Negative electrode material for lithium battery, preparation method of negative electrode material and lithium battery

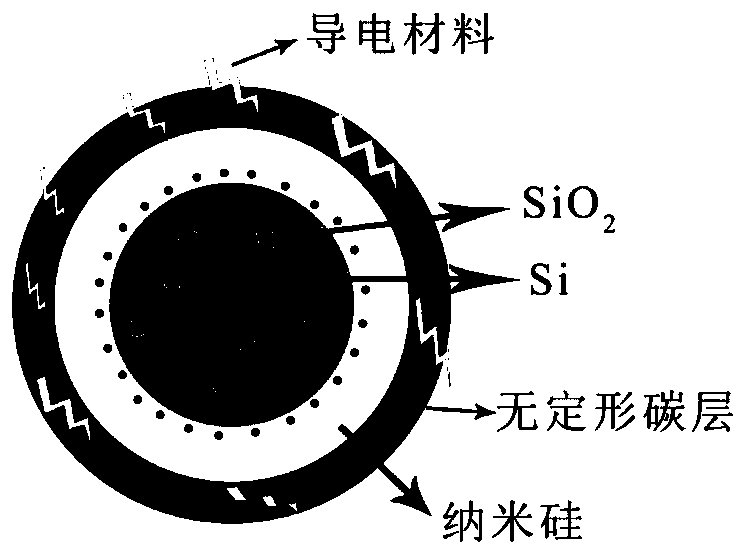

A negative electrode material, lithium battery technology, applied in battery electrodes, lithium storage batteries, negative electrodes, etc., can solve the problems of low first coulomb efficiency and low conductivity, and achieve high first charge and discharge capacity and first time Coulomb efficiency, and the preparation method is simple Easy to operate and relieve the effect of volume change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

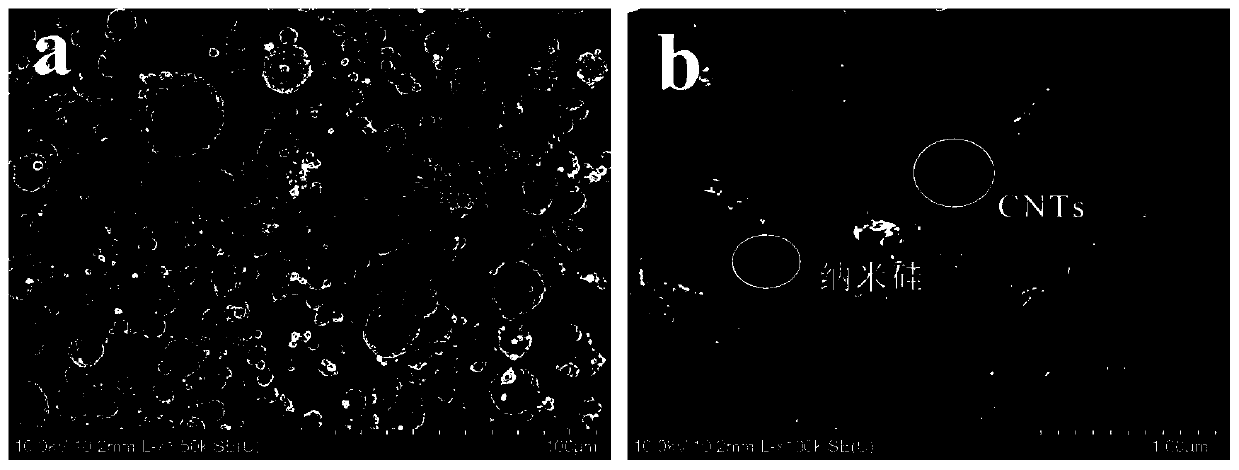

[0056] The method for preparing the negative electrode material of the lithium battery provided in this embodiment is as follows:

[0057] Place the silicon oxide in a heat treatment furnace under the protection of argon atmosphere, heat it to 1000°C and keep it for 3 hours to obtain crystallized SiO x Composite materials (ie silicon oxide composite particles). 400g SiO x The composite material and water are ball milled at a ratio of 1:9 (mass ratio), and the milling time is controlled within 1-6h, and this example is 2h to obtain SiO x Slurry, add 20g nano silicon to the slurry, and ultrasonically disperse for 30 minutes to obtain SiO x / Si slurry, to SiO x Add 16g of carbon nanotubes (ie conductive material or conductive agent) to the / Si slurry, mechanically stir to evenly disperse, then add 80g of glucose (carbon source), vacuum and stir for 30min to obtain uniformly dispersed SiO with conductive material and carbon source x / Si composite material slurry, SiO x / Si composite ma...

