Preparation method of a two-dimensional tungsten sulfide-based vertical heterostructure material

A heterogeneous structure, tungsten sulfide technology, applied in metal material coating process, vacuum evaporation plating, coating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

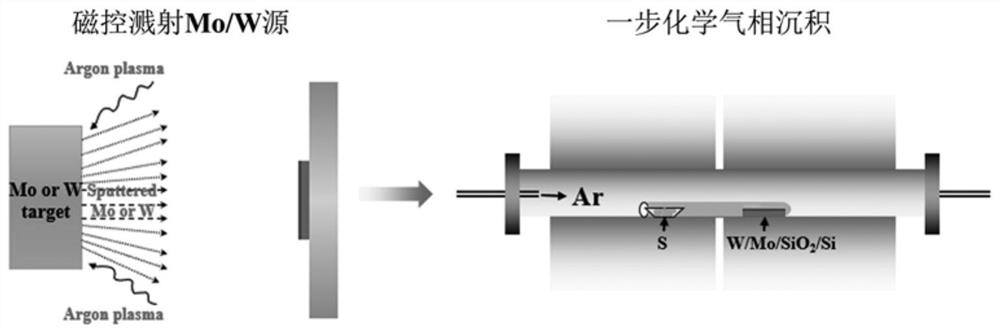

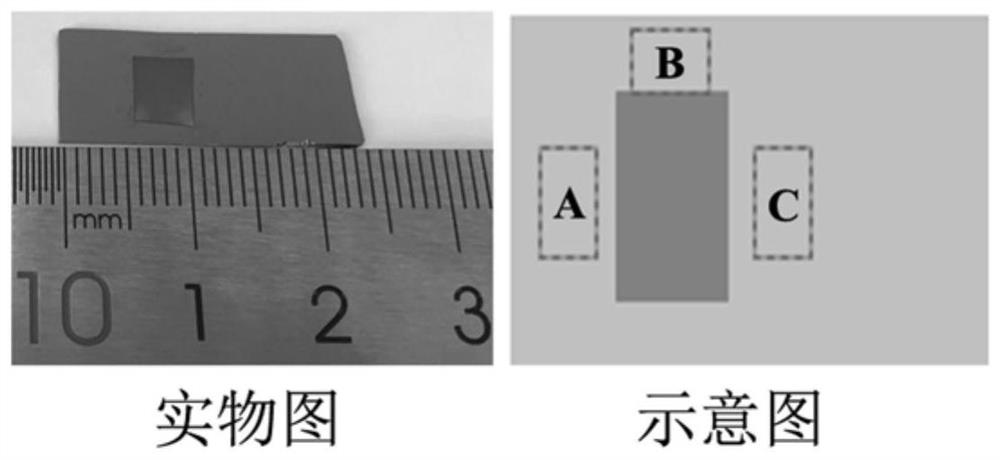

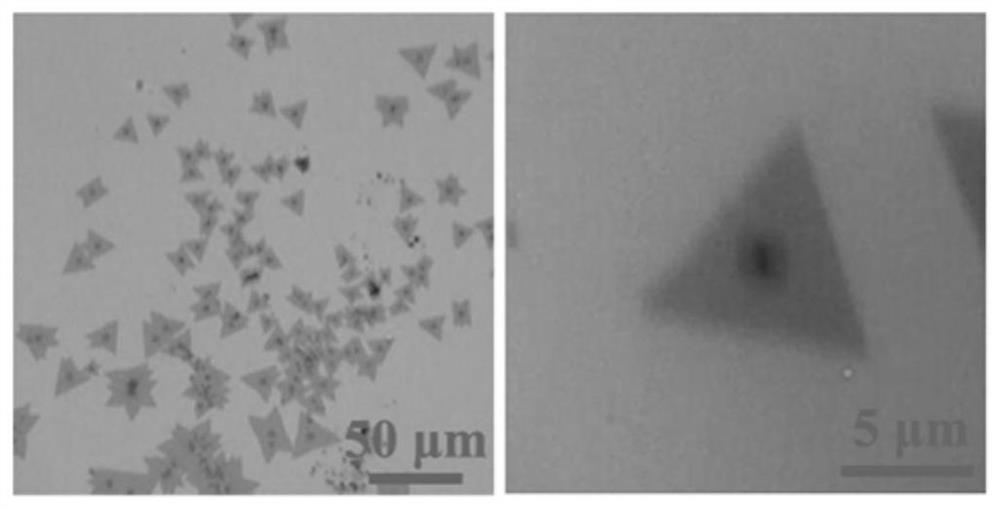

[0056] A WS 2 Two-dimensional vertical heterostructure based on Si / SiO 2 In order to deposit the substrate, the Mo / W film by magnetron sputtering is prepared by reacting Mo and W sources with sulfur source S powder. Its preparation is carried out in a double-temperature zone horizontal tube furnace, and the schematic diagram of the device is shown in figure 1 Shown, specifically comprise following preparation steps:

[0057] (1) Select Si / SiO that does not contain catalyst and seed layer 2 Substrate, the size of the substrate is 1cm×2.5cm, Si / SiO 2 The substrate is immersed in acetone solution for 10-15 minutes, then ultrasonically cleaned in ethanol solution for 10-15 minutes, then rinsed with deionized water for 3-5 times, then dried with high-purity nitrogen, and finally placed in an oven at 100°C Keep warm for 1 hour and dry for later use;

[0058] (2) if figure 1 As shown in the left figure, first in Si / SiO 2 Magnetron sputtering Mo film on one end of the substrate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com