The treatment method of n-acetylcysteine production waste liquid

A technology of acetylcysteine and diacetylcysteine, which is applied in the field of treatment of N-acetylcysteine production waste liquid, can solve the problems of environmental pollution, waste of resources, poor quality and the like, and achieves easy discharge standards, The effect of reducing the content of organic matter and improving the utilization rate of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

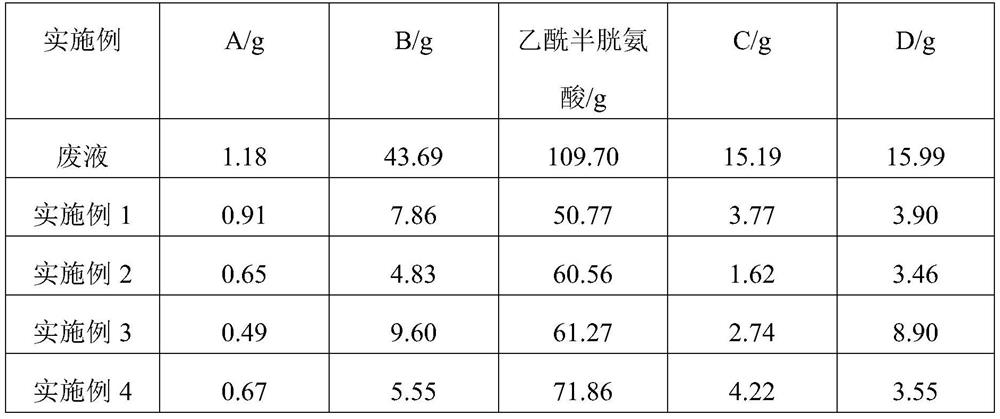

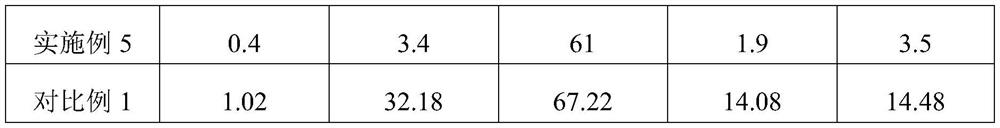

Embodiment 1

[0049] (1) Concentration

[0050] 1000 mL of waste liquid was concentrated under reduced pressure, the volume was concentrated to about 500 mL, the concentration was stopped, and the concentrated solution was transferred to the reaction vessel.

[0051] (2) Zinc powder reduction

[0052] Add 30% liquid caustic soda to the concentrated solution, adjust the pH to 3-5, add 6g of zinc powder in two times within 20 minutes, heat and stir, control the temperature to 50-60°C, and keep stirring for about 1 hour. The molar ratio of zinc powder to N,N'-diacetylcysteine in the waste liquid was 2.15:1.

[0053] (3) Acylation reaction

[0054] Add 30% caustic soda to the reaction solution to adjust pH to 8.56, control the temperature at 40-60°C, add 40.6 g of acetic anhydride dropwise, control the dropwise addition time within 20-40min, and pH 7.02 after the dropwise addition of acetic anhydride. The molar ratio of acetic anhydride to cysteine in the waste liquid is 1.10:1.

[0055...

Embodiment 2

[0062] (1) Concentration

[0063] 1000 mL of waste liquid was concentrated under reduced pressure, the volume was concentrated to about 500 mL, the concentration was stopped, and the concentrated solution was transferred to the reaction vessel.

[0064] (2) Zinc powder reduction

[0065] Add 30% liquid caustic soda to the concentrated solution, adjust the pH to 3-5, add 9g of zinc powder in two times within 20 minutes, heat and stir, control the temperature to 50-60°C, and keep stirring for about 1 hour. The molar ratio of zinc powder to N,N'-diacetylcysteine in the waste liquid was 3.2:1.

[0066] (3) Acylation reaction

[0067] Add 30% liquid caustic soda to the reaction solution to adjust pH to 8.51, control the temperature at 40-60°C, add 44.7g of acetic anhydride dropwise, control the dropwise addition time within 20-40min, and pH 7.03 after the dropwise addition of acetic anhydride. The molar ratio of acetic anhydride to cysteine in the waste liquid is 1.2:1.

[...

Embodiment 3

[0075] (1) Concentration

[0076] 1000 mL of waste liquid was concentrated under reduced pressure, the volume was concentrated to about 500 mL, the concentration was stopped, and the concentrated solution was transferred to the reaction vessel.

[0077] (2) Zinc powder reduction

[0078] Add 30% liquid caustic soda to the concentrated solution, adjust the pH to 3-5, add 9g of zinc powder in two times within 20 minutes, heat and stir, control the temperature to 50-60°C, and keep stirring for about 1 hour. The molar ratio of zinc powder to N,N'-diacetylcysteine in the waste liquid was 3.2:1.

[0079] (3) Acylation reaction

[0080] Add 30% caustic soda to the reaction solution to adjust pH to 7.60, control the temperature at 40-60°C, add 39.2 g of acetic anhydride dropwise, control the dropwise addition time within 20-40min, and pH 4.68 after the dropwise addition of acetic anhydride. The molar ratio of acetic anhydride to cysteine in the waste liquid is 1.06:1.

[0081]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com