Testing device and testing method for optical uniformity of biaxial crystal in principal axis direction

A technology of optical uniformity and biaxial crystal, applied in the direction of using optical device, measuring device, phase influence characteristic measurement, etc., can solve the problems of increased detection cost, cumbersome test steps, harsh detection conditions, etc. Suitable for promotion and use, with little effect on the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

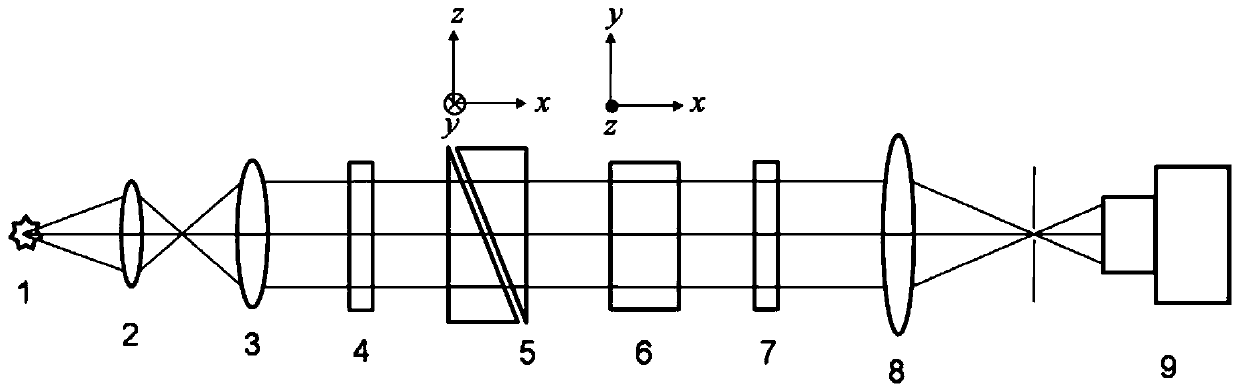

[0029] Example 1: The device for testing the optical uniformity of the biaxial crystal in the principal axis direction of the present invention

[0030] Such as figure 1 As shown, the device for testing the optical uniformity of the biaxial crystal in the main axis direction of the present invention includes a light source 1, a condenser lens 2, a collimator lens 3, a polarizer 4, a phase compensator 5, and a detector arranged in sequence along the optical axis. The polarizer 7, the imaging lens 8 and the camera 9, and the crystal to be measured 6 is placed between the phase compensator 5 and the analyzer 7. The phase compensator 5 is composed of two optical wedges. The relative position is used to adjust the phase retardation, wherein the material of the optical wedge is a crystal with the same composition as the crystal to be tested and with good optical uniformity.

[0031] In this embodiment, the light source 1 is a white point light source, more specifically an LED lamp or a ...

Embodiment 2

[0040] Example 2: Adopt figure 1 Method for testing the optical uniformity of crystals in the described embodiment

[0041] 1) Adjust the relative positions of the light source 1, the condenser lens 2, and the collimator lens 3 so that the expanded probe light exits in parallel in the horizontal direction;

[0042] 2) Adjust the positions and angles of the polarizer 4, the analyzer 7, the imaging lens 8, and the camera 9 so that the incident parallel light is incident on the center of the above-mentioned optical element; set the reference polarization direction of the polarizer 4 to the horizontal or vertical direction, The polarization directions of the analyzer 4 and the polarizer 7 are perpendicular to each other, and the picture taken by the camera 9 should be a uniform black background;

[0043] 3) Insert the crystal 6 to be tested to ensure that the probe light can completely cover the light aperture of the crystal. The direction of light is the main axis direction of the crys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com