MoS2/NiCo2S4/CFP three-dimensional graded structure and preparation method thereof

A hierarchical structure, three-dimensional technology, applied in the field of electrocatalytic hydrogen evolution, can solve the problems of easy stacking of sheets and low conductivity limitations, and achieve the effects of large conductivity, increased conductivity, high electrocatalytic hydrogen evolution performance and cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The present invention utilizes two-step hydrothermal method to prepare MoS 2 / NiCo 2 S 4 / CFP three-dimensional hierarchical structure; by adjusting the reaction time and reaction temperature, adjust NiCo 2 S 4 Nanowire arrays and MoS 2 Geometric features of nanosheets. MoS in the present invention 2 / NiCo 2 S 4 A method for preparing a three-dimensional hierarchical structure of CFP, comprising the following steps:

[0028] (1) Nickel nitrate, cobalt nitrate and urea are selected and mixed thoroughly to obtain a uniformly dispersed mixed solution.

[0029] According to the mass fraction, add 0.5-1.5 parts of nickel nitrate, 1-3 parts of cobalt nitrate and 0.5-1.5 parts of urea, add the above reactants into 60mL of deionized water, and obtain a uniformly dispersed solution after stirring and ultrasonic treatment. .

[0030] (2) Using the mixed solution as the reactant, the loaded NiCo 2 o 4 Carbon fiber paper precursors for nanowire arrays.

[0031] Pour th...

Embodiment 1

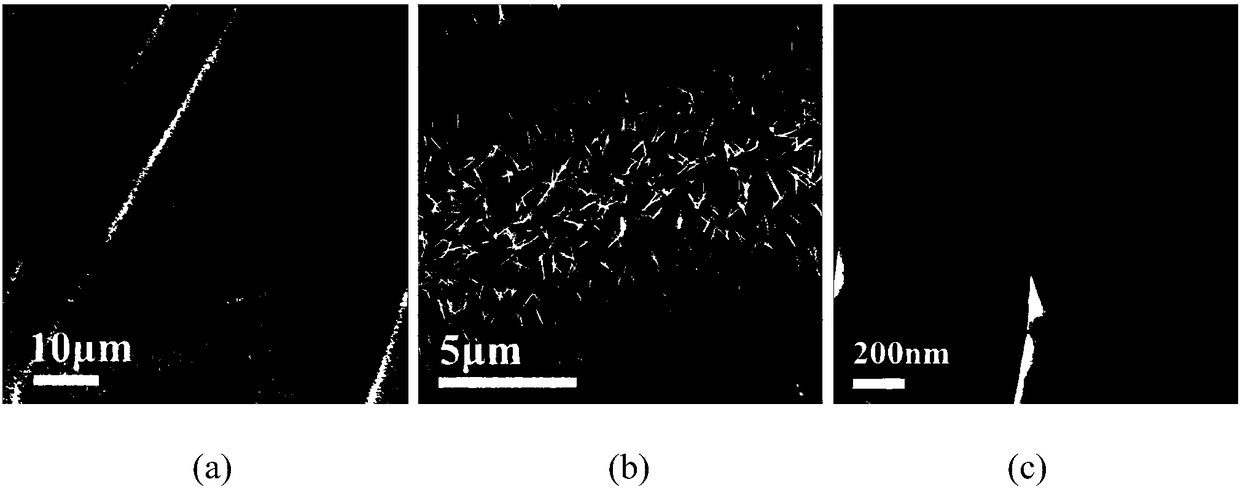

[0041] Using nickel nitrate, cobalt nitrate and urea mixture as reactants, according to the mass fraction, add 0.5 part of nickel nitrate, 1 part of cobalt nitrate and 0.5 part of urea to 60 mL of deionized water, hydrothermal reaction synthesis load Basic NiCo 2 o 4 The carbon fiber paper precursor of the nanowire array, the hydrothermal reaction temperature is 120°C, and the reaction time is 5h. Next, ammonium heptamolybdate tetrahydrate and sulfur powder solution were used as reactants, the molar ratio of which was 1:5, and the above-mentioned loaded base NiCo 2 o 4 Carbon fiber paper with nanowire arrays as precursor, hydrothermal reaction to synthesize MoS 2 / NiCo 2 S 4 / CFP three-dimensional hierarchical structure. The hydrothermal reaction temperature is 180°C, and the reaction time is 6h.

