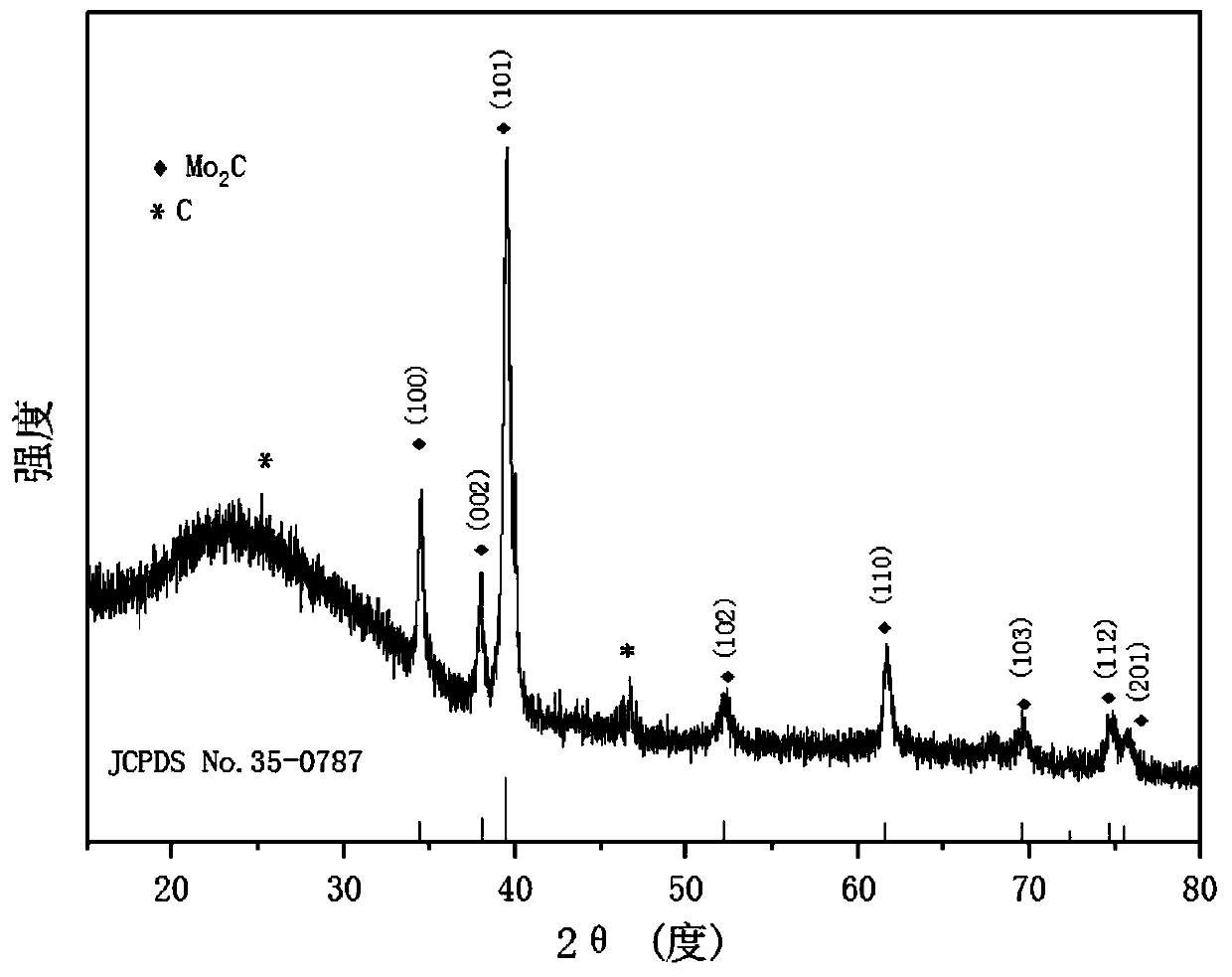

M2C/carbon nanosheet composite material and preparation method and application thereof

A technology of composite materials and carbon nanosheets, applied in the field of electrocatalytic materials, can solve the problems of reducing catalytic active area, small specific surface area, particle aggregation, etc., and achieve high electrocatalytic hydrogen evolution capacity, large specific surface area and electrochemical active area, The effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] (1) 0.5g molybdenum disulfide, base, 0.2g of dopamine hydrochloride was placed in 100mL of deionized water (pH of the mixture was 8.5) for the first contact at 25°C for 24 hours, and the product was washed and dried to obtain the molybdenum disulfide / polydopamine complex.

[0081] (2) Carbonizing the obtained molybdenum disulfide / polydopamine compound in a muffle furnace at a temperature of 600° C. in a nitrogen atmosphere for 2 hours to obtain a molybdenum disulfide / carbon compound;

[0082](3) Immerse the molybdenum disulfide / carbon composite in a 7mol / L potassium hydroxide solution for the second contact at 25°C. The mass ratio of the molybdenum disulfide / carbon composite to potassium hydroxide is 1:3, and then The first drying is carried out at 180°C, and the dried potassium hydroxide / molybdenum disulfide / carbon mixture is heat-treated in a muffle furnace at a temperature of 800°C in a nitrogen atmosphere for 1 hour, and the product is washed with deionized water a...

Embodiment 2

[0084] (1) 0.25g molybdenum disulfide, Base, 0.2g of dopamine hydrochloride was placed in 100mL of deionized water (pH of the mixture was 8) for the first contact at 20°C for 18 hours, and the product was washed and dried to obtain the molybdenum disulfide / polydopamine complex;

[0085] (2) Carbonizing the obtained molybdenum disulfide / polydopamine compound in a muffle furnace at a temperature of 700° C. in a nitrogen atmosphere for 1 hour to obtain a molybdenum disulfide / carbon compound;

[0086] (3) Immerse the molybdenum disulfide / carbon composite in a 5mol / L potassium hydroxide solution at 20°C for the second contact, wherein the mass ratio of the molybdenum disulfide / carbon composite to potassium hydroxide is 1:2, and then Carry out the first drying at 150°C, heat-treat the dried potassium hydroxide / molybdenum disulfide / carbon mixture in a muffle furnace at a temperature of 750°C in a nitrogen atmosphere for 1.5 hours, wash the product with water and dilute hydrochloric ...

Embodiment 3

[0088] (1) 1g molybdenum disulfide, Base, 0.36g of dopamine hydrochloride was placed in 100mL of deionized water (pH of the mixture was 9) and stirred at 30°C for 12 hours, and the product was washed and dried to obtain the molybdenum disulfide / polydopamine complex;

[0089] (2) Carbonizing the obtained molybdenum disulfide / polydopamine compound in a muffle furnace at a temperature of 650° C. in a nitrogen atmosphere for 3 hours to obtain a molybdenum disulfide / carbon compound;

[0090] (3) Immerse the molybdenum disulfide / carbon composite in a 10mol / L potassium hydroxide solution at 30°C for the second contact, wherein the mass ratio of the molybdenum disulfide / carbon composite to potassium hydroxide is 1:4, After that, the first drying is carried out at 150°C, and the dried potassium hydroxide / molybdenum disulfide / carbon mixture is heat-treated in a muffle furnace at a temperature of 900°C in a nitrogen atmosphere for 0.5 hours, and the product is washed with water and dilu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com