Rare earth element-containing ultra-supercritical steam turbine blade steel and preparation method thereof

A technology of steam turbine blades and rare earth elements, which is applied in the field of steel, can solve the problems of reducing forgeability and increasing heat strength, and achieve the effect of increasing thermoplasticity and good forgeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

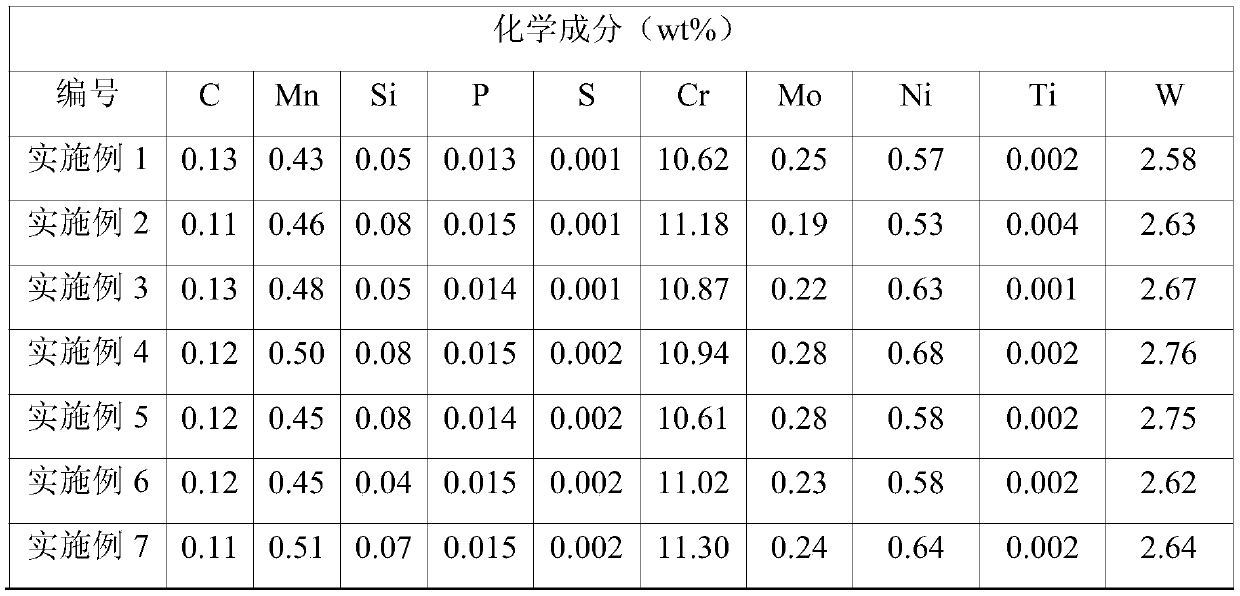

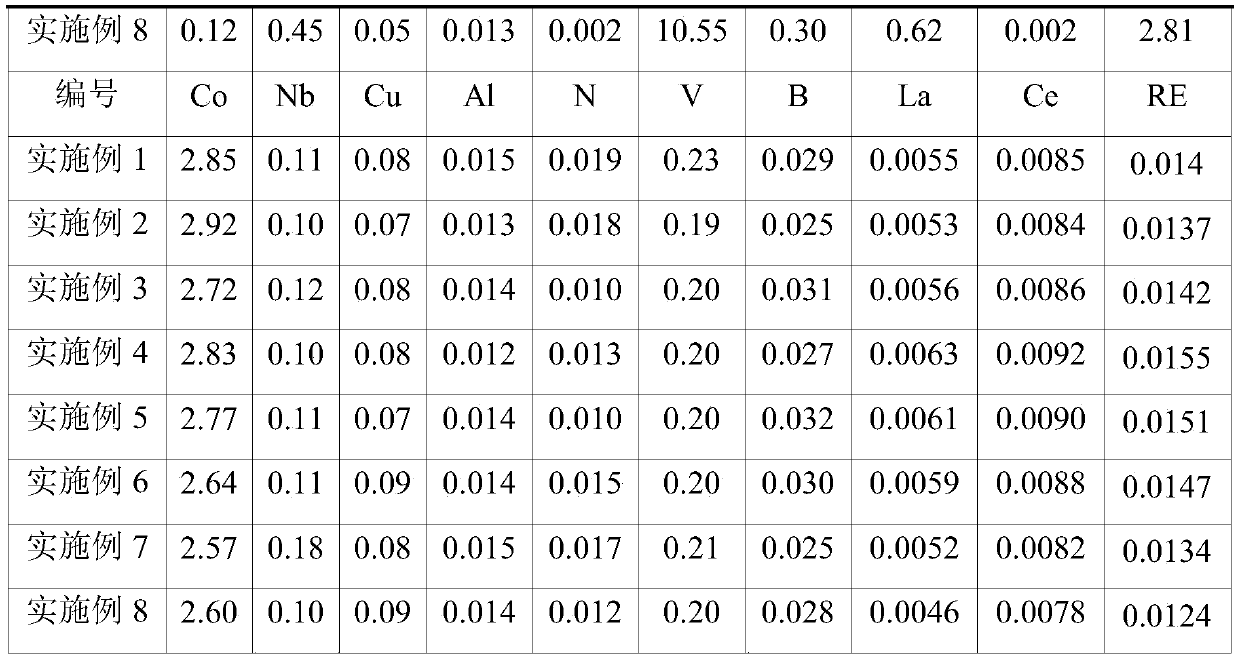

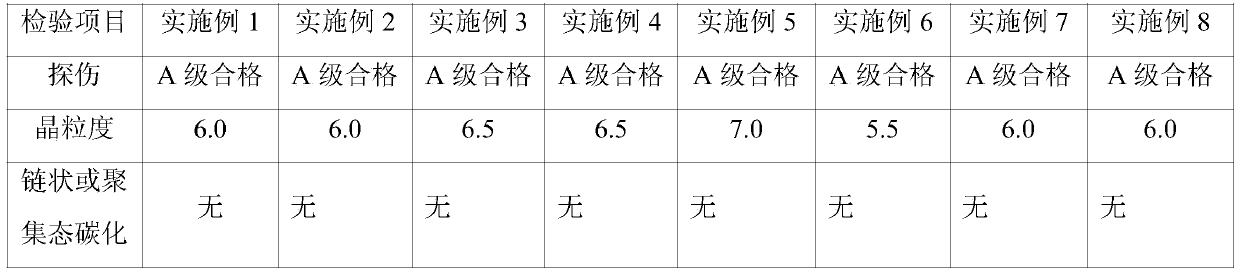

[0026] The composition of the ultra-supercritical steam turbine blade steel of table 1 embodiment 1~8

[0027]

[0028]

[0029] The specific manufacturing method of the above-mentioned ultra-supercritical steam turbine blade steel is as follows:

[0030] 1. Smelting: Refining and smelting other components except rare earth elements in electric furnace and outside the furnace, adding rare earth elements before tapping and casting, and controlling the casting temperature at 1520-1600°C to obtain electrode rods; the electrode rods are smelted by electroslag remelting process Form an electroslag ingot of Φ400~550mm.

[0031] 2. Electroslag ingot blanking: Forging blanking is adopted, the heating temperature is 1150-1170°C, the initial forging temperature of blank opening is 1050-1150°C, and the final forging temperature is >850°C.

[0032] 3. Precision forging forming: the blank heating temperature is 1150-1170°C, the start precision forging temperature is ≥950°C, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com