A limit structure for intelligent printing machine

A limiting structure and technology of printing presses, applied in printing presses, general parts of printing machinery, printing and other directions, can solve the problems of general positioning effect of substrates, difficult to meet requirements, etc., and achieve difficult displacement, good integrity, and fit. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

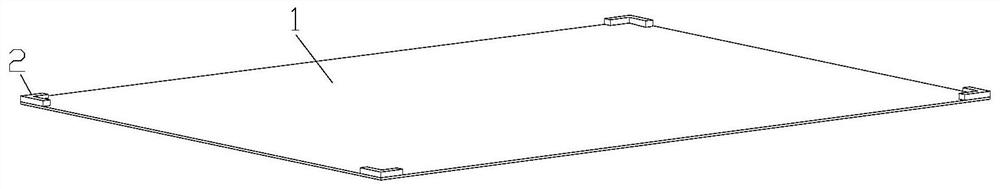

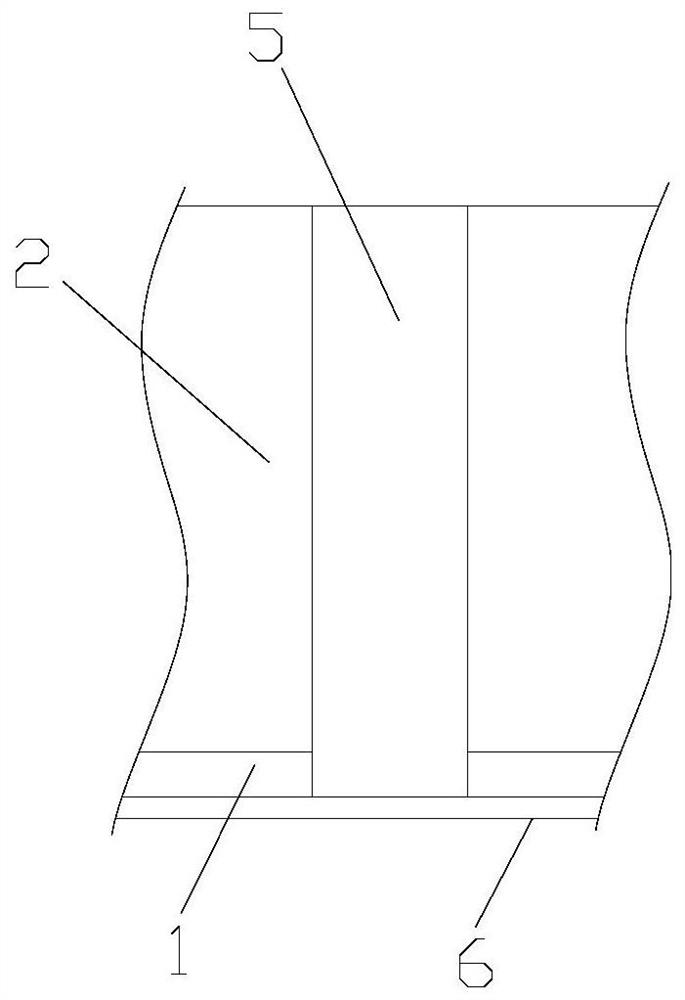

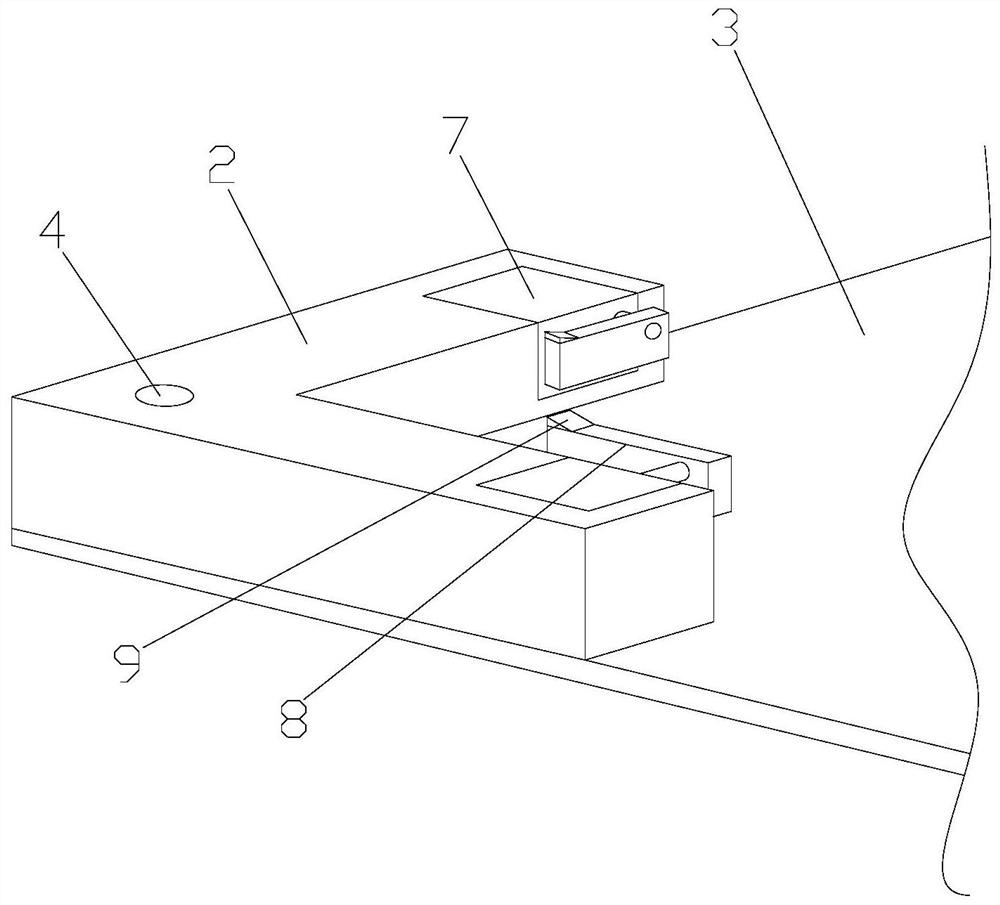

[0044] Such as Figure 1-4 As shown, a limiting structure for an intelligent printing machine includes an electrostatic adsorption film 1 for installation on a conveyor belt, and limit blocks 2 are arranged at four corners of the electrostatic adsorption film 1, and the limiting The positioning block 2 is arranged in an L shape, and the limiting block 2 is fixedly connected with the electrostatic adsorption film 1. Both ends of the limiting block 2 are provided with clamping devices for clamping the substrate. The electrostatic adsorption film 1 and the limit block 2 form a placement groove 3 that fits with the substrate, and the electrostatic adsorption film is composed of 130 parts of polyvinyl chloride resin, 45 parts of polytetrafluoroethylene, and dioctyl phthalate in proportions by weight. 2 parts, 7 parts of ethyl cellulose, 3 parts of epoxidized soybean oil, 5 parts of barium titanate, 1 part of 2-hydroxypropyl acrylate, 6 parts of hydrotalcite, 5 parts of paraffin, 1 ...

Embodiment 2

[0056] Such as Figure 1-4 As shown, a limiting structure for an intelligent printing machine includes an electrostatic adsorption film 1 for installation on a conveyor belt, and limit blocks 2 are arranged at four corners of the electrostatic adsorption film 1, and the limiting The positioning block 2 is arranged in an L shape, and the limiting block 2 is fixedly connected with the electrostatic adsorption film 1. Both ends of the limiting block 2 are provided with clamping devices for clamping the substrate. The electrostatic adsorption film 1 and the limit block 2 form a placement groove 3 that fits with the substrate, and the electrostatic adsorption film is composed of 150 parts of polyvinyl chloride resin, 65 parts of polytetrafluoroethylene, and dioctyl phthalate in proportions by weight. 4 parts, 10 parts of ethyl cellulose, 5 parts of epoxidized soybean oil, 7 parts of barium titanate, 3 parts of 2-hydroxypropyl acrylate, 8 parts of hydrotalcite, 7 parts of paraffin w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com