Method for manufacturing relative humidity sensor and relative humidity sensor

A relative humidity and sensor technology, applied in instruments, scientific instruments, measuring devices, etc., can solve the problems of heat sensitivity, low glass transition temperature, polymer materials not suitable for high temperature, etc., to achieve simplified overall assembly, not easy to aging, small volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

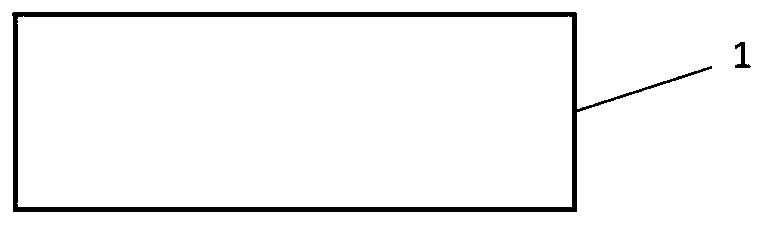

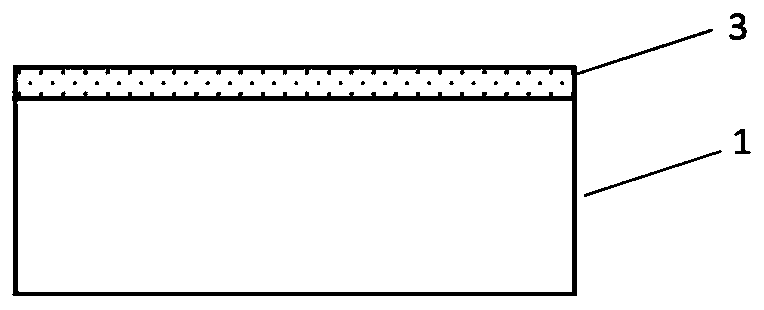

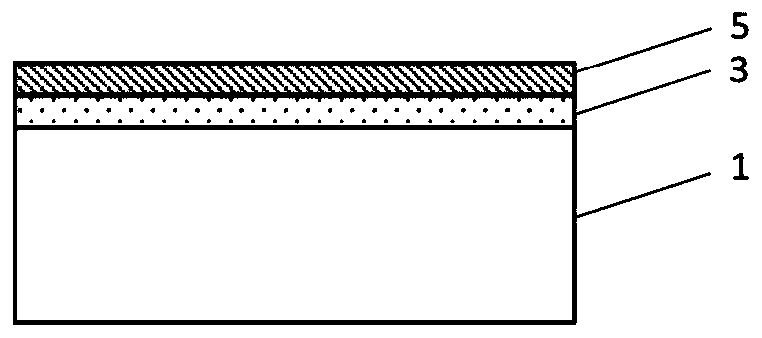

[0032] Figures 1a-1e A method of manufacturing a relative humidity sensor according to a first embodiment of the present invention is shown. It shows the formation of one relative humidity sensor, however it should be understood that the process described is a microfabrication process which allows multiple sensor structures to be formed simultaneously on one substrate (eg, one wafer).

[0033] In the following process steps, the various layers necessary to construct the relative humidity sensor will be formed. Figure 1a A substrate 1 is shown, which may be a silicon substrate with or without an oxide layer on its surface, a sapphire substrate, or any other suitable substrate used in a micromachining line. As an alternative, application specific integrated circuits (ASICs) can also be used as starting material for the method according to the invention.

[0034] Such as Figure 1b As shown, a layer is formed on or over the substrate 1 and serves as the first electrode 3 . T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com