[0042] Basic NiCo supported on carbon fiber paper in this example 2 o 4 The density of nanowire arrays is small, NiCo 2 o 4 The nanowire array is tightly combined with th...

Embodiment 2

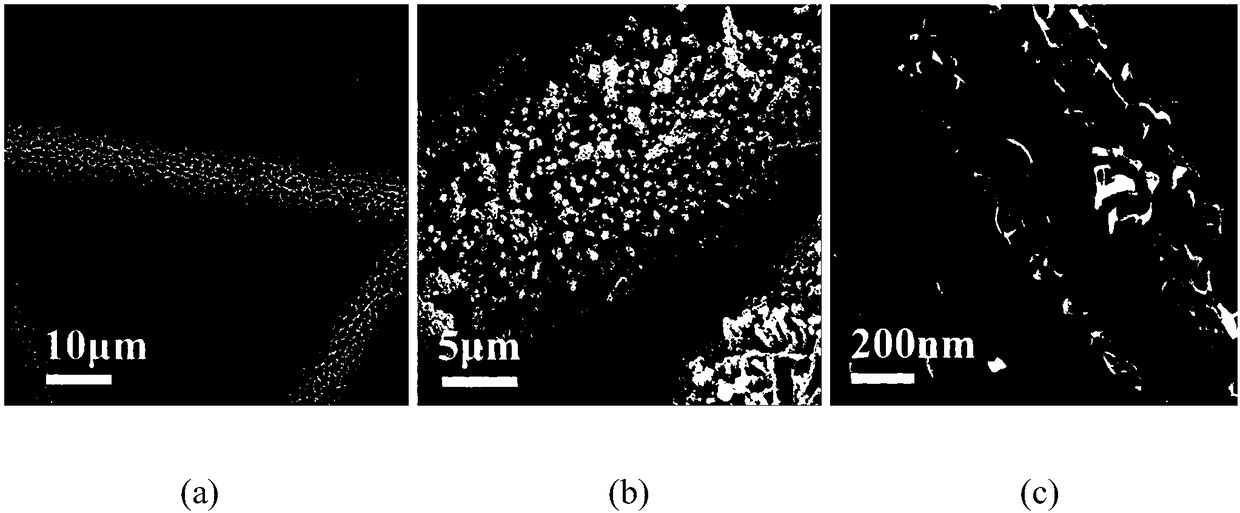

[0044] Using nickel nitrate, cobalt nitrate and urea mixture as reactants, according to the mass fraction, add 0.5 part of nickel nitrate, 1 part of cobalt nitrate and 0.5 part of urea to 60 mL of deionized water, hydrothermal reaction synthesis load Basic NiCo 2 o 4 The carbon fiber paper precursor of the nanowire array, the hydrothermal reaction temperature is 120°C, and the reaction time is 10h. Next, ammonium heptamolybdate tetrahydrate and sulfur powder solution were used as reactants, the molar ratio of which was 1:5, and the above-mentioned loaded base NiCo 2 o 4 Carbon fiber paper with nanowire arrays as precursor, hydrothermal reaction to synthesize MoS 2 / NiCo 2 S 4 / CFP three-dimensional hierarchical structure. The hydrothermal reaction temperature is 180°C, and the reaction time is 6h.

[0045] Basic NiCo supported on carbon fiber paper in this example 2 o 4 Nanowire arrays are less dense, NiCo 2 o 4 The nanowire array is tightly combined with the carbon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com