Ti3AlC2-Fe alloy-based high-temperature-resistant self-lubricating composite material and preparation method thereof

A composite material and high-temperature-resistant technology, which is applied in metal processing equipment, transportation and packaging, etc., can solve serious wear and tear problems, achieve good mechanical properties, reduce friction coefficient and wear rate, and fast sintering speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

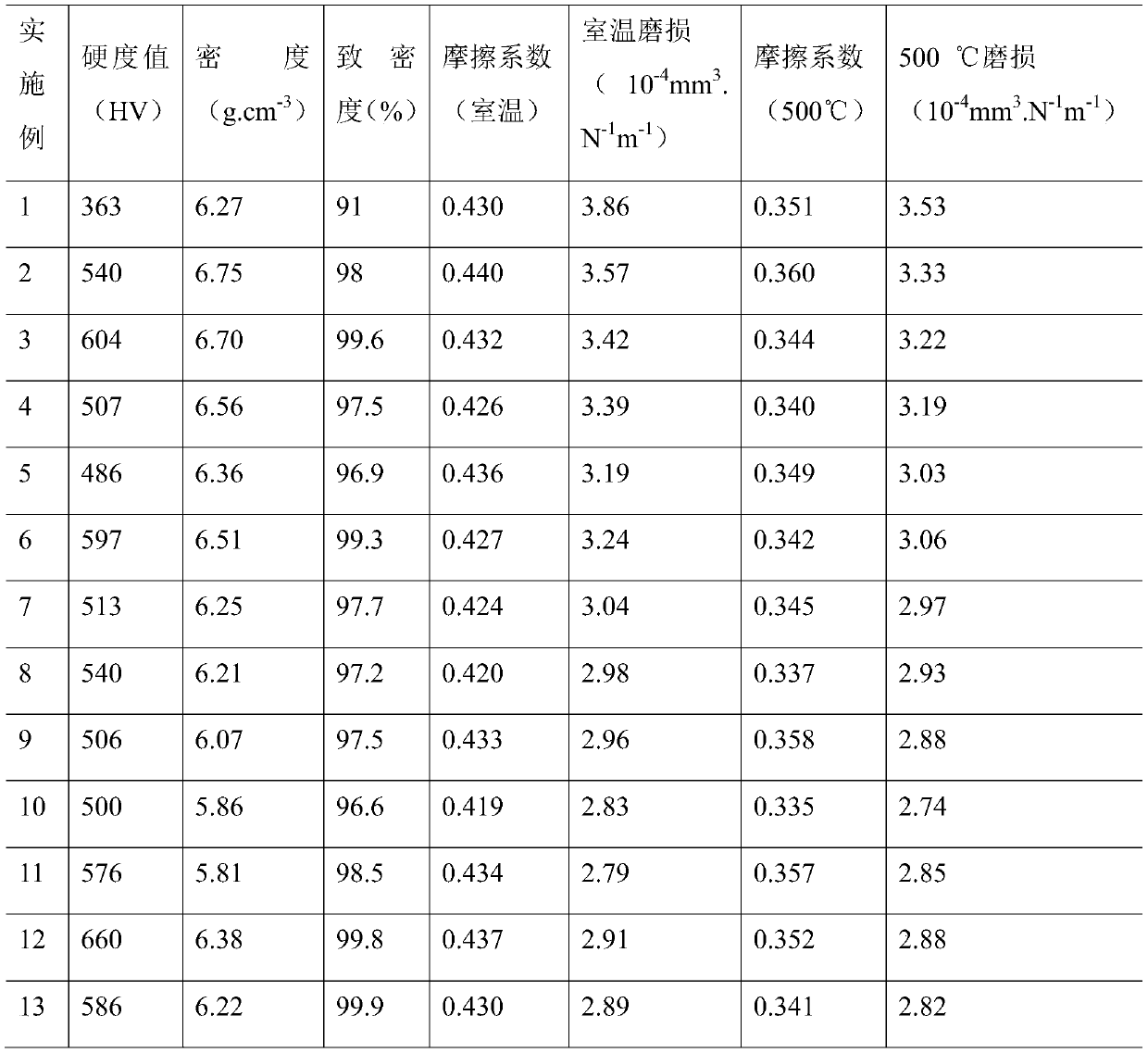

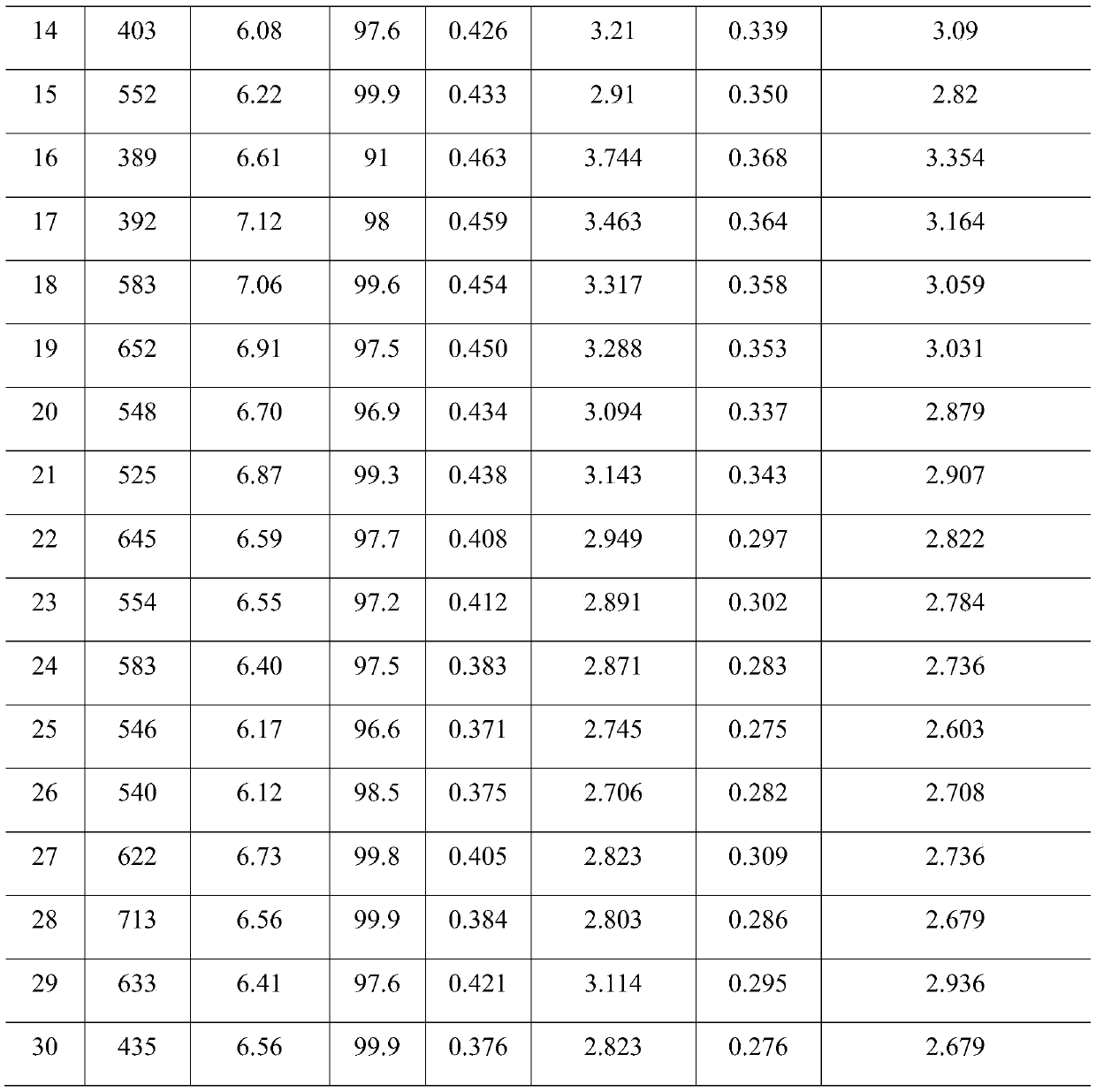

Examples

Embodiment 1

[0026] This embodiment provides a Ti 3 AlC 2 -Fe alloy-based high temperature resistant self-lubricating composite material, the preparation method of which is:

[0027] According to the volume percentage, add 5% Ti with a particle size of 40 mesh 3 AlC2 , and the rest are mixed Fe alloy powders with a particle size greater than 150 meshes. The volume percentage of the Fe alloy powder components is 15% Cu powder, 1% Ni powder, 5% Cr powder, and the rest is Fe powder. The above powders are processed by a planetary ball mill Carry out uniform ball mixing. The mixing process is carried out in an argon atmosphere. Alcohol is used as a dispersant. The amount added is 4ml per 100g of mixed powder. , running alternately in forward and reverse directions, once every 30 minutes; after drying the uniformly mixed powder, put it into a cylindrical mold for pre-compression molding, the pressure is 15MPa, the holding time is 15s, and then the pre-pressed block is dried; The dried pre-pre...

Embodiment 2

[0029] This embodiment provides a Ti 3 AlC 2 -Fe alloy-based high temperature resistant self-lubricating composite material, the preparation method of which is:

