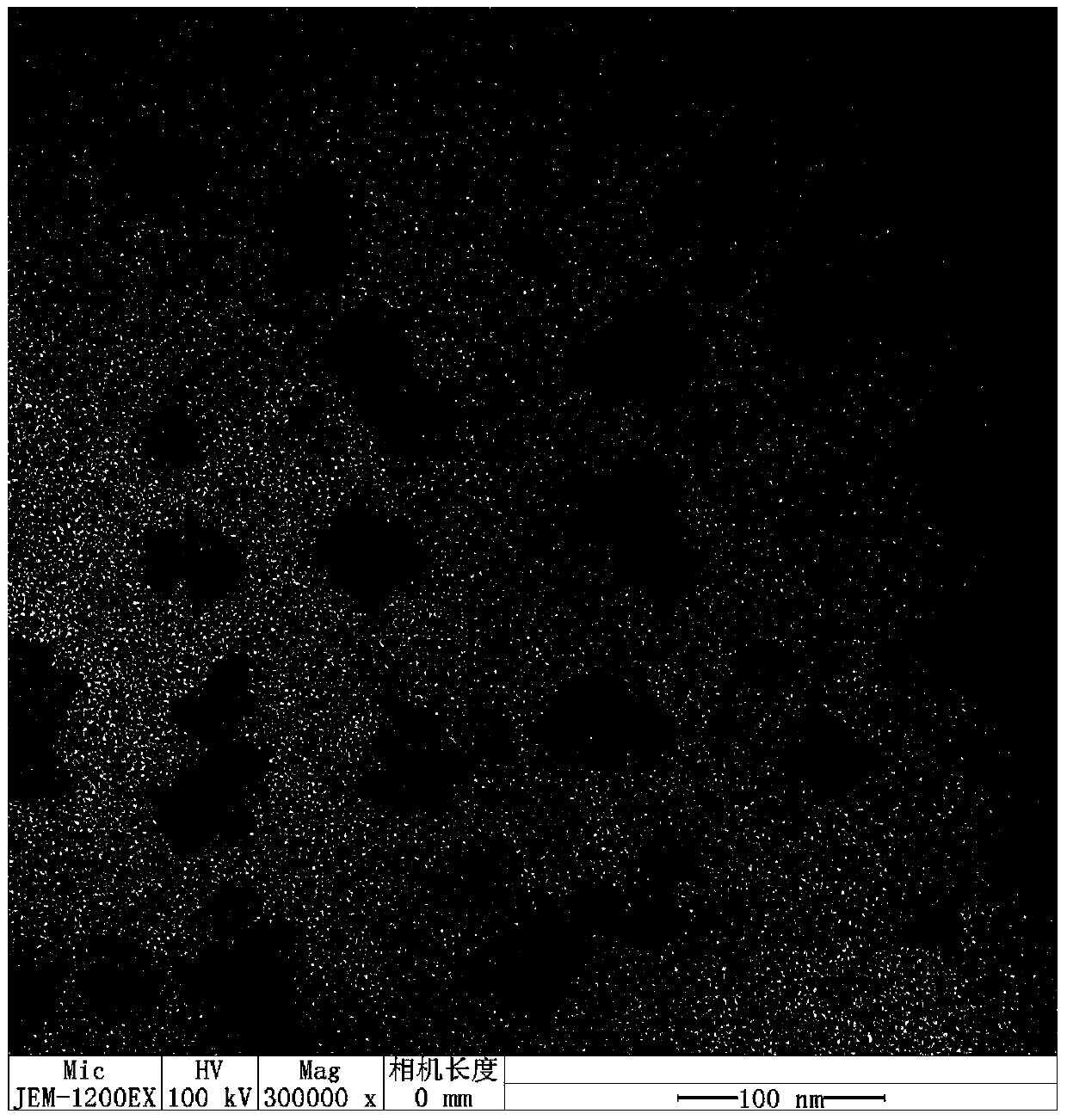

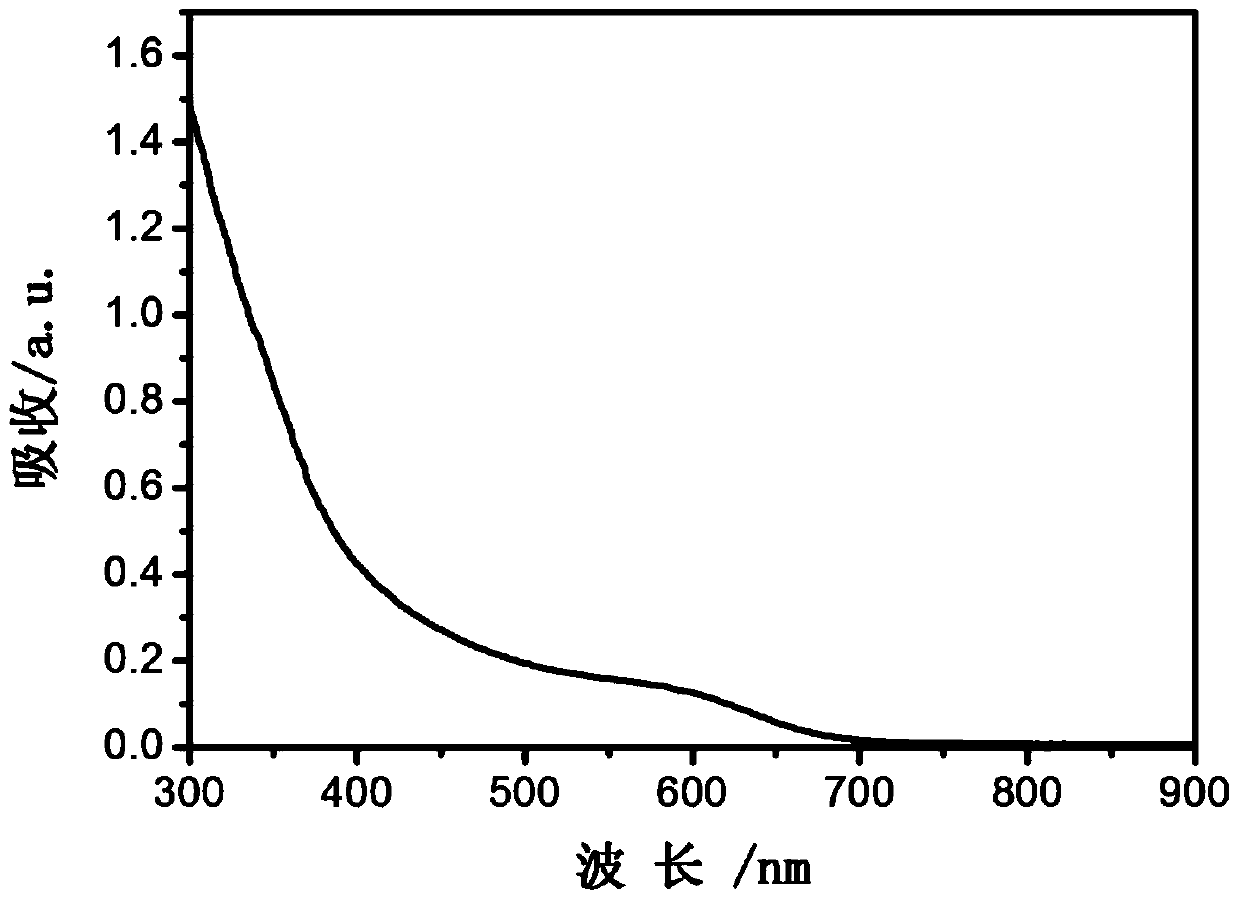

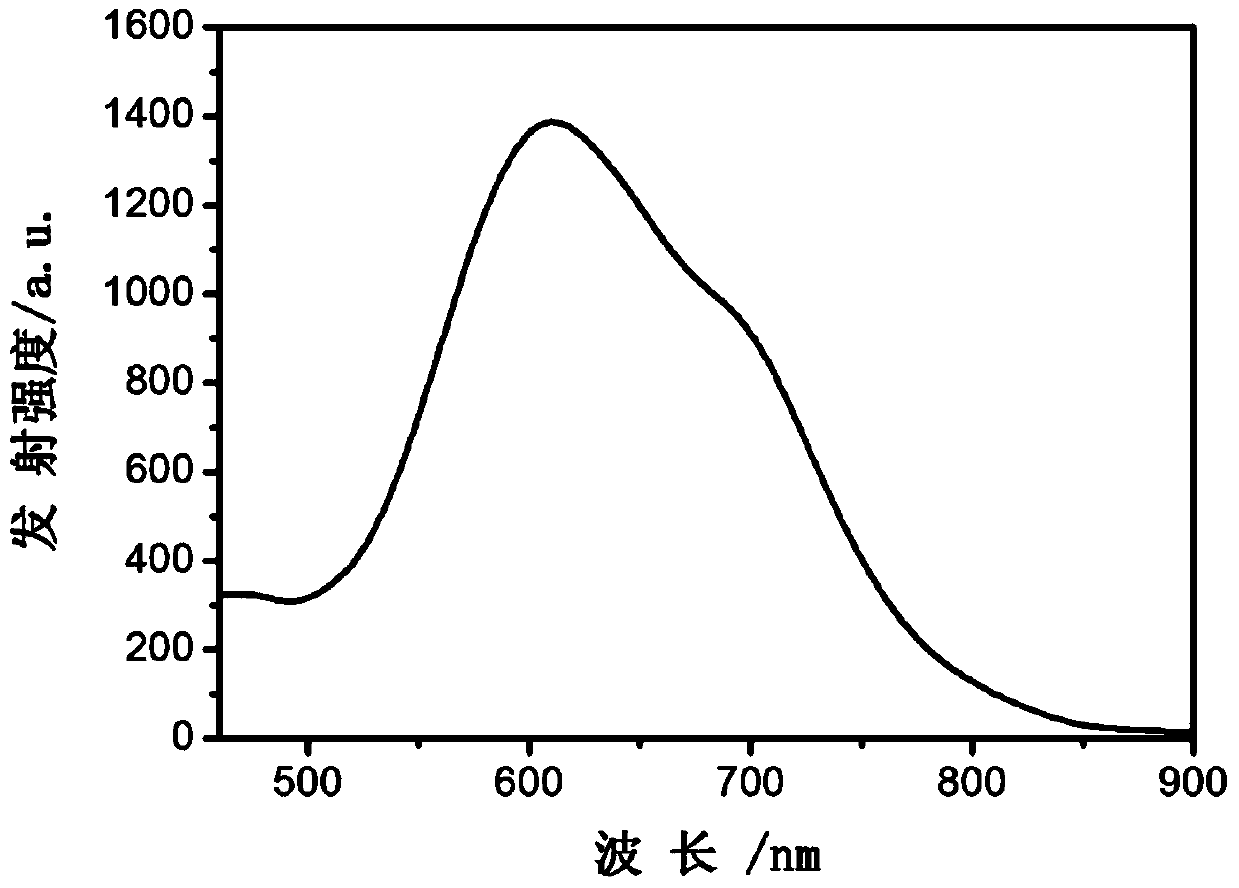

Two-dimensional Zn-Cu-In-S nanosheet and preparation method thereof

A technology of zn-cu-in-s and nanosheets, which is applied in nanotechnology, nano-optics, nanotechnology, etc., can solve the problems of application limitations, easy surface contamination, etc., and achieve the effect of excellent luminous performance and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Put 0.06mmol of indium trichloride tetrahydrate, 3ml of oleylamine and 3ml of octadecene into a three-necked flask, put the high-temperature rotor into the three-necked flask, vacuumize at room temperature for 10min, and start stirring and heating, keeping the heating rate at 5°C / min. When the temperature reaches 100°C, stop heating and turn off the vacuum pump, add nitrogen gas into the three-necked flask, stop heating and cool down to room temperature after the indium source is completely dissolved. At the same time, 0.15 mmol of sulfur source and 3 ml of octadecene were placed in a test tube, and the solution was heated under nitrogen protection. After completely