Friction material, friction lining and preparation method thereof

A friction material and friction lining technology, applied in the field of brake materials, can solve the problems of high and stable braking torque, safety hazards of heavy trucks, etc., achieve high and stable friction performance, improve braking safety, and no burning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

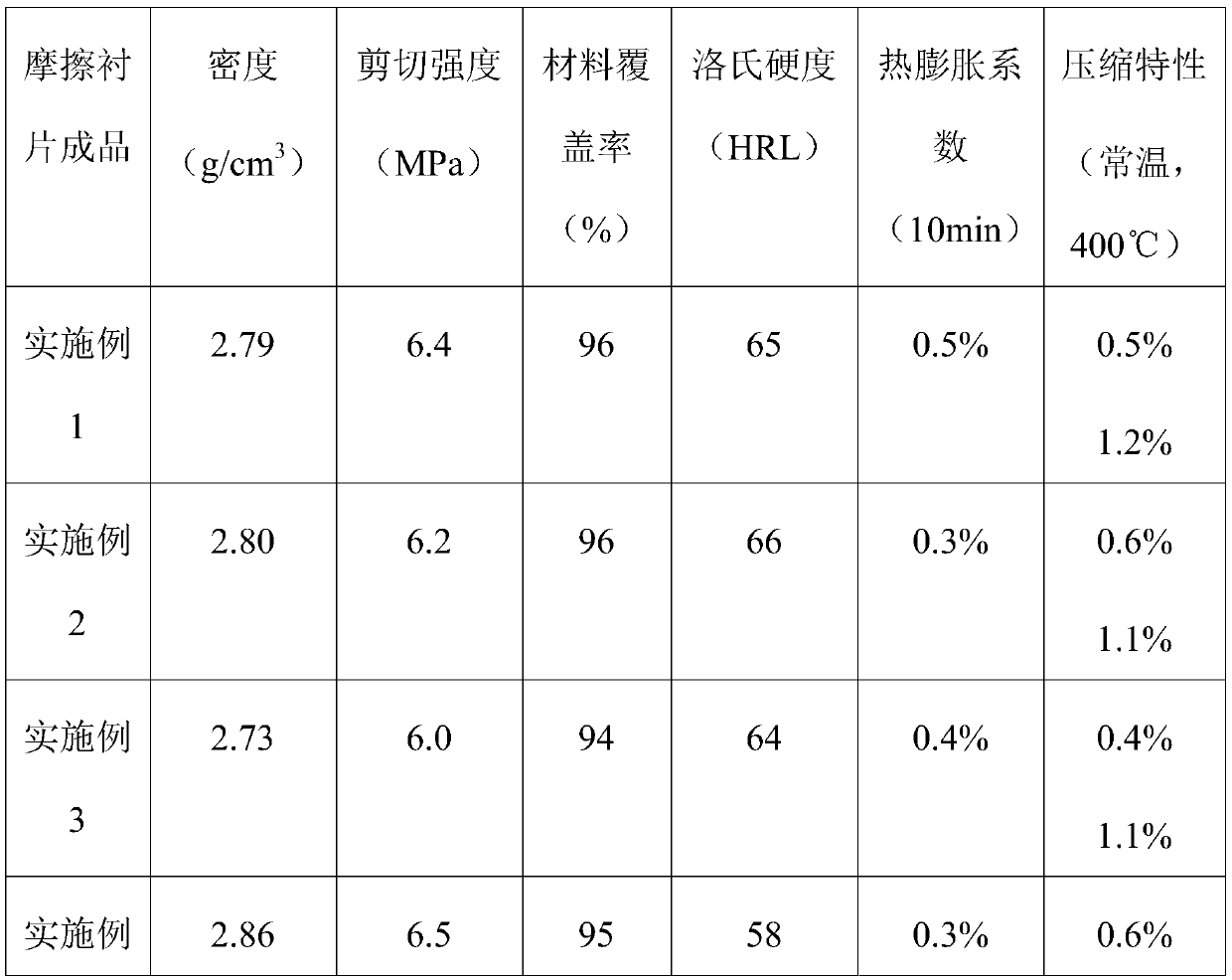

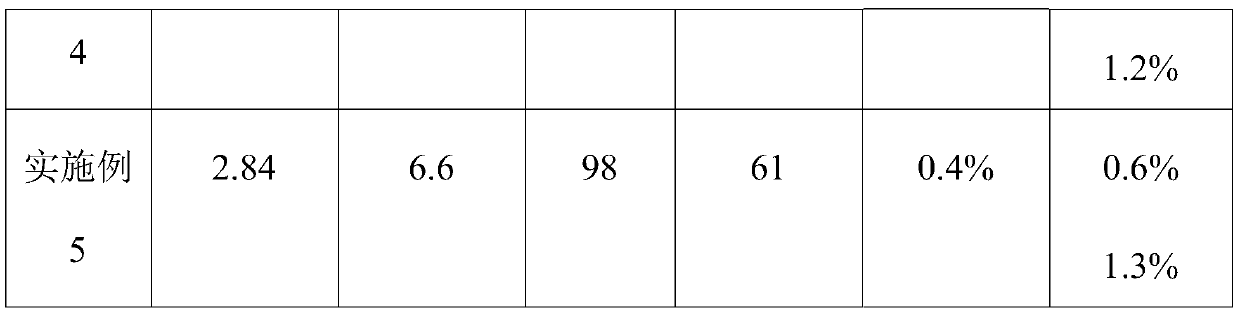

Examples

Embodiment 1

[0035] A friction material consisting of the following raw materials: 2kg of ceramic microbeads, 8kg of steel fibers, 5kg of composite mineral fibers, 7kg of bismaleimide resin, 4kg of rubber elastic particles, 6kg of granular graphite, 7kg of calcium fluoride, and 2kg of aramid pulp , titanate lamellae 6kg, light calcium carbonate 7kg, silicon carbide 3kg, calcined alumina 5kg, copper fiber 12kg, copper powder 7kg, ferrous sulfide 3kg, calcined petroleum coke 6kg, zircon sand 10kg.

[0036] A friction lining, the preparation method is as follows:

[0037] (1) Take the above-mentioned ceramic microspheres, steel fibers, composite mineral fibers, bismaleimide resin, and rubber elastic particles respectively, and mix them for 4 minutes to obtain a mixture A;

[0038] (2) Take the above-mentioned granular graphite, calcium fluoride, aramid pulp, titanate lamellae, light calcium carbonate, and silicon carbide respectively, and mix them for 8 minutes to obtain the mixture B;

[00...

Embodiment 2

[0045]A friction material consisting of the following raw materials: 2kg of ceramic microbeads, 10kg of steel fibers, 7kg of composite mineral fibers, 6kg of bismaleimide resin, 4kg of rubber elastic particles, 5kg of granular graphite, 5kg of calcium fluoride, and 5kg of aramid pulp , 7 kg of titanate lamellae, 10 kg of light calcium carbonate, 7 kg of silicon carbide, 6 kg of calcined alumina, 11 kg of red copper fiber, 6 kg of red copper powder, 7 kg of ferrous sulfide, 5 kg of calcined petroleum coke, and 10 kg of zircon sand.

