An environmentally friendly building insulation material

A technology for building heat preservation and environmental protection, which is applied to ceramic products, other household appliances, household appliances, etc., can solve the problems that are not particularly ideal, and achieve the effects of increasing the equilibrium adsorption capacity, reducing indoor pollution, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] An environmentally friendly building insulation material, comprising the following raw materials in parts by weight: 60 parts of recycled construction waste materials, 10 parts of ordinary Portland cement, 3 parts of quicklime, 10 parts of modified diatomite, and 4 parts of lignocellulose;

[0040] Wherein, the preparation process of modified diatomite comprises the following steps:

[0041] (1) Grinding the shells to obtain shell powder with a particle size of 80-120 nm;

[0042] (2) washing the shell powder prepared in step (1) with a sodium hydrogen phosphate solution to obtain liquid shell powder;

[0043] (3) The liquid-laden shell powder obtained in step (2) is incubated at 500° C. for 10 minutes, rinsed with tap water, and dried to obtain active shell powder;

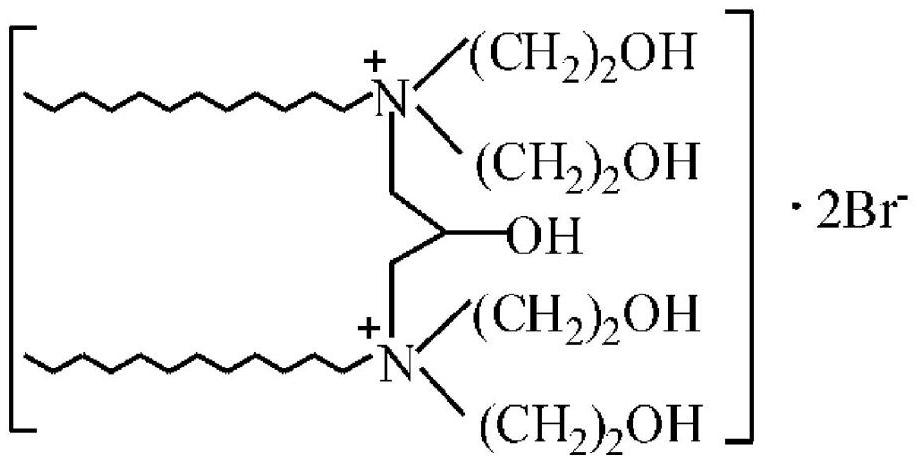

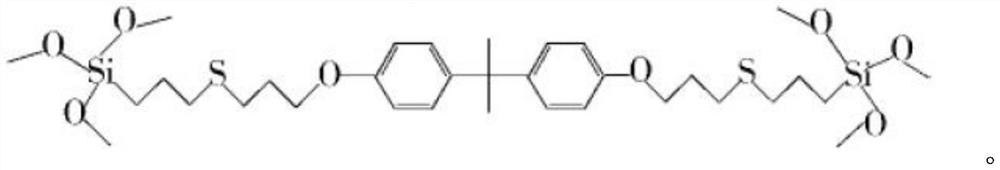

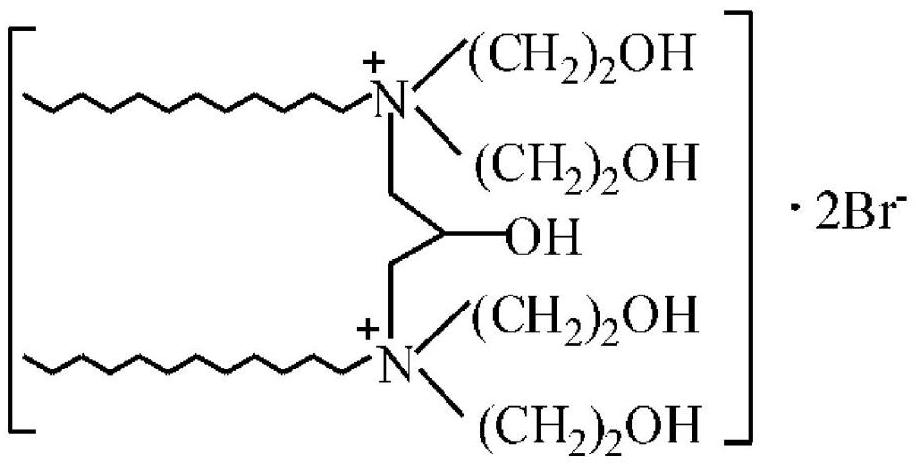

[0044] (4) Weigh diatomite with a particle size of 800-900nm, put it into deionized water and stir to form a suspension, then add an active agent, stir ultrasonically, wash the product, filter it with suc...

Embodiment 2

[0057] An environmentally friendly building insulation material, comprising the following raw materials in parts by weight: 60 parts of recycled construction waste materials, 10 parts of ordinary Portland cement, 3 parts of quicklime, 10 parts of modified diatomite, and 4 parts of lignocellulose;

[0058] Wherein, the preparation process of modified diatomite comprises the following steps:

[0059] (1) Grinding the shells to obtain shell powder with a particle size of 80-120 nm;

[0060] (2) washing the shell powder prepared in step (1) with a sodium hydrogen phosphate solution to obtain liquid shell powder;

[0061] (3) The liquid-laden shell powder obtained in step (2) is incubated at 500° C. for 10 minutes, rinsed with tap water, and dried to obtain active shell powder;

[0062] (4) Weigh diatomite with a particle size of 800-900nm, put it into deionized water and stir to form a suspension, then add an active agent, stir ultrasonically, wash the product, filter it with suc...

Embodiment 3

[0075] An environmentally friendly building insulation material, comprising the following raw materials in parts by weight: 60 parts of recycled construction waste materials, 10 parts of ordinary Portland cement, 3 parts of quicklime, 10 parts of modified diatomite, and 4 parts of lignocellulose;

[0076] Wherein, the preparation process of modified diatomite comprises the following steps:

[0077] (1) Grinding the shells to obtain shell powder with a particle size of 80-120 nm;

[0078] (2) washing the shell powder prepared in step (1) with a sodium hydrogen phosphate solution to obtain liquid shell powder;

[0079] (3) The liquid-laden shell powder obtained in step (2) is incubated at 500° C. for 10 minutes, rinsed with tap water, and dried to obtain active shell powder;

[0080] (4) Weigh diatomite with a particle size of 800-900nm, put it into deionized water and stir to form a suspension, then add an active agent, stir ultrasonically, wash the product, filter it with suc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com