Preparation method of integrated electrode and vanadium redox flow battery

A vanadium redox flow battery and electrode technology, which is applied in fuel cells, battery electrodes, circuits, etc., can solve the problems of weak mixing ability, large plate resistance, and large production capacity, and achieve the reduction of overall resistance value and contact resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

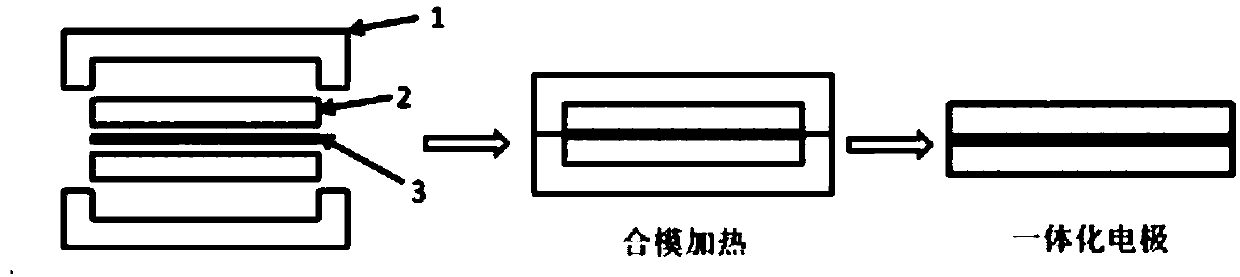

[0031] In view of the current problem that the physical contact between the bipolar plate and the carbon felt increases the overall resistance value, the embodiment of the present invention discloses a method for preparing an integrated electrode. The integrated electrode prepared by this method can reduce the overall resistance value, and at the same time It has good mechanical strength, corrosion resistance and liquid resistance. Specifically, the application provides a method for preparing an integrated electrode, comprising the following steps:

[0032] A) preparing a polymer composite bipolar plate;

[0033] B) placing the polymer composite material bipolar plate between two carbon felts, and hot pressing to obtain an integrated electrode;

[0034] The preparation method of the polymer composite bipolar plate includes:

[0035] A1) mixing the polymer resin and carbon powder, extruding the obtained mixture to obtain a polymer composite material bipolar plate;

[0036] O...

Embodiment 1

[0044] According to the mass ratio of polyethylene: carbon black = 70: 30, weigh it and put it into the mixer for mixing to obtain the mixture powder of polymer and carbon black; put the mixture powder into the twin-screw extruder to extrude The sheet is calendered into a bipolar plate with a thickness of 0.6 mm, a length of 600 mm, and a width of 500 mm.

[0045] Place the bipolar plate between two carbon felts of the same size and thickness of 6 mm, and hot press in the mold for 30 minutes, the clamping pressure is 40 MPa, and the temperature is 220 ° C. After cooling, the mold is opened to obtain an integrated electrode .

[0046] The performance of the above-mentioned integrated electrode was tested, and the thickness of the carbon felt on both sides was measured to be 5.8mm, and the electrode resistivity was 6.0Ω·cm; the integrated electrode was used to assemble an all-vanadium redox flow battery, and the voltage of the all-vanadium redox flow battery The efficiency reac...

Embodiment 2

[0048] According to the mass ratio of polypropylene: graphite = 70: 30, weigh and put it into the mixer for mixing to obtain the mixture powder of polymer and graphite; put the mixture powder into the twin-screw extruder to extrude the sheet , rolled into a bipolar plate with a thickness of 0.8mm, a length of 600mm, and a width of 500mm;

[0049] Place the bipolar plate between two carbon felts of the same size and thickness of 6 mm, and hot press in the mold for 30 minutes, the clamping pressure is 40 MPa, and the temperature is 220 ° C. After cooling, the mold is opened to obtain an integrated electrode .

[0050] The performance of the above-mentioned integrated electrode was tested, and the thickness of the carbon felt on both sides was measured to be 5.7mm, and the electrode resistivity was 7.1Ω·cm; this integrated electrode was used to assemble an all-vanadium redox flow battery, and the voltage of the all-vanadium redox flow battery The efficiency reached 83%, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com