Embodiment 2

[0061] The method for preparing the negative electrode material of the lithium battery provided in this embodiment is as follows:

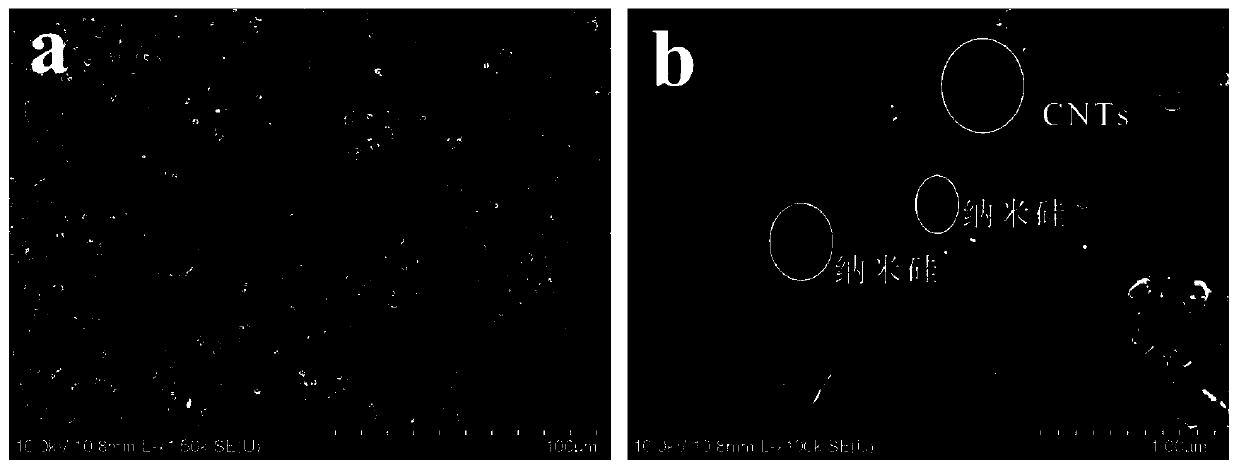

[0062] Place the silicon oxide in a heat treatment furnace under the protection of argon atmosphere, heat it to 1050°C and keep it for 3 hours to obtain crystallized SiO x Composite materials. 400g SiO x The composite material and water are ball milled at a ratio of 1:9, ball milled for 3 hours to obtain SiO x Slurry, add 20g of nano silicon to the slurry, ultrasonically disperse for 30 minutes, and then perform vacuum stirring for 30 minutes to obtain SiO x / Si slurry, to SiO x Add 16g of carbon nanotubes to the / Si slurry, mechanically stir and disperse evenly, then add 80g of styrene-butadiene rubber and stir for 60min under vacuum to obtain evenly dispersed SiO with conductive material and organic carbon source x / Si composite material slurry, SiO x / Si composite material slurry is spray-dried to obtain SiO x / Si@C composite material precursor, the...

Embodiment 3

[0065] The method for preparing the negative electrode material of the lithium battery provided in this embodiment is as follows:

[0066] Place the silicon oxide in a heat treatment furnace under the protection of argon atmosphere, heat it to 1000°C and keep it for 3 hours to obtain crystallized SiO x Composite materials. 400g SiO x The composite material and water are ball milled at a ratio of 1:9 for 4 hours to obtain SiO x Slurry, add 40g of nano silicon to the slurry, ultrasonically disperse for 30 minutes, and then perform vacuum stirring for 30 minutes to obtain SiO x / Si slurry, to SiO x Add 16g of carbon nanotubes to the / Si slurry, mechanically stir and disperse evenly, then add 80g of styrene-butadiene rubber and stir for 60min under vacuum to obtain evenly dispersed SiO with conductive material and organic carbon source x / Si composite material slurry, SiO x / Si composite material slurry is spray-dried to obtain SiO x / Si@C composite material precursor, the precursor is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com