Wall-mounted plant packed bed

A packing bed and wall-mounted technology, which is applied in the field of environmental engineering, can solve the problems of difficult land occupation and utilization of urban rivers, and achieve the effects of simple and convenient installation, efficient removal, and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

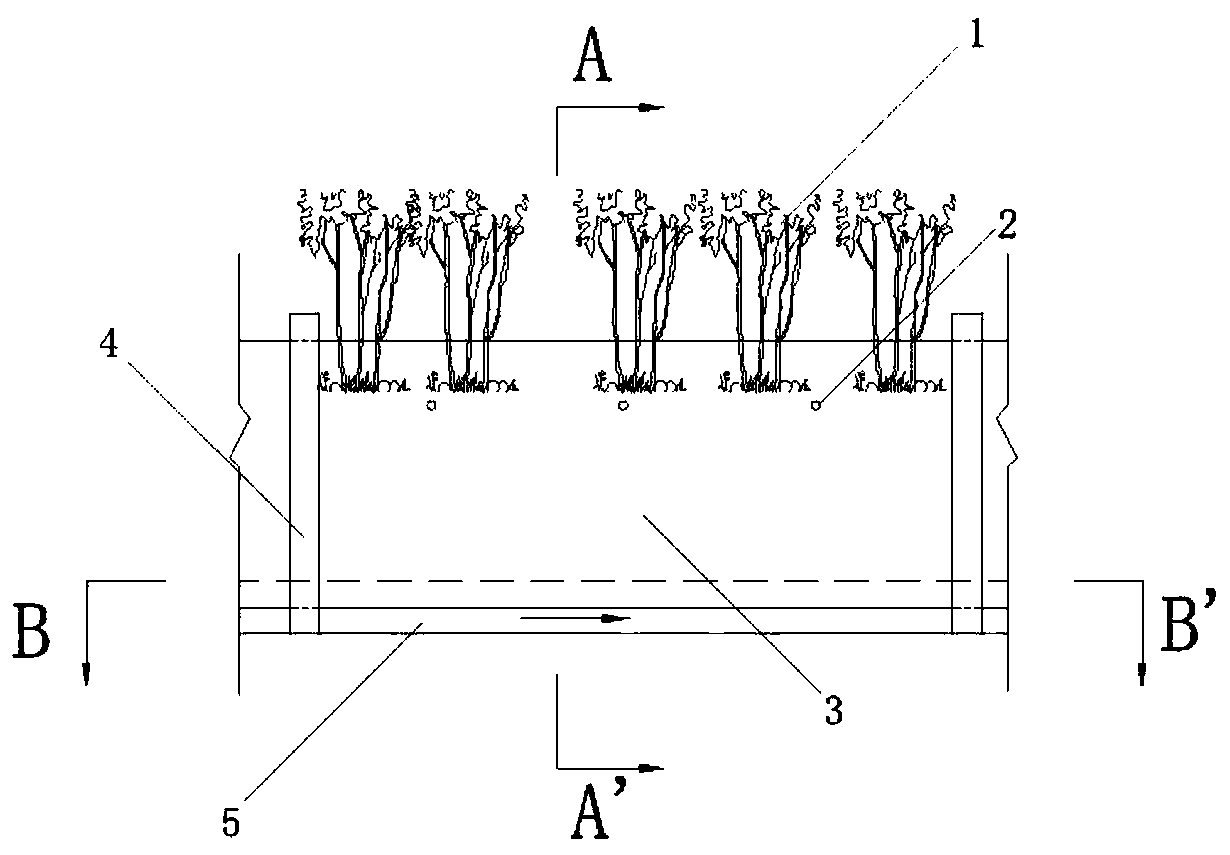

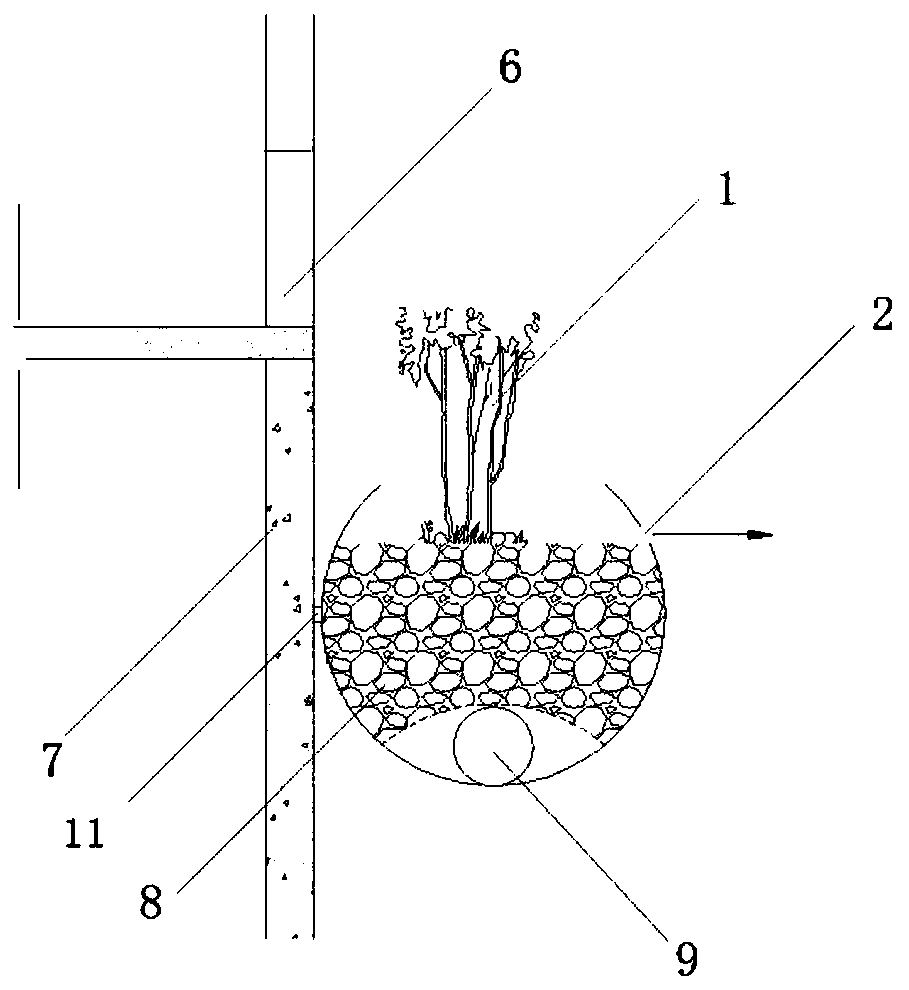

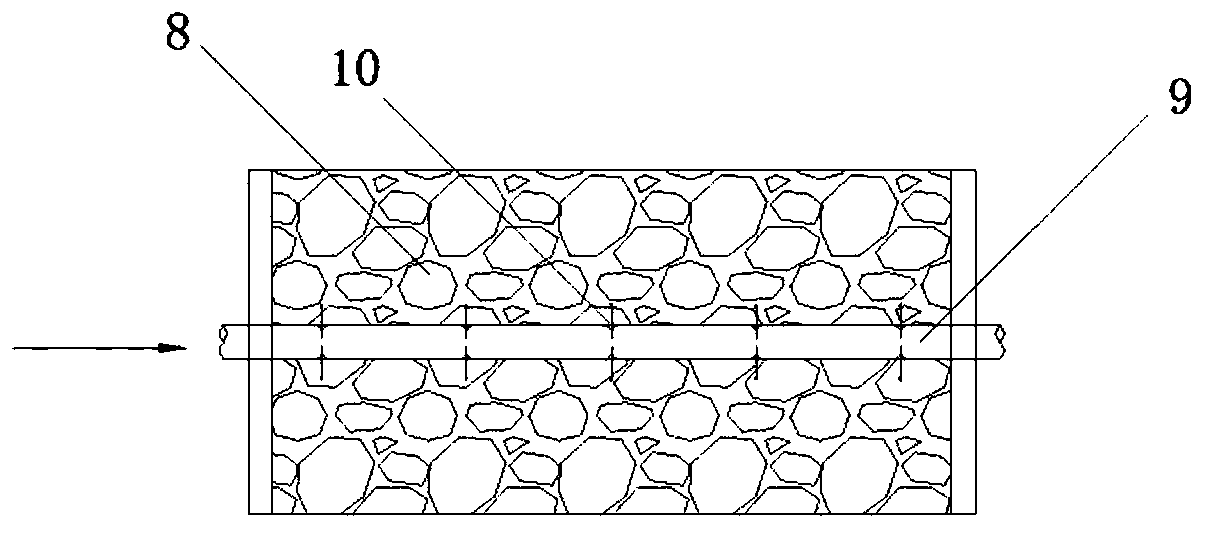

[0029] as attached Figure 1-4 A wall-mounted plant packing bed is shown, which is composed of plants, packing layers, water distribution boards and water inlet pipes. The packing bed is made of common UPVC pipes. The lower part is placed at the bottom of the packing bed; the packing layer is set on the packing bed, and the packing layer is laid with ceramsite and volcanic rock in sequence from bottom to top; the water distribution pipe is buried in the packing layer along the base and kept parallel to the embankment; the plant setting On the filler layer, the plants are aquatic plants; the height of the baffle is 1.1m; the thickness of the filler layer is 0.8m; there are several drainage holes on the top of the filler bed, and the height of the centerline of the drainage holes from the upper edge of the base is 0.98m , the distance between two adjacent drainage holes is 0.1m; there are water outlet holes on both sides of the water inlet pipe wall, and the distance between two...

Embodiment 2

[0042] The height of the baffle is 1.3m; the thickness of the packing layer is 1m; there are several drainage holes on the baffle, and the height of the center line of the drainage holes from the upper edge of the base is 1.02m.