dissolving, it was mixed with the indium source solution, and the mixed solution was heated at a heating rate of 5°C / min. When the temperature of the solution reaches 120° C., the copper precursor solution is added to the mixed solution, and the temperature is lowered after 3 minutes of reaction, and the co...

Embodiment 2

[0051] Put 0.04 mmol of indium trichloride tetrahydrate, 3 ml of oleylamine and 3 ml of octadecene into a three-necked flask, put the high-temperature rotor into the three-necked flask, vacuumize at room temperature for 10 minutes, and start stirring and heating, keeping the heating rate at 5°C / min. When the temperature reaches 100°C, stop heating and turn off the vacuum pump, add nitrogen gas into the three-necked flask, stop heating and cool down to room temperature after the indium source is completely dissolved. At the same time, 0.15 mmol of sulfur source and 3 ml of octadecene were placed in a test tube, and the solution was heated under nitrogen protection. After completely dissolving, it was mixed with the indium source solution, and the mixed solution was heated at a heating rate of 5°C / min. When the temperature of the solution reaches 120° C., the copper precursor solution is added to the mixed solution, and the temperature is lowered after 3 minutes of reaction, an...

Embodiment 3

[0054] Put 0.02mmol of indium trichloride tetrahydrate, 3ml of oleylamine and 3ml of octadecene into a three-necked flask, put the high-temperature rotor into the three-necked flask, vacuumize at room temperature for 10min, and start stirring and heating, keeping the heating rate at 5°C / min. When the temperature reaches 100°C, stop heating and turn off the vacuum pump, add nitrogen gas into the three-necked flask, stop heating and cool down to room temperature after the indium source is completely dissolved. At the same time, 0.15 mmol of sulfur source and 3 ml of octadecene were placed in a test tube, and the solution was heated under nitrogen protection. After completely dissolving, it was mixed with the indium source solution, and the mixed solution was heated at a heating rate of 5°C / min. When the temperature of the solution reaches 120° C., the copper precursor solution is added to the mixed solution, and the temperature is lowered after 3 minutes of reaction, and the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com