Preparation method of starch and apigenin self-assembly body and purpose thereof in aspect of starch digestion inhibition

A technology of assembly and apigenin, which is applied in the field of food nutrition and processing, can solve the problems of chemical pollution of products, and achieve the effect of strong controllability, low cost and inhibition of digestion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

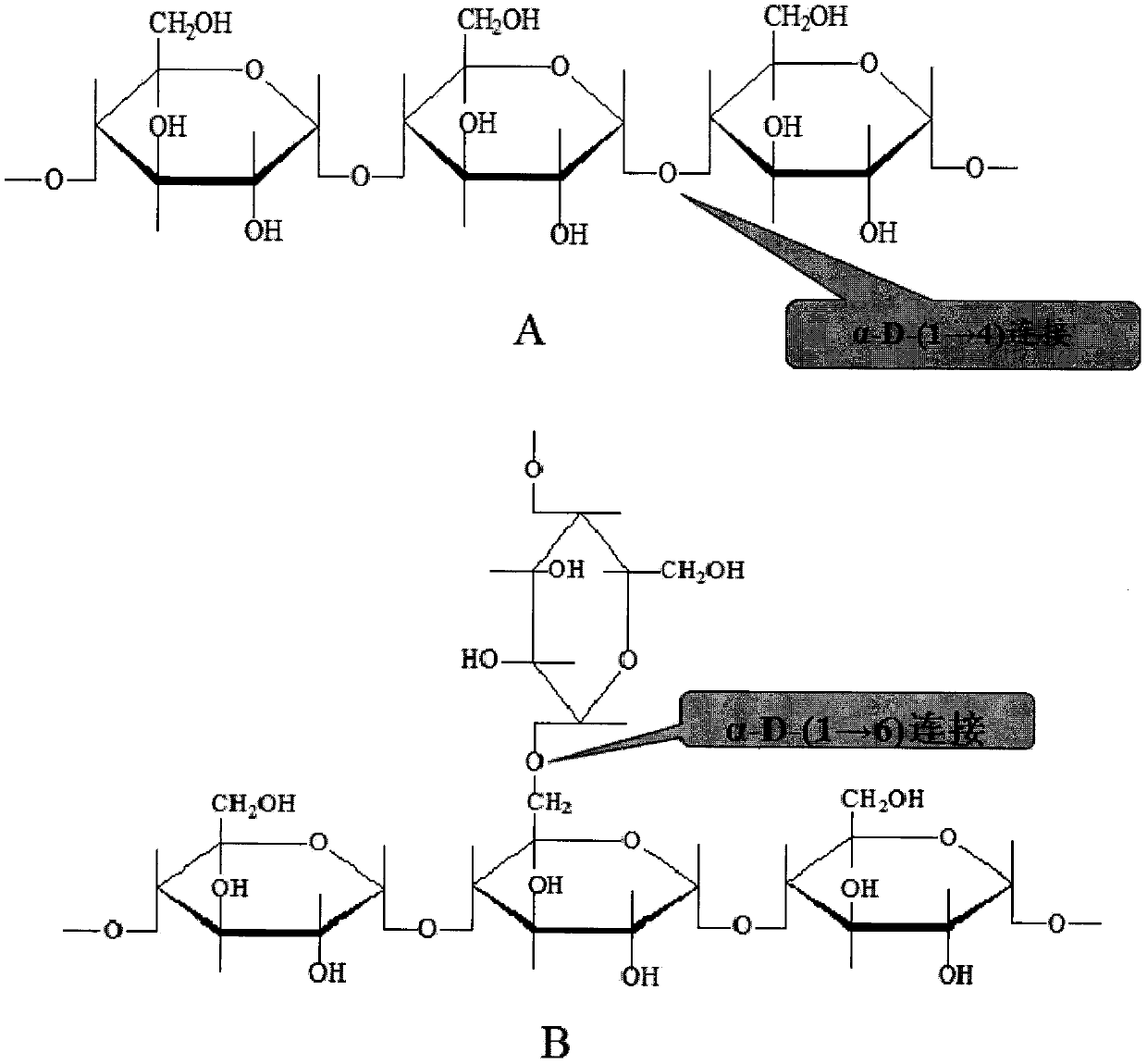

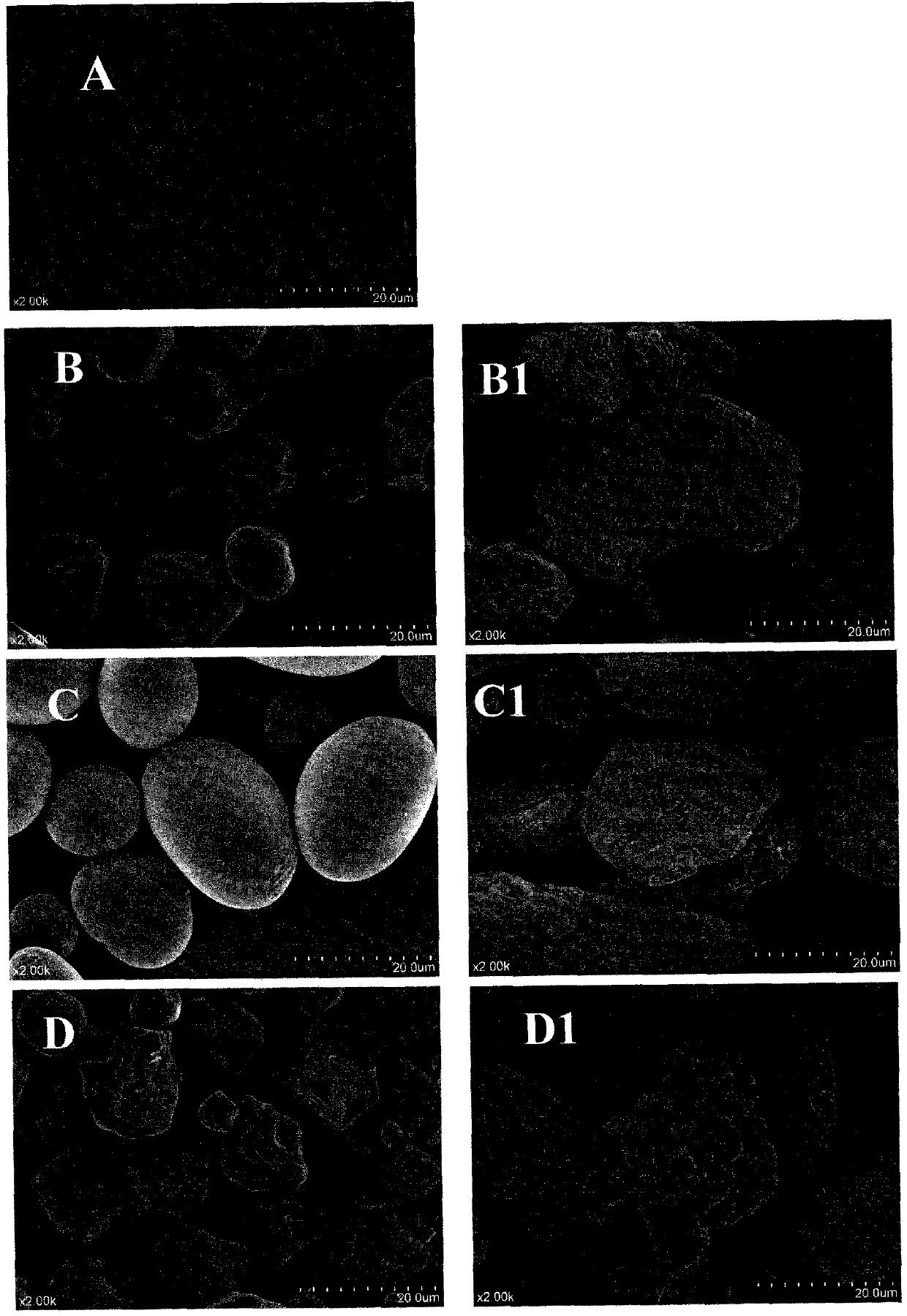

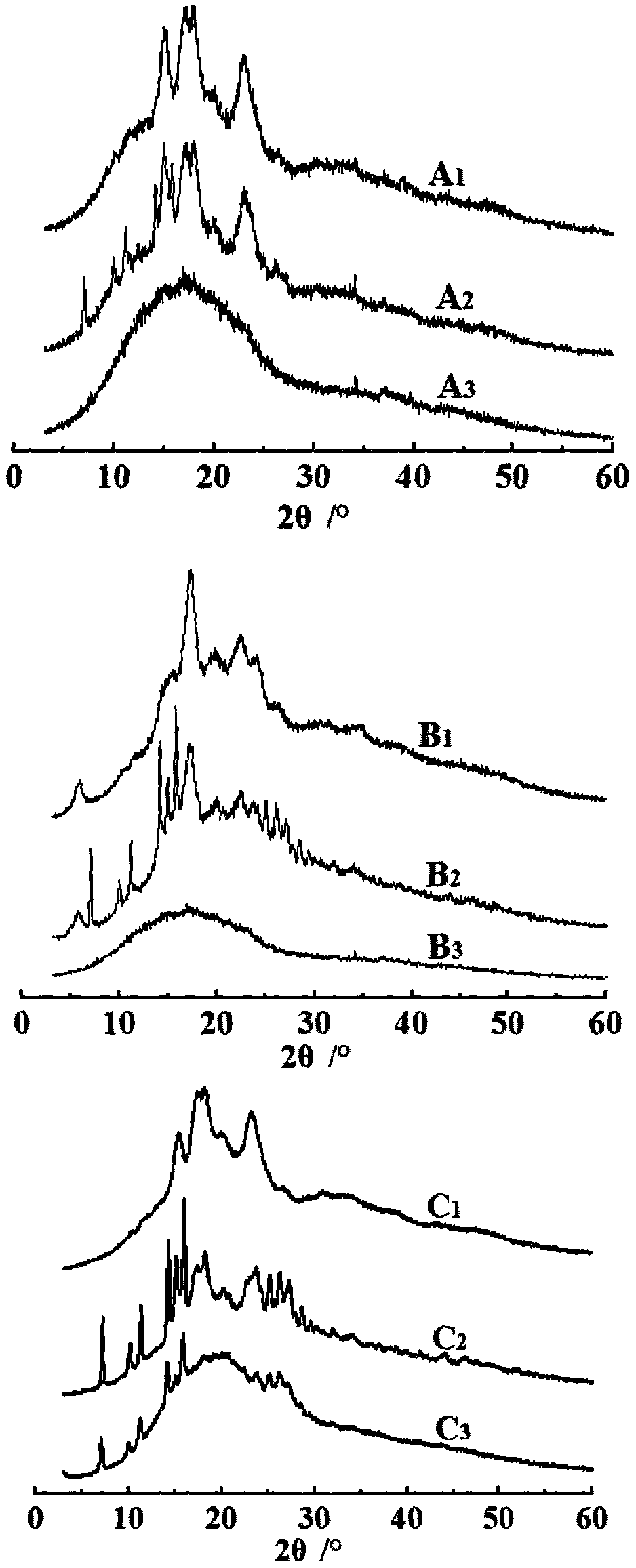

Method used

Image

Examples

Embodiment 1

[0032]Mix 20g of cornstarch and 2g of apigenin evenly, place them in the ball milling tank of the planetary ball mill, add zirconia balls according to the mass ratio of the balls to the mixture close to 2:1, and control the total volume of the balls and materials to be no less than 20% of the total volume of the ball milling tank. 1 / 3, no more than 2 / 3 of the total volume of the ball mill tank, run the ball mill at a speed of 700r / min; after the ball mill has been running for 30 hours, pick out the zirconia balls, and take the product obtained from the ball mill out of the ball mill tank; use 66mL Absolute ethanol is used