Autocatalytic flotation reagent for sulfur-containing refractory minerals, and preparation method and application thereof

A catalyst and reagent technology, applied in the field of autocatalytic flotation reagents, can solve the problems of increasing the water content of red mud, high particle size requirements, weakening the sedimentation capacity of red mud, etc., to improve the rate of sulfur reduction and quality improvement, high comprehensive separation efficiency, EFFECTS FOR DIRECT APPLICATION

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The application of an autocatalytic flotation agent for sulfur-containing refractory minerals in the removal of sulfur from sulfur-containing refractory minerals, the mineral type is bauxite, and the sulfur content is 4.7wt%.

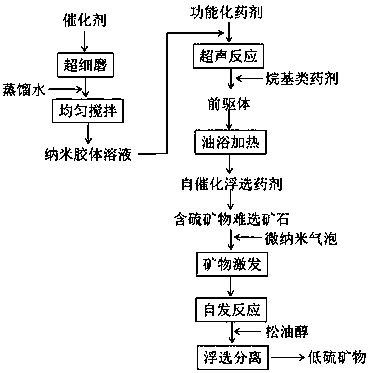

[0025] Such as figure 1 As shown, the specific steps are as follows: firstly, prepare the functionalized agent consisting of 65 parts of 5-amino-2-mercaptobenzothiazole, 35 parts of 1-propylsulfonic acid-3-methylimidazole and 5 g / L , a nano-colloid solution with a particle size of 80 nm (the mass part composition of the catalyst is Ni / γ-Al 2 o 3 50 parts, CuSO 4 30 parts, ZnSO 4 20 parts), the functionalized agent and the nanocolloid solution were mixed, and reacted for 15 min under the condition of an ultrasonic force field of 50 W to form a precursor; the mass parts were composed of 45 parts of didecyl dimethyl ammonium chloride, Add 40 parts of tetrabutylammonium bisulfate and 15 parts of tetradecyltrimethylammonium chloride to the precurs...

Embodiment 2

[0027] An application of an autocatalytic flotation agent for sulfur-containing refractory minerals in the removal of sulfur from sulfur-containing refractory minerals. The mineral type is gold ore, and the sulfur content is 3.2wt%.

[0028] Such as figure 1 As shown, the specific steps are as follows: firstly prepare the functionalized agent with the mass parts consisting of 68 parts of 5-amino-2-mercaptobenzothiazole and 32 parts of 1-propylsulfonic acid-3-methylimidazole and the concentration is 8 g / L, particle size is 60 nm catalyst nano colloid solution (catalyst mass part composition is Ni / γ-Al 2 o 3 35 parts, CuSO 4 40 parts, ZnSO 425 parts); the functionalized agent and the nanocolloid solution were mixed, and reacted for 18 min under the condition of an ultrasonic force field of 60 W to form a precursor; the mass parts were composed of 50 parts of didecyl dimethyl ammonium chloride, 35 parts of tetrabutylammonium bisulfate and 15 parts of tetradecyltrimethylammon...

Embodiment 3

[0030] The application of an autocatalytic flotation agent for sulfur-containing refractory minerals in the desulfurization of sulfur-containing refractory minerals, the mineral type is high-sulfur ore, and the sulfur content is 7.5wt%.

[0031] Such as figure 1 As shown, the specific steps are as follows: firstly prepare the functionalized agent consisting of 70 parts of 5-amino-2-mercaptobenzothiazole and 30 parts of 1-propylsulfonic acid-3-methylimidazole by mass and the concentration is 7 g / L, particle size is 75 nm catalyst nano colloid solution (catalyst mass part composition is Ni / γ-Al 2 o 3 40 parts, CuSO 4 40 parts, ZnSO 4 20 parts); the functional agent and the nanocolloid solution were mixed, and reacted for 20 min under the condition of an ultrasonic force field of 80 W to form a precursor; the mass parts were composed of 48 parts of didecyl dimethyl ammonium chloride, 30 parts of tetrabutylammonium bisulfate and 22 parts of tetradecyltrimethylammonium chlorid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com