Production method of double-component monofilaments composited and formed in spinning tanks

A technology of spinning box and compound forming, which is applied in the direction of conjugated synthetic polymer artificial filament, filament/thread forming, and melting of filament raw materials, which can solve the problem of affecting the spinning quality and the spinning process temperature cannot be reached Optimum and other issues to achieve the effect of improving spinning quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] In the prior art, usually, the composite spinning is completed in the composite spinning assembly of the spinning box. The bicomponent melt that makes up bicomponent monofilaments is composed of two different polymers. The melting points of the two polymers are different, so the corresponding optimum spinning process temperature is also different. When entering different polymer melts into the same spinning box for compounding, the temperature of the box is generally set according to the polymer with a high melting point, which leads to the fact that the spinning process temperature of the polymer with a low melting point cannot be optimal and cannot meet the spinning requirements. The rheology of the polymer required by the process directly affects the spinning quality.

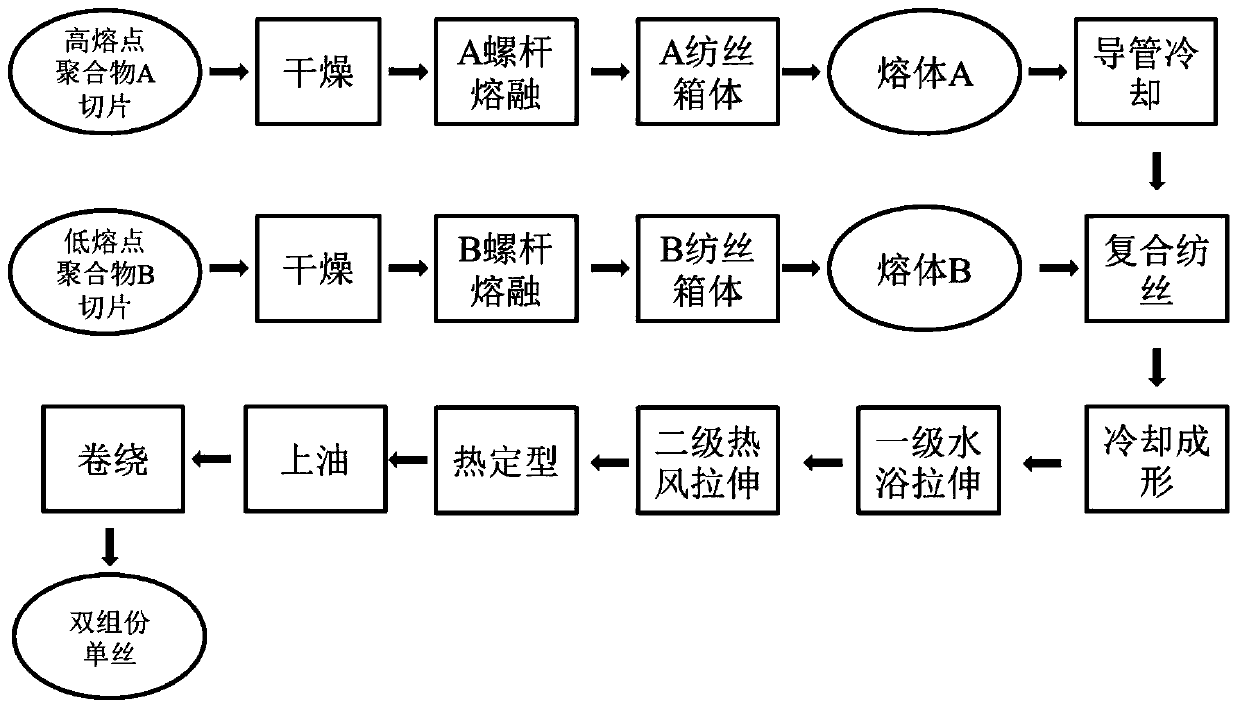

[0026] The embodiment of the present invention provides a method for preparing a bi-component monofilament compositely formed under the spinning box, which includes: cutting the dried high-melting po...

Embodiment 2

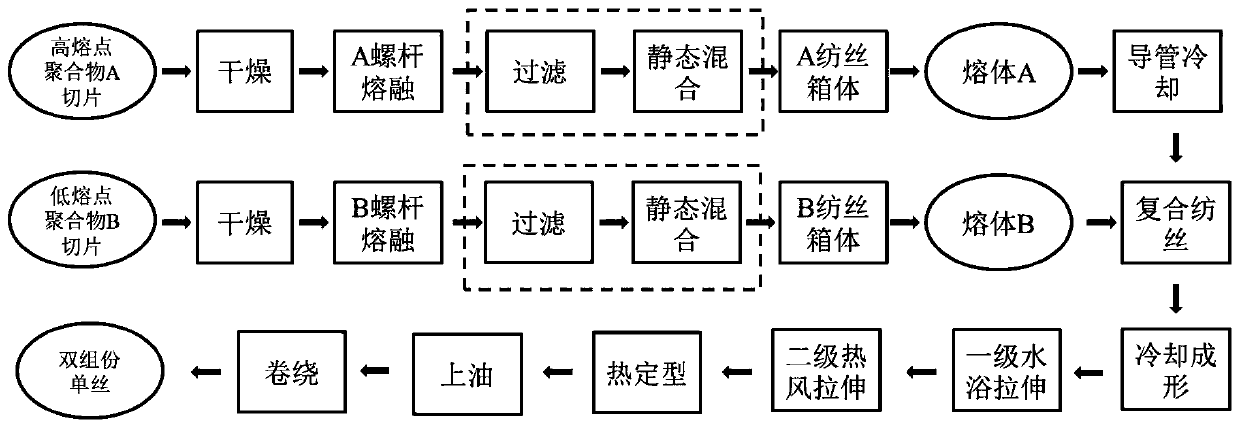

[0036] There are inevitably certain impurities in the polymer chips, which are brought into the composite spinning assembly after being melted by the screw. Due to the small size of the spinneret holes inside the composite spinning assembly, the impurities are easy to accumulate at the spinneret holes. As a result, the uniformity of the composite spinning will be adversely affected. In order to solve the above problems, the embodiment of the present invention provides the preparation method of the bi-component monofilament compositely formed under the spinning box, on the basis of Example 1, preferably, the high melting point polymer A chips go through the step "by After the A screw melts", before the step "input into the A spinning box", it is also filtered; after the low-melting point polymer B chip is passed through the step "through the B screw melting", it is in the step "input into the B spinning box". "Before, it was also filtered. Filtration treatment can purify the m...

Embodiment 3

[0040] Embodiment 3 of the present invention provides a kind of preparation method of the PA6 / PET two-component monofilament of composite forming under the spin box body, comprising:

[0041] (1) Prepare polyethylene terephthalate (PET, melting point: 290°C) slices and polyamide 6 (PA6, melting point: 140°C) slices respectively;

[0042] (2) Drying, screw melting, filtering, and static mixing are performed on the PET chips and PA6 chips respectively, and are output from the corresponding spinning boxes to obtain PET melts and PA6 melts respectively, wherein:

[0043] When drying, use a vacuum dryer with a drying temperature of 100°C; at the end of drying, the moisture content of PET chips and PA6 chips is <0.1%;

[0044] When filtering, the pore size of the filter screen using the melt filter is 40 μm, and the working pressure of the filter element is 2.5×10 6 Pa;

[0045] For static mixing, an LPD static mixer with a pipe diameter of 0.06m is used;

[0046] When the screw ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com