[0030] Add 10% Ti with particle size of 100 mesh according to volume percentage 3 AlC 2 , and the rest are mixed Fe alloy powders with a particle size greater than 150 meshes. The volume percentage of the Fe alloy powder components is 15% Cu powder, 1% Ni powder, 5% Cr powder, and the rest is Fe powder. The above powders are processed by a planetary ball mill Carry out uniform ball mixing. The mixing process is carried out in an argon atmosphere. Alcohol is used as a dispersant. The amount added is 5ml per 100g of mixed powder, the ball-to-material ratio is 4:1, the speed of the ball mill is set to 350r / min, and the ball milling time is 1h , running alternately in forward and reverse directions, once every 30 minutes; after drying the uniformly mixed powder, put it into a cylindrical mold for pre-compression moldi...

Embodiment 3

[0032] This embodiment provides a Ti 3 AlC 2 -Fe alloy-based high temperature resistant self-lubricating composite material, the preparation method of which is:

[0033] According to the volume percentage, add 15% Ti with a particle size of 30 mesh 3 AlC 2 , and the rest are mixed Fe alloy powders with a particle size greater than 150 meshes. The volume percentage of Fe alloy powder components is 15% Cu powder, 2% Ni powder, 3% Cr powder, and the rest is Fe powder. The above powders are processed by a planetary ball mill Carry out uniform ball mixing. The mixing process is carried out in an argon atmosphere. Alcohol is used as a dispersant. The amount added is 6ml per 100g of mixed powder, the ball-to-material ratio is 4:1, the ball mill speed is set to 300r / min, and the ball milling time is 1h , running alternately in forward and reverse directions, once every 30 minutes; after drying the uniformly mixed powder, put it into a cylindrical mold for pre-compression molding, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com