A liquid crystal display component heating method under low temperature and low pressure environment

A liquid crystal display, low pressure technology, applied in temperature control, instruments, optics, etc., can solve the problems of high heating power consumption and poor heating reliability, and achieve the effect of reducing heating power consumption, improving heating efficiency, and improving heating reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

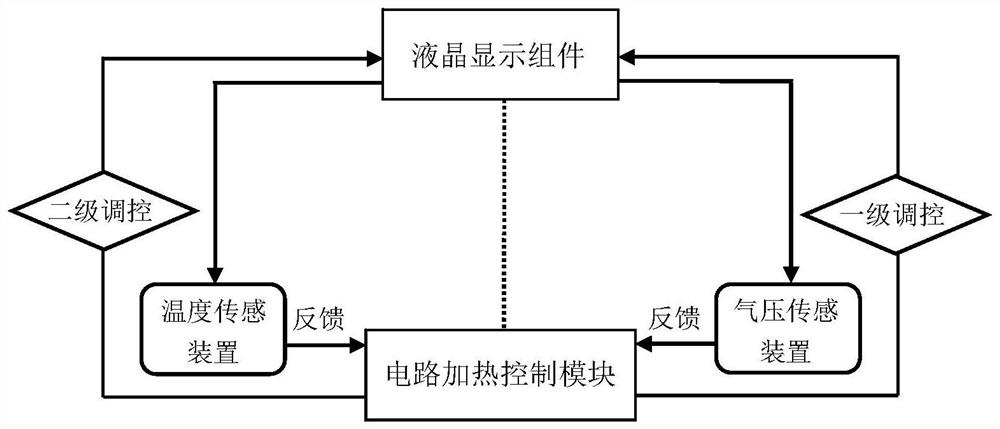

[0024] like figure 1 shown.

[0025] A method for heating a liquid crystal display assembly in a low temperature and low pressure environment. For the liquid crystal display assembly heated behind the screen, an air pressure sensing device and a temperature sensing device are simultaneously arranged inside the liquid crystal display assembly, and the air pressure sensing device is used to detect the ambient air pressure value. Change and feed back to the circuit heating control module for first-level regulation of heating power consumption. The temperature sensing device monitors the screen temperature in real time, and feeds back to the circuit heating control module for second-level dynamic regulation of heating power consumption.

[0026] Now it is required that a certain liquid crystal display component can work normally under the low temperature and low pressure environment of -45°C and 57.33KPa. The design value of heating power consumption under normal pressure environm...

Embodiment 2

[0028] like figure 1 shown.

[0029] A method for heating a liquid crystal display assembly in a low temperature and low pressure environment. For the liquid crystal display assembly heated behind the screen, an air pressure sensing device and a temperature sensing device are simultaneously arranged inside the liquid crystal display assembly, and the air pressure sensing device is used to detect the ambient air pressure value. Change and feed back to the circuit heating control module for first-level regulation of heating power consumption. The temperature sensing device monitors the screen temperature in real time, and feeds back to the circuit heating control module for second-level dynamic regulation of heating power consumption.

[0030] Now it is required that a certain liquid crystal display component can work normally under the low temperature and low pressure environment of -40°C and 30.1KPa. The design value of heating power consumption under normal pressure environme...

Embodiment 3

[0032] like figure 1 shown.

[0033] A method for heating a liquid crystal display assembly in a low temperature and low pressure environment. For a liquid crystal display assembly heated behind a screen, an air pressure sensing device and a temperature sensing device are simultaneously arranged inside the liquid crystal display assembly, and the air pressure sensing device is used to detect the ambient air pressure value. Change and feed back to the circuit heating control module for first-level regulation of heating power consumption. The temperature sensing device monitors the screen temperature in real time, and feeds back to the circuit heating control module for second-level dynamic regulation of heating power consumption.

[0034] Now it is required that a certain liquid crystal display component can work normally under the low temperature and low pressure environment of -45°C and 69.65KPa. The design value of heating power consumption in the normal pressure environment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com