[0046] A friction lining, the preparation method is as follows:

[0047] (1) Take the above-mentioned ceramic microspheres, steel fibers, composite mineral fibers, bismaleimide resin, and rubber elastic particles respectively, and mix them for 8 minutes to obtain a mixture A;

[0048] (2) Take the above-mentioned granular graphite, calcium fluoride, aramid pulp, titanate lamellae, light calcium carbonate, and silicon carbide respectively, and mix t...

Embodiment 3

[0055] A friction material consisting of the following raw materials: 3kg of ceramic microbeads, 9kg of steel fibers, 6kg of composite mineral fibers, 8kg of bismaleimide resin, 5kg of rubber elastic particles, 6kg of granular graphite, 6kg of calcium fluoride, and 4kg of aramid pulp , 7 kg of titanate lamellae, 5 kg of light calcium carbonate, 3 kg of silicon carbide, 6 kg of calcined alumina, 12 kg of red copper fiber, 7 kg of red copper powder, 6 kg of ferrous sulfide, 6 kg of calcined petroleum coke, and 8 kg of zircon sand.

[0056] A friction lining, the preparation method is as follows:

[0057] (1) Take the above-mentioned ceramic microspheres, steel fibers, composite mineral fibers, bismaleimide resin, and rubber elastic particles respectively, and mix them for 5 minutes to obtain a mixture A;

[0058] (2) Take the above-mentioned granular graphite, calcium fluoride, aramid pulp, titanate lamellae, light calcium carbonate, and silicon carbide respectively, and mix the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com