[0043] Wherein, the diameter of the outlet hole is 5 cm.

[0044] Among them, the minimum distance between the baffle and the embankment is 10cm.

[0045] Among them, the aquatic plants are cattail grass, and the water load is 1-5gCOD / m 2 .d, the planting density of cattail grass is 4-6 plants / m 2 , The hydraulic retention time of the device is 1-2h, and the mud discharge cycle is 7-15 days. All the other are with embodiment 1.

[0046] The technical solution of this embodiment was applied to the water treatment of the Baoxiang River in Kunming City, and various indicators of the inflow and outflow water were analyzed and compared. The comparison results are shown in Table 1.

[0047] Table 1. Comparative results of Baoxiang River water treatment...

Embodiment 3

[0051] The height of the baffle is 1.2m; the thickness of the filler layer is 0.9m; there are several drainage holes on the baffle, and the height of the centerline of the drainage holes from the upper edge of the base is 1m.

[0052] Wherein, the diameter of the outlet hole is 4.5 cm.

[0053] Among them, the minimum distance between the baffle and the embankment is 7.5cm.

[0054] Among them, the aquatic plants are water onions, and the influent load is greater than 5gCOD / m 2 .d, the planting density of water onion is 10 plants / m 2 , The hydraulic retention time of the device is 2-3h. All the other are with embodiment 1.

[0055] It can be known by calculation that the amount of water that can be treated every month by the device of this embodiment is 529.8m 3 , the packing replacement cycle is 3 years, and the treatment cost is 0.06 yuan / m³.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com