System and method for recovering byproducts in epoxypropane production by HPPO process

A recovery system and technology of propylene oxide, applied in the field of separation, can solve problems such as waste of resources, achieve the effects of reducing COD, facilitating subsequent processing, and improving resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

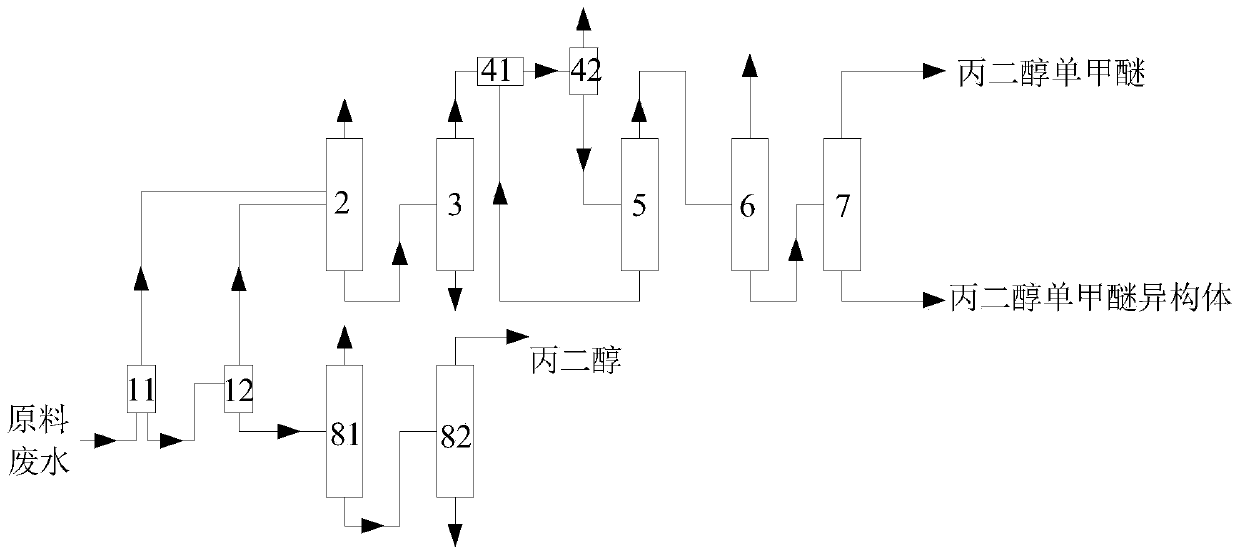

[0079] This embodiment provides a system for recovering by-products of propylene oxide produced by HPPO method. The system for recovering by-products of propylene oxide produced by HPPO method includes an evaporation unit, a propylene glycol recovery unit and a propylene glycol methyl ether recovery unit.

[0080] The evaporation unit includes a first evaporator 11 and a second evaporator 12 connected in sequence.

[0081] Described propylene glycol recovery unit comprises the first propylene glycol rectification tower 81 and the second propylene glycol rectification tower 82 connected successively, and the bottom outlet of the first propylene glycol rectification tower 81 is connected with the inlet of the second propylene glycol rectification tower 82 ; The feed port of the first propylene glycol rectifying tower 81 is connected with the drain port of the second evaporator 12 .

[0082] The propylene glycol methyl ether recovery unit includes a demethanol rectification tower...

Embodiment 2

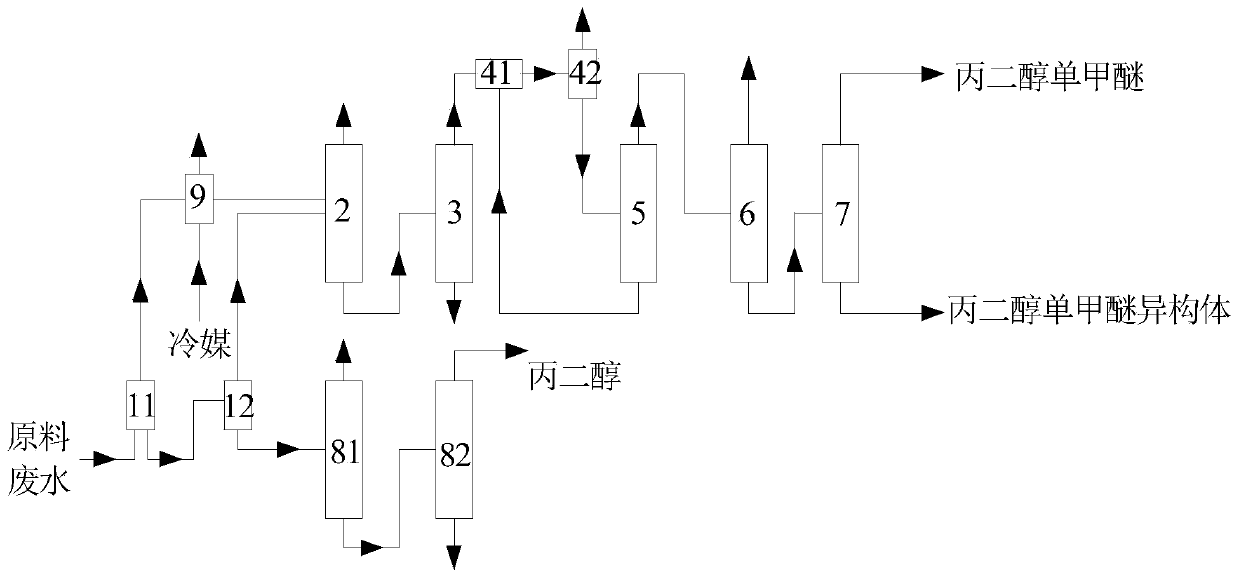

[0086] This embodiment provides a system for recovering by-products of propylene oxide produced by HPPO method. The system for recovering by-products of propylene oxide produced by HPPO method includes an evaporation unit, a propylene glycol recovery unit and a propylene glycol methyl ether recovery unit.

[0087] The evaporation unit includes a first evaporator 11 and a second evaporator 12 connected in sequence.

[0088] Described propylene glycol recovery unit comprises the first propylene glycol rectification tower 81 and the second propylene glycol rectification tower 82 connected successively, and the bottom outlet of the first propylene glycol rectification tower 81 is connected with the inlet of the second propylene glycol rectification tower 82 ; The feed port of the first propylene glycol rectifying tower 81 is connected with the drain port of the second evaporator 12 .

[0089] The propylene glycol methyl ether recovery unit includes a demethanol rectification tower...

Embodiment 3

[0093] This embodiment provides a system for recovering by-products of propylene oxide produced by HPPO method. The system for recovering by-products of propylene oxide produced by HPPO method includes an evaporation unit, a propylene glycol recovery unit and a propylene glycol methyl ether recovery unit.

[0094] The evaporation unit includes a first evaporator 11 and a second evaporator 12 connected in sequence.

[0095] Described propylene glycol recovery unit comprises the first propylene glycol rectification tower 81 and the second propylene glycol rectification tower 82 connected successively, and the bottom outlet of the first propylene glycol rectification tower 81 is connected with the inlet of the second propylene glycol rectification tower 82 ; The feed port of the first propylene glycol rectifying tower 81 is connected with the drain port of the second evaporator 12 .

[0096] The propylene glycol methyl ether recovery unit includes a demethanol rectification tower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com