to wash the apigenin attached to the surface of the ball-milled product; the washed product is suction-filtered, dried, and passed through a 100-mesh sieve to obtain a cornstarch-apigenin self-assembly. The embedding rate of apigenin in the corn starch-apigenin self-assembly is 29.91%; the content of apigenin is 30.05 mg / g. The digestibility of the self-assem...

Embodiment 2

[0034] Mix 20g of cornstarch and 3g of apigenin evenly, place them in the ball milling tank of the planetary ball mill, add zirconia balls according to the mass ratio of the balls to the mixture close to 2:1, and control the total volume of the balls and the material to not less than 1 / 2 of the total volume of the ball milling tank. 1 / 3, no more than 2 / 3 of the total volume of the ball mill tank, run the ball mill at a speed of 700r / min; after the ball mill has been running for 35 hours, pick out the zirconia balls, and take the product obtained from the ball mill out of the ball mill tank; use 69mL Absolute ethanol is used to wash the apigenin attached to the surface of the ball-milled product; the washed product is suction-filtered, dried, and passed through a 100-mesh sieve to obtain a cornstarch-apigenin self-assembly. The embedding rate of apigenin in the cornstarch-apigenin self-assembly is 32.17%; the content of apigenin is 48.30 mg / g. The digestibility of the self-asse...

Embodiment 3

[0036] Mix 20g of cornstarch and 4g of apigenin evenly, place them in the ball milling tank of the planetary ball mill, add zirconia balls according to the mass ratio of the balls to the mixture close to 2:1, and control the total volume of the balls and materials to be no less than 20% of the total volume of the ball milling tank. 1 / 3, no more than 2 / 3 of the total volume of the ball mill tank, run the ball mill at a speed of 700r / min; after the ball mill has been running for 40 hours, pick out the zirconia balls, and take the product obtained from the ball mill out of the ball mill tank; use 72mL Absolute ethanol is used to wash the apigenin attached to the surface of the ball-milled product; the washed product is suction-filtered, dried, and passed through a 100-mesh sieve to obtain a cornstarch-apigenin self-assembly. The embedding rate of apigenin in the corn starch-apigenin self-assembly was 35.71%; the content of apigenin was 71.51 mg / g. The digestibility of the self-as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com