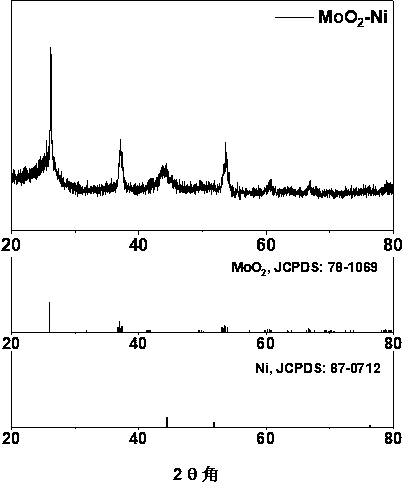

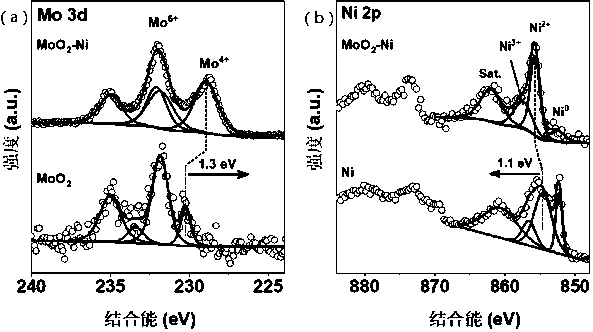

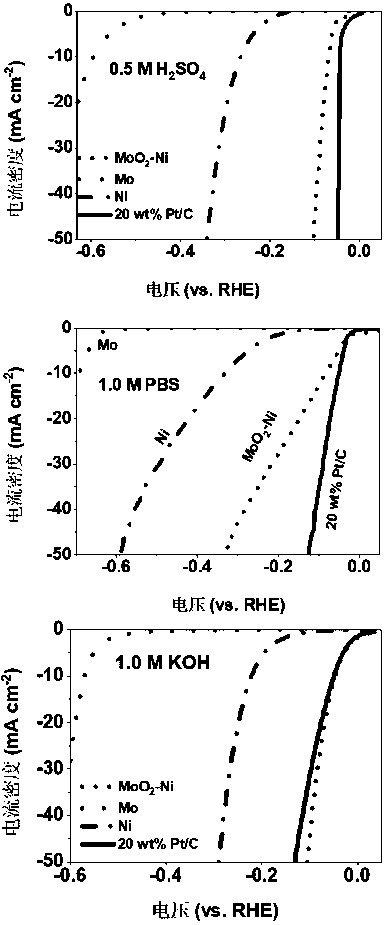

MoO2-Ni/CC composite material of hydrogen evolution electrocatalyst, and preparation method

A composite material and electrocatalyst technology applied in the field of hydrogen energy to achieve excellent electrocatalytic hydrogen evolution performance, simple preparation method and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Follow the steps below to prepare MoO 2 -Ni / CC composite material:

[0027] (1) Treatment of carbon cloth: Cut the carbon cloth into a size of 1x1.5 cm, then ultrasonically wash it in 0.5 mol / L sulfuric acid solution, deionized water and ethanol for 5 minutes, cycle wash three times, and dry it naturally for later use.

[0028] (2) Preparation of nickel nitrate solution: Weigh 1.16 g of nickel nitrate hexahydrate and dissolve it in 40 mL of deionized water, sonicate for 10 minutes, and prepare a 0.1 mol / L nickel nitrate solution for later use.

[0029] (3) Electrodeposition of nickel: The electrodeposition equipment is the French Bio-Logic VMP3 multi-channel electrochemical workstation, with carbon cloth as the working electrode, platinum sheet as the counter electrode, and a saturated calomel electrode as the reference electrode. Among them, using the configured nickel nitrate solution as the electroplating solution, at -10 mA / cm 2 Electrodeposition was carried out f...

Embodiment 2

[0041] Follow the steps below to prepare MoO 2 -Ni / CC composite material:

[0042] (1) Treatment of carbon cloth: Cut the carbon cloth into a size of 1x1.5 cm, then ultrasonically wash it in 0.5 mol / L sulfuric acid solution, deionized water and ethanol for 5 minutes, cycle wash three times, and dry it naturally for later use.

[0043] (2) Preparation of nickel nitrate solution: Weigh 1.16 g of nickel nitrate hexahydrate and dissolve it in 40 mL of deionized water, sonicate for 10 minutes, and prepare a 0.1 mol / L nickel nitrate solution for later use.

[0044] (3) Electrodeposition of nickel: The electrodeposition equipment is the French Bio-Logic VMP3 multi-channel electrochemical workstation, with carbon cloth as the working electrode, platinum sheet as the counter electrode, and a saturated calomel electrode as the reference electrode. Among them, using the configured nickel nitrate solution as the electroplating solution, at -10 mA / cm 2 Electrodeposition was carried out f...

Embodiment 3

[0052] Follow the steps below to prepare MoO 2 -Ni / CC composite material,

[0053] (1) Treatment of carbon cloth: Cut the carbon cloth into a size of 1x1.5 cm, then ultrasonically wash it in 0.5 mol / L sulfuric acid solution, deionized water and ethanol for 5 minutes, cycle wash three times, and dry it naturally for later use.

[0054] (2) Preparation of nickel nitrate solution: Weigh 1.16 g of nickel nitrate hexahydrate and dissolve it in 40 mL of deionized water, sonicate for 10 minutes, and prepare a 0.1 mol / L nickel nitrate solution for later use.

[0055] (3) Electrodeposition of nickel: The electrodeposition equipment is the French Bio-Logic VMP3 multi-channel electrochemical workstation, with carbon cloth as the working electrode, platinum sheet as the counter electrode, and a saturated calomel electrode as the reference electrode. Among them, using the configured nickel nitrate solution as the electroplating solution, at -10 mA / cm 2 Electrodeposition was carried out f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com