High-weather-resistant low-temperature thermosetting epoxy module adhesive and preparation method thereof

A low-temperature heat, epoxy mold technology, used in epoxy resin adhesives, adhesives, non-polymer adhesive additives, etc., can solve problems such as large shrinkage, compatibility problems, and curing agents that cannot be cured. Achieve the effects of excellent water resistance, excellent bond strength and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

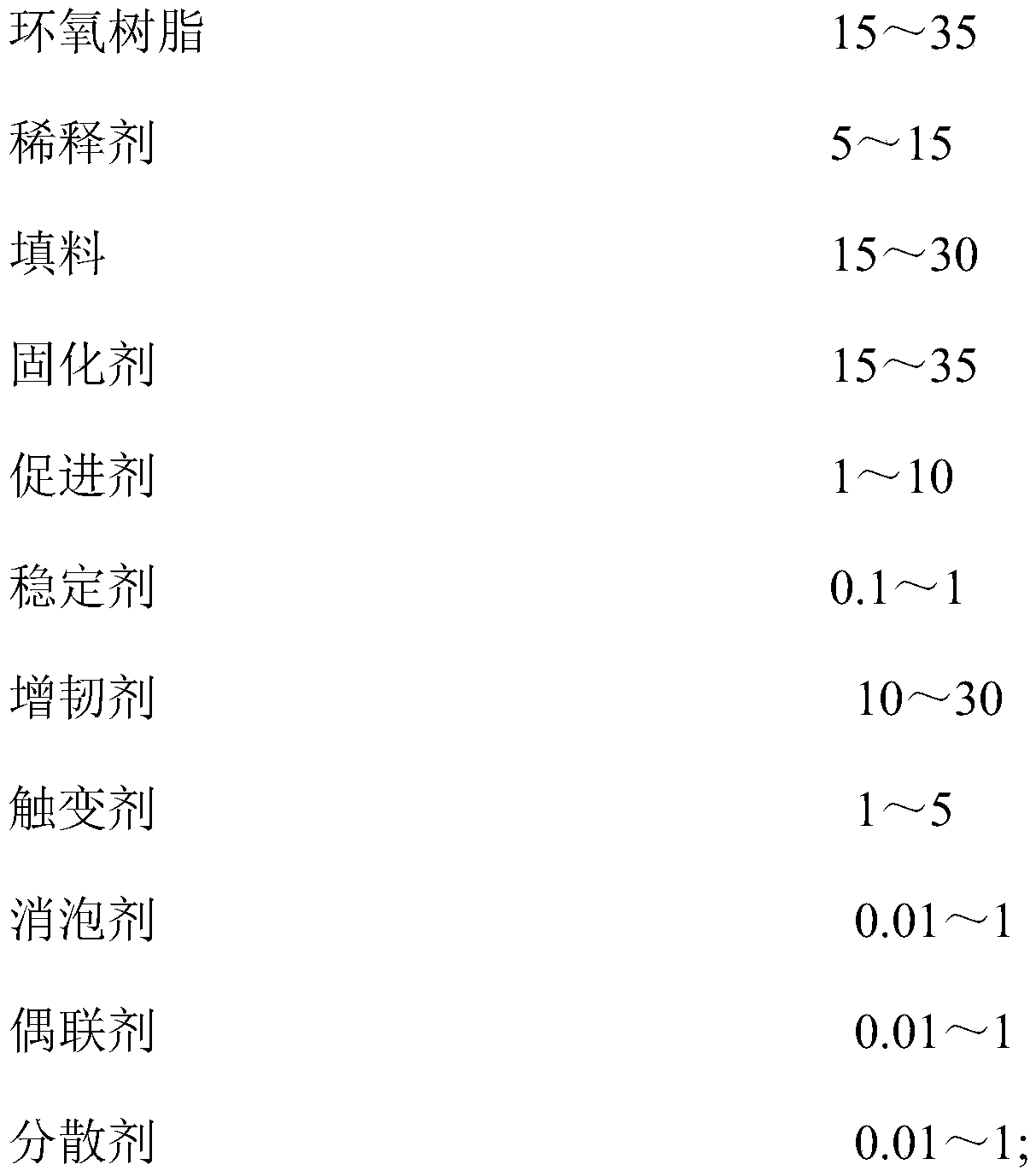

[0042] A low-temperature thermosetting epoxy module glue with high weather resistance, its raw materials and composition are as follows (parts by weight):

[0043]

[0044]

[0045] Among them, YX-8000 is a hydrogenated bisphenol A epoxy resin purchased from Mitsubishi Chemical Co., Ltd., CE01MO is a cyanate-modified epoxy resin purchased from Yangzhou Tianqi New Materials Co., Ltd., and BPA328 is purchased from Nippon Shokubai. Co., Ltd.'s acrylate rubber particles are dispersed in a mixture of two-part A epoxy resin; amorphous silica R805 is a thixotropic agent purchased from Evonik Industrial Group; BYK-A530 is a methyl alkylpolyester purchased from BYK, Germany Silicone defoamer; Plenact AL-M is a coupling agent of diisopropylethoxy aluminum purchased from Ajinomoto Co., Ltd. of Japan.

[0046] The preparation method of accelerator C-1, comprises the following steps:

[0047] Add 16.5g of 3,3',4,4'-benzophenonetetraacid dianhydride and 150g of xylene under nitrogen ...

Embodiment 2

[0056] A low-temperature thermosetting epoxy module glue with high weather resistance, its raw materials and composition are as follows (parts by weight):

[0057]

[0058] Among them, CEL2021P is an aliphatic epoxy resin purchased from DAICEL Chemical Co., Ltd., CE01MO is a cyanate ester modified epoxy resin purchased from Yangzhou Tianqi New Materials Co., Ltd. The mixture of rubber particles dispersed in cycloaliphatic epoxy resin; amorphous silica R805 is a thixotropic agent purchased from Evonik Industrial Group; BYK-A530 is a methyl alkylpolysiloxane purchased from BYK, Germany Defoamer; Plenact AL-M is a coupling agent of diisopropylethoxy aluminum purchased from Ajinomoto Co., Ltd. of Japan.

[0059] The preparation method of accelerator C-1, comprises the following steps:

[0060] Add 16.5g of 3,3',4,4'-benzophenonetetraacid dianhydride and 150g of xylene under nitrogen atmosphere, and raise the temperature to 55°C, add 8.5g of 2-methylimidazole, stir at 55°C for ...

Embodiment 3

[0069] A low-temperature thermosetting epoxy module glue with high weather resistance, its raw materials and composition are as follows (parts by weight):

[0070]

[0071] Among them, YX-8000 is a hydrogenated bisphenol A epoxy resin purchased from Mitsubishi Chemical Co., Ltd., CE01MO is a cyanate-modified epoxy resin purchased from Yangzhou Tianqi New Materials Co., Ltd., and BPA328 is purchased from Nippon Shokubai. Co., Ltd.'s acrylate rubber particles are dispersed in a mixture of two-part A epoxy resin; amorphous silica H18 is a thixotropic agent purchased from Wacker Industry Group in Germany; BYK-A530 is a methyl alkyl group purchased from BYK in Germany Polysiloxane defoamer; PlenactAL-M is a coupling agent of diisopropylethoxyaluminum purchased from Ajinomoto Co., Ltd. of Japan.

[0072] The preparation method of accelerator C-1, comprises the following steps:

[0073] Add 16.5g of 3,3',4,4'-benzophenonetetraacid dianhydride and 150g of xylene under nitrogen atm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com