Polyvinylidene fluoride-hexafluoropropylene/cellulose/titanium dioxide composite membrane and preparation method and application thereof

A technology of polyvinylidene fluoride and titanium dioxide, which is applied in the field of lithium battery separators, can solve the problems of poor electrolyte affinity, low porosity, and poor heat resistance, and achieve enhanced affinity, high porosity, and improved heat resistance sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] In the present invention, the preparation method of the carboxy-modified titanium dioxide nanofiber preferably comprises the following steps:

[0033] Titanium dioxide nanofibers and citric acid are mixed and ground, dispersed in water, and then centrifuged to obtain carboxyl-modified titanium dioxide nanofibers.

[0034] The invention mixes and grinds titanium dioxide nanofibers and citric acid to obtain a mixture of titanium dioxide nanofibers and citric acid. In the present invention, the mixed grinding can make the titanium dioxide nanofibers and citric acid mix more uniformly.

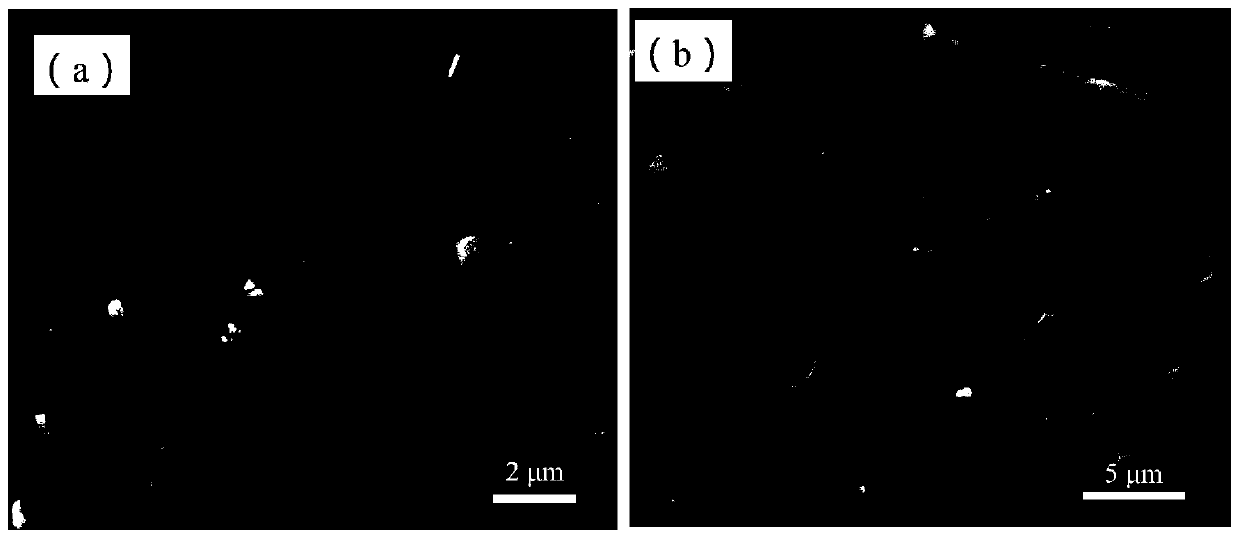

[0035] In the present invention, the diameter of the titanium dioxide nanofiber is preferably 100-300 nm; the length is preferably 1-100 μm. In the present invention, the titanium dioxide nanofibers of the above specifications are conducive to uniform dispersion in polyvinylidene fluoride-hexafluoropropylene.

[0036] In the present invention, the mass ratio of the titanium dioxide nanofi...

Embodiment 1

[0059] (1) Mix ethanol, acetic acid and tetrabutyl titanate according to the mass ratio of 10:4:3, stir magnetically at room temperature for 2 hours, then add polyvinylpyrrolidone, the concentration of polyvinylpyrrolidone is 0.045g / mL, Stir until the polyvinylpyrrolidone is completely dissolved to obtain a titanium dioxide precursor solution, then obtain a titanium dioxide nanofiber precursor by electrospinning, and calcinate the titanium dioxide nanofiber precursor at 550 ° C for 2 hours to obtain titanium dioxide nanofibers, the titanium dioxide nanofibers The diameter is 100-300nm, and the length is 1-100μm;

[0060] (2) After mixing and grinding titanium dioxide nanofibers and citric acid according to a ratio of 1:1 by mass, they were dispersed in water, stirred for 2 hours, and then centrifuged at 10,000 rpm for 5 minutes to obtain carboxyl-modified titanium dioxide nanofibers;

[0061] (3) adding the carboxyl-modified titanium dioxide nanofibers into the N-methylpyrroli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com