Membrane module and method for detecting deposits in a membrane module

A membrane module and sediment technology, applied in chemical instruments and methods, membranes, membrane technology, etc., can solve problems such as long downtime, consumption of cleaning and flushing solutions, and decreased separation efficiency of membrane modules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

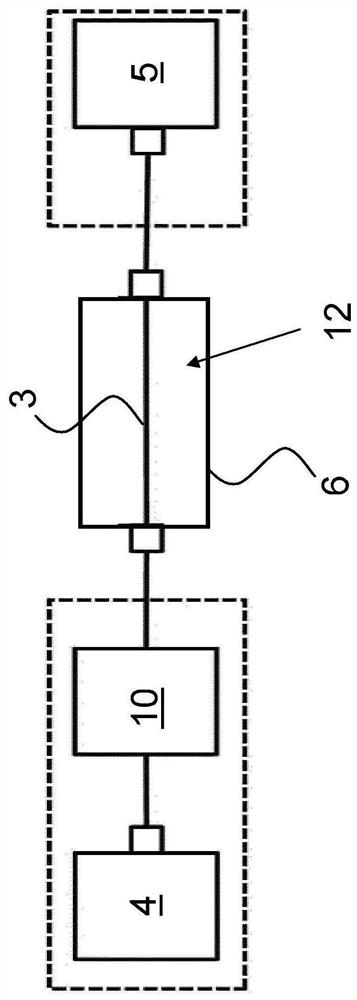

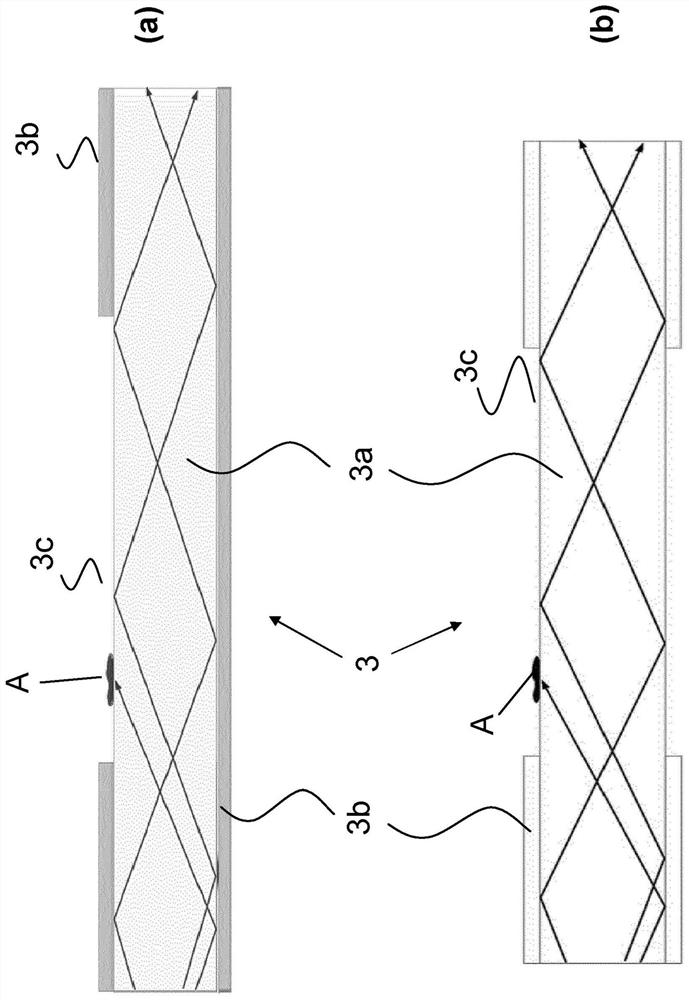

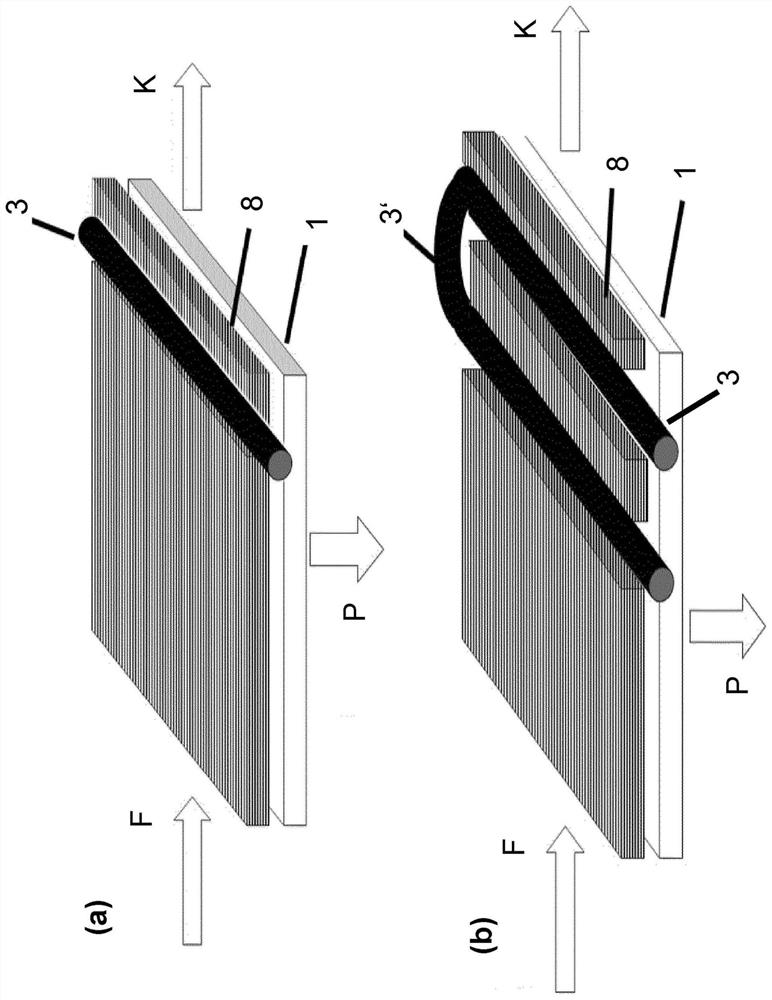

[0039] exist figure 1 A device for detecting deposits in a permeate producing membrane module is schematically shown in . The membrane module is designed here as a measuring module 12 and comprises at least one permeable or semipermeable membrane layer (in figure 1 Not shown in ), and at least one polymer optical fiber 3, which is incorporated into the membrane assembly (measurement assembly 12) as follows, so that the polymer optical fiber 3 is in contact with at least one membrane layer. At least one membrane layer of measuring assembly 12 is arranged here in liquid-tight housing 6 . The housing 6 can in particular be a pressure tube which, depending on the design of the membrane module, is able to withstand the high pressures used in conventional membrane separation processes such as microfiltration, ultrafiltration, nanofiltration or reverse osmosis.

[0040] One end of the polymer optical fiber 3 incorporated into the measurement assembly 12 is coupled to the